High-low pressure integrated roadway grouting reinforcement method

A technology of grouting reinforcement and high pressure grouting, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as insufficient grouting in deep rock mass, local slurry loss in shallow parts, and weakening of grouting effect. , to achieve the effect of reducing the amount of grouting, good grouting effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

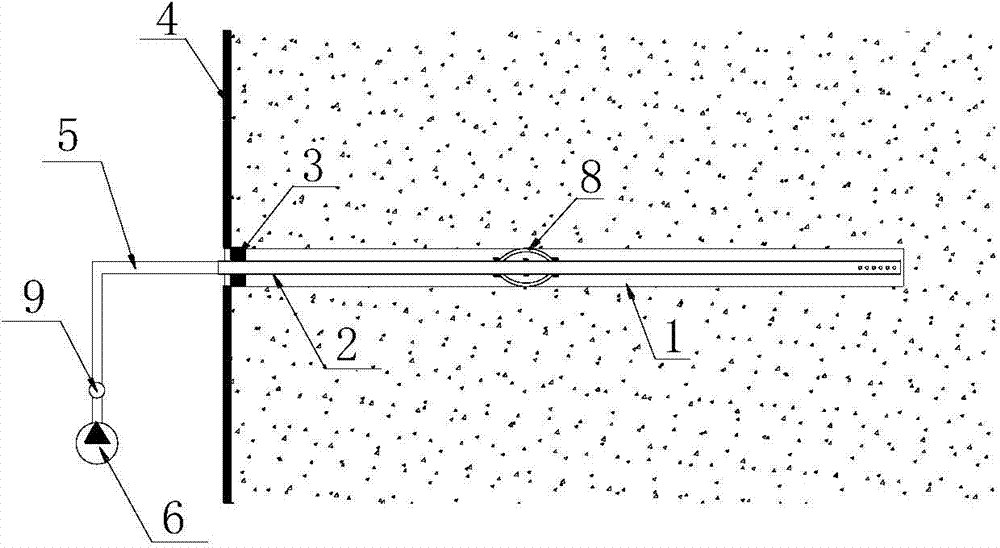

[0022] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

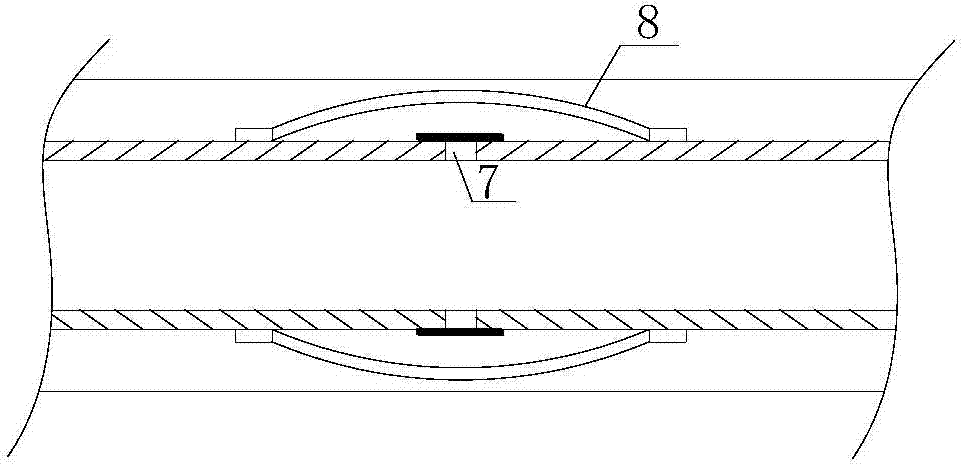

[0023] The high and low pressure integrated roadway grouting reinforcement method of the present invention: Drill hole 1 to the design depth in the surrounding rock in the area where grouting is required, clean up the residue and residual water in the hole; insert a special Grouting pipe 2, so that the front end of the grouting pipe 2 touches the bottom of the hole; the special grouting pipe 2 used is a grouting pipe with an expansion pipe 8 and a conduction hole 7, and the expansion pipe 8 is fastened to the grouting pipe. On the pipe body, the middle part of the expansion pipe 8 bulges outwards to form a gap with the pipe body. The guide hole 7 is located on the grouting pipe body 1 in the center of the expansion pipe, and the grouting pipe body 1 is surrounded by a plugging guide. The position of the elastic rubber ring of the through hole 7 and the expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com