Slurrying and preheating device for high-dryness sludge

A preheating device and high dryness technology, applied in the direction of pyrolysis treatment of sludge, etc., can solve the problems of incomplete stirring, serious lumps, and insufficient stability, and achieve convenient slurrying process, simple structure, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

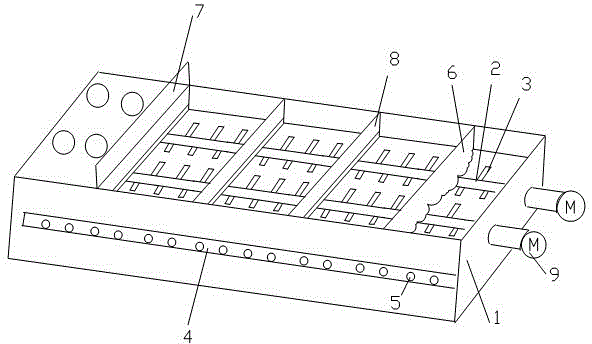

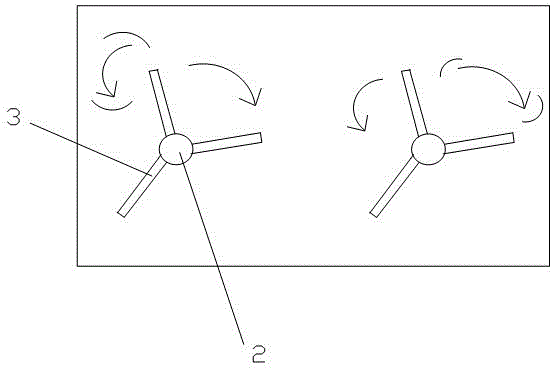

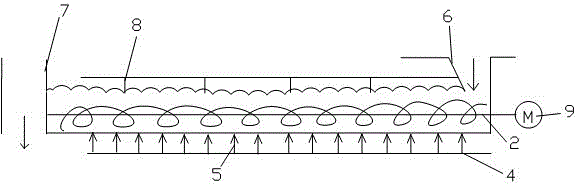

[0027] like figure 1 , a pulping and preheating device for high-dryness sludge, including a pulping device body 1, the pulping device body includes several horizontal structures 2 with parallel stirring shafts and a steam introduction pipe 4, the present In the embodiment, there are two parallel stirring shafts, and it can be 3, 4 or more during specific implementation, as long as it can play a role of stirring and driving; the horizontal structure is laid flat in the body of the slurrying device , the steam introduction pipe is located below the horizontal structure; the parallel stirring shaft of the horizontal structure is provided with a stirring paddle 3, such as figure 2 , the stirring paddles move toward each other during stirring, so that the sludge is fully stirred; the sludge is thermally hydrolyzed from the bottom of the slurry device body through the steam inlet pipe, so that the sludge can be The effect of pulping is fully obtained; the stirring paddle stirs the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com