Laser rock breaking method and device applied to drilling

A rock-breaking device and laser technology, applied in the field of drilling and rock-breaking devices, to achieve the effects of saving manpower, improving drilling efficiency and quality, and high rock-breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

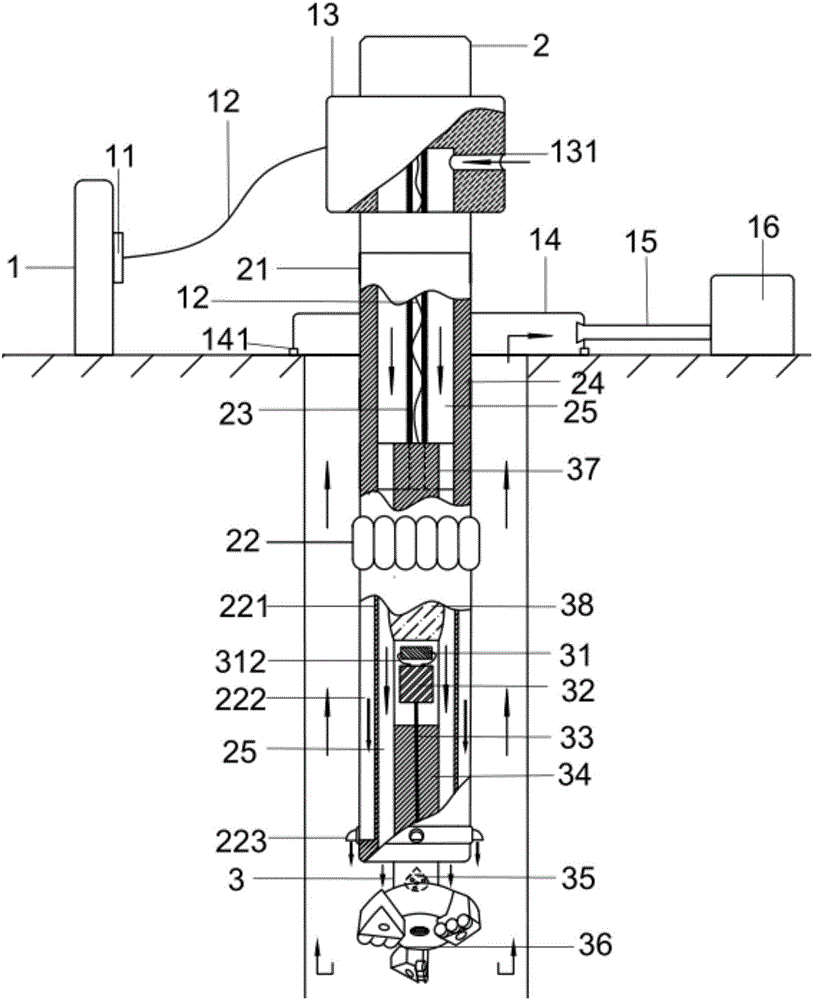

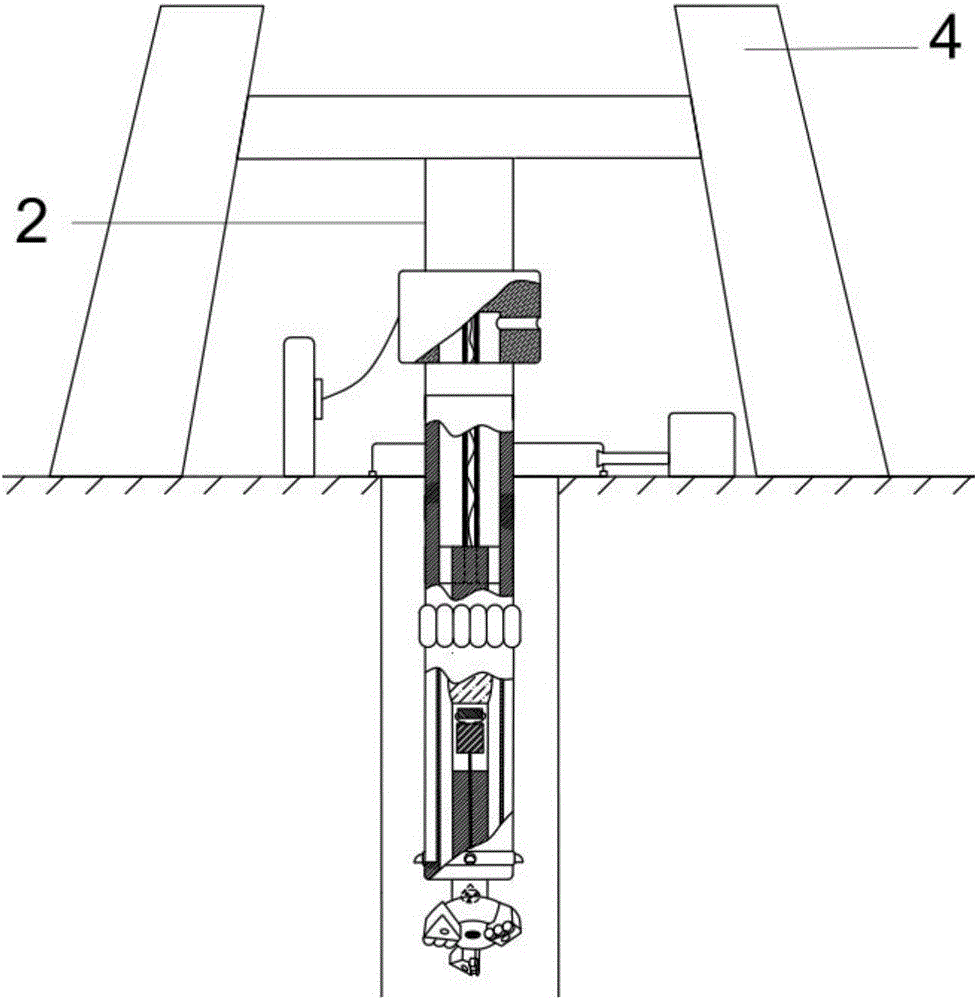

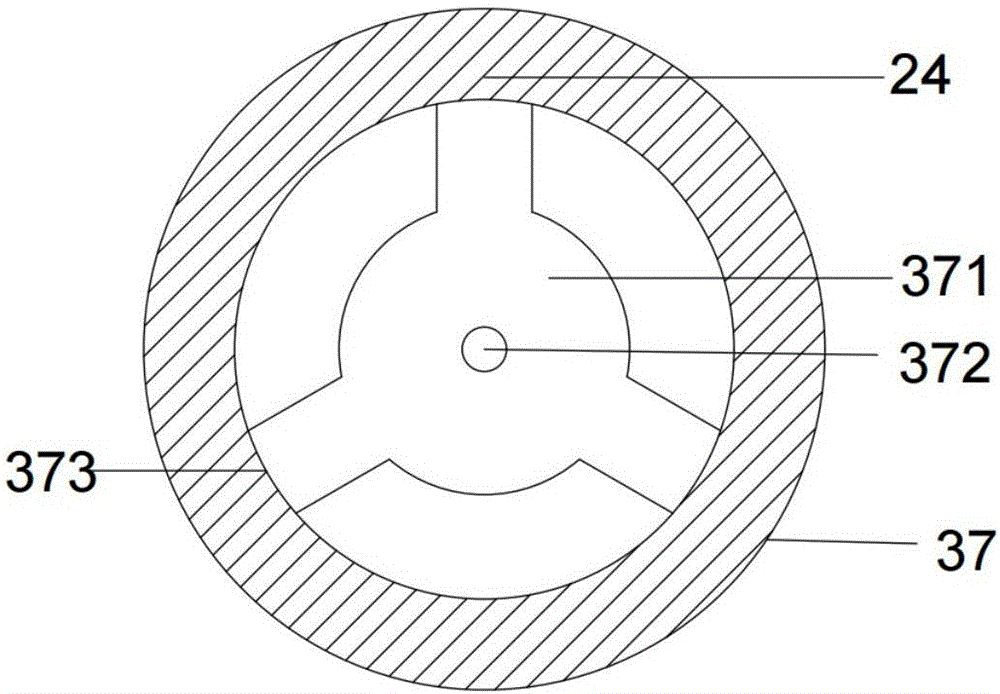

[0025] A laser rock breaking method and device for drilling, which includes a chip removal mechanism 1 , an external drill pipe 2 and an internal drill pipe 3 . The chip removal mechanism 1 includes a power supply 11, electric wires 12, an air compressor 13, a suction cup 14, a pressure-resistant pipeline 15 and a suction pump 16; the external drill pipe 2 has a liquid nitrogen storage tank 22 and an atomizing nozzle 223, The external drill pipe 2 has a liquid nitrogen channel 222, electric wires 12, protective layer 23 and gas circulation area 25, and the external drill pipe 2 does not rotate; the internal drill pipe 3 includes a downhole motor 38, a downhole power supply 31 , laser transmitter 32, fiber optic cable 33, tapered beam splitter 35, laser head 352, drill bit 36 and laser hole (central laser hole 361 and side laser hole 362), descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com