Drill rod feeding device of cement mixing pile driver

A technology of cement-soil mixing pile and feeding device, which is applied to sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of uneven distribution of additives, uneven mixing of drill pipe, poor feeding, etc., and it is difficult to supply slurry. Insufficient, reducing the difficulty of drilling, the effect of smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

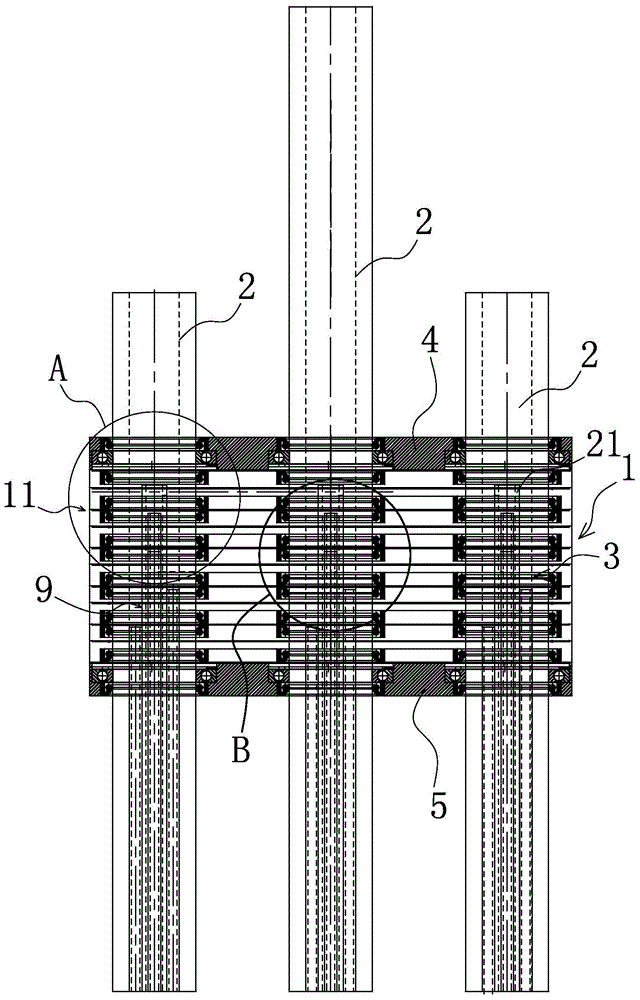

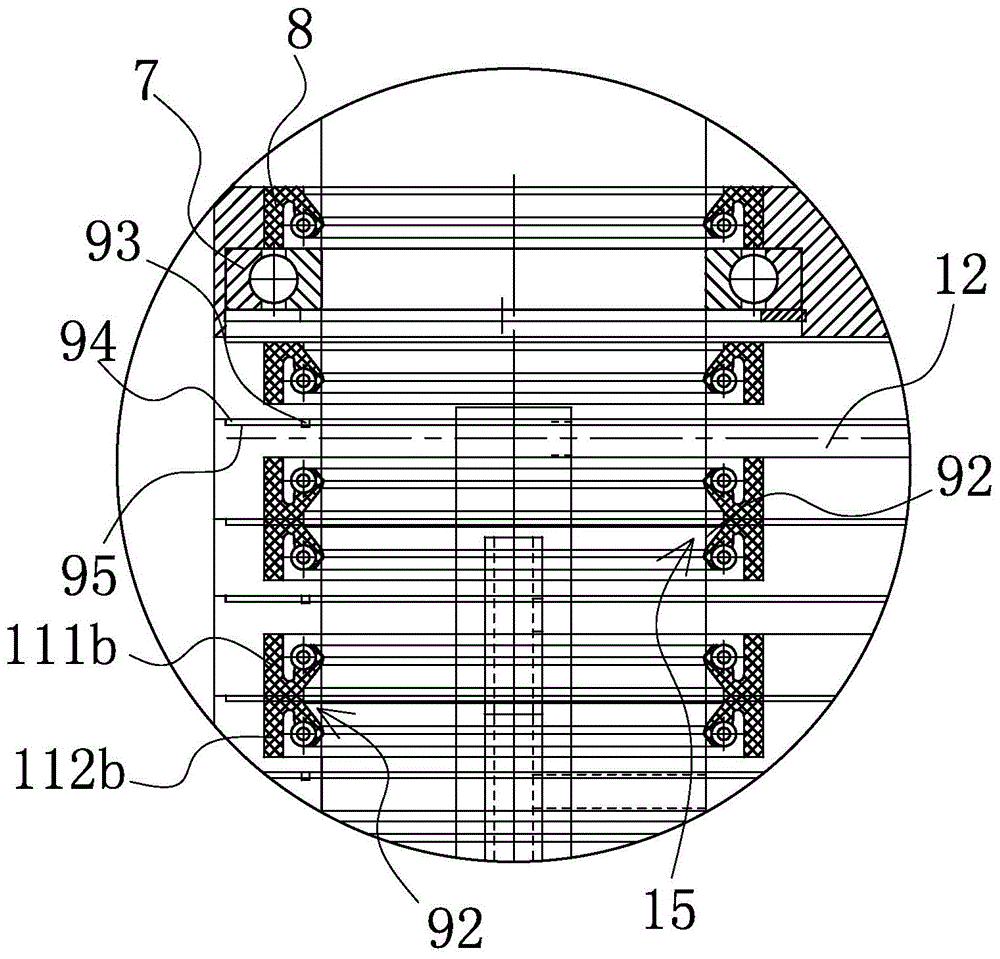

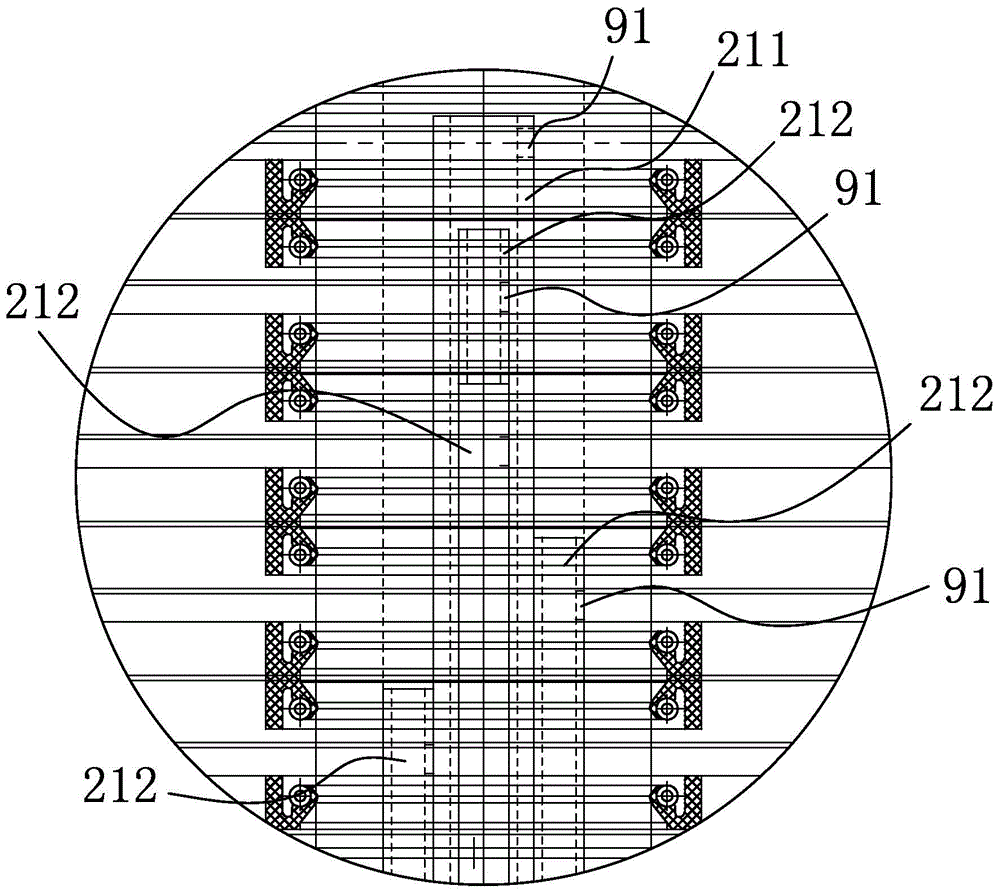

[0023] Such as Figure 1-5 As shown, the drill pipe feeding device of the cement-soil mixing pile machine includes a cloth sealing box 1, and the cloth sealing box 1 is provided with at least two distributing flow channels 12 arranged horizontally from top to bottom sequentially. The body 1 is provided with at least three through holes 15 arranged vertically and not on the same straight line, any one through hole 15 and any two remaining through holes 15 not on the same straight line as the through hole 15 They are connected successively to form a triangular structure. Each through hole 15 has at least two distributing holes 14 corresponding to the distributing flow channel 12 one-to-one. The through hole 15 is pierced with a drill rod 2 that can rotate in a circumferential direction, and the drill rod 2 There is a conveying structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com