Additive composition applicable to viscosity reduction of oil-based drilling fluid and application thereof, and oil-based drilling fluid and application thereof

A composition and additive technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as difficult to control, apparent viscosity and plastic viscosity beyond the reasonable range, so as to save drilling cost, reduce drilling difficulty, The effect of preventing downhole accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the diblock copolymer of the present invention preferably includes:

[0045] (1) In the presence of a chain transfer agent and a first azo initiator, in a first organic solvent, a compound represented by formula (1') is prepared and polymerized to obtain a polymer with a number average molecular weight of 2000-10000 A; (2) In the presence of a second azo initiator, in a second organic solvent, polymer A and the compound represented by formula (2') are copolymerized;

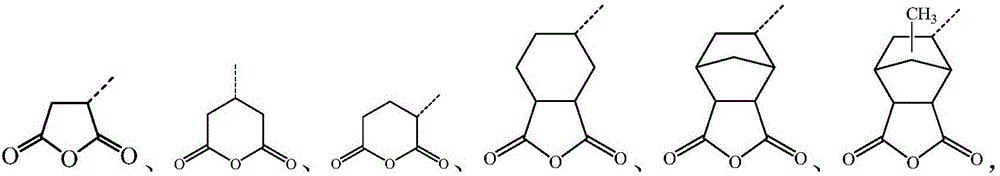

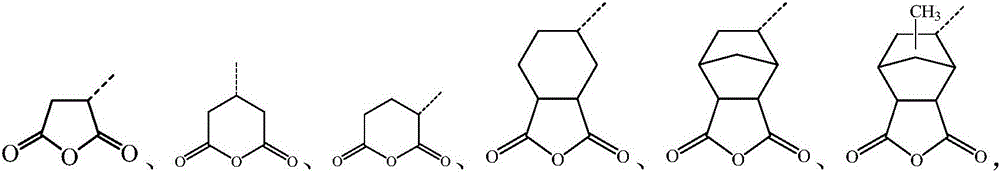

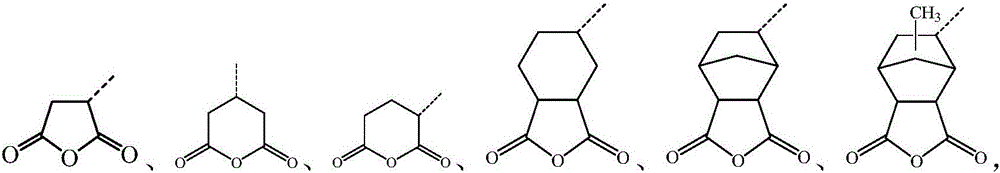

[0046] Formula 1') Formula (2')

[0047] Where R 1 , R 1' , R 4 , R 4' And R 6 Each independently selected from H and C1-C6 alkyl; R 2 And R 2' Each independently selected from H, C1-C6 alkyl, -O-C(O)-R 3 And -COOR 3 , And R 2 And R 2' At least one is selected from -O-C(O)-R 3 Or -COOR 3 , R 3 Alkyl selected from C1-C6; R 5 X is selected from C1-C8 alkylene; X is selected from -NH- or -O-; X'is selected from halogen. In the present invention, the halogen may be F, Cl, Br, I, etc., for...

preparation example 1

[0124] (1) Molar ratio of the reactant to tetraethylenepentamine: linoleic acid=1:2.2 (that is, the molar ratio of the amount of tetraethylenepentamine based on the primary amine group to the amount of linoleic acid is 1:1.1) Mix and stir at 250r / min for 40min, then adjust the pH of the resulting mixture to 9, and then react at 230°C for 3 hours, while using a water trap to separate water, and then cool to room temperature;

[0125] (2) Mix the reaction product of step (1) with malonic acid (the molar ratio of the amount of tetraethylenepentamine to the amount of malonic acid is 1:0.6), and then adjust the pH of the resulting mixture to 8. Then, it was stirred and reacted at a speed of 400r / min for 6h at 90°C to obtain emulsifier A1. After infrared, hydrogen nuclear magnetic resonance spectrum and carbon spectrum analysis and detection, the emulsifier A1 contains amide groups, unsaturated double bonds and carboxyl groups, and has a comb-shaped structure.

[0126] Preparation examp...

preparation example 2

[0135] (1) Dissolve 16 g (110 mmol) of dimethyl maleate and 1.09 g (3 mmol) of chain transfer agent 2-(dodecyl trithiocarbonate)-2-methylpropionic acid (DMP) In 40mL of benzene, and bubbling with nitrogen for 50min, then add 0.32g (1.2mmol) of the initiator azobisisobutamidine hydrochloride and react at 70℃ for 3.5h, and then distill under reduced pressure to remove the solvent and unreacted monomer to obtain 16.4 g viscous liquid PDM-1. The number average molecular weight is 5400, and the molecular weight distribution index is 1.3.

[0136] (2) Dissolve 29.2g (130mmol) of (3-acrylamidopropyl)trimethylammonium chloride and 16.4g of PDM-1 in 60mL DMF, and add nitrogen gas for 50 minutes, and then add the initiator azobisisobutyl 0.14g (0.5mmol) of amidine hydrochloride was reacted at 110°C for 22h, and cooled to room temperature to terminate the polymerization. The crude product was precipitated in anhydrous methanol, filtered and dried after repeated three times to obtain the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com