Method for separating multiple layers of materials attached with OCA (Optically Clear Adhesive) through laser

A multi-layer material and optical adhesive technology, applied in the field of laser applications, can solve problems such as uncontrollable heating temperature, secondary solidification, and difficulty in applying laser processing technology to display screens, achieve efficient and non-destructive separation, protect the environment, and reduce secondary solidification. effect of phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below through the embodiments in conjunction with the accompanying drawings, so as to better understand the present invention.

[0025] The technical solution of the present invention uses the oil-conducting laser processing technology to separate the OCA optical glue, which has significant advantages compared with the existing diamond wire or liquid nitrogen cooling separation technology, and can perfectly separate the OCA optical glue between the liquid crystal screen and the touch screen. Moreover, the liquid crystal screen and the touch screen are not damaged, and the separation efficiency is high.

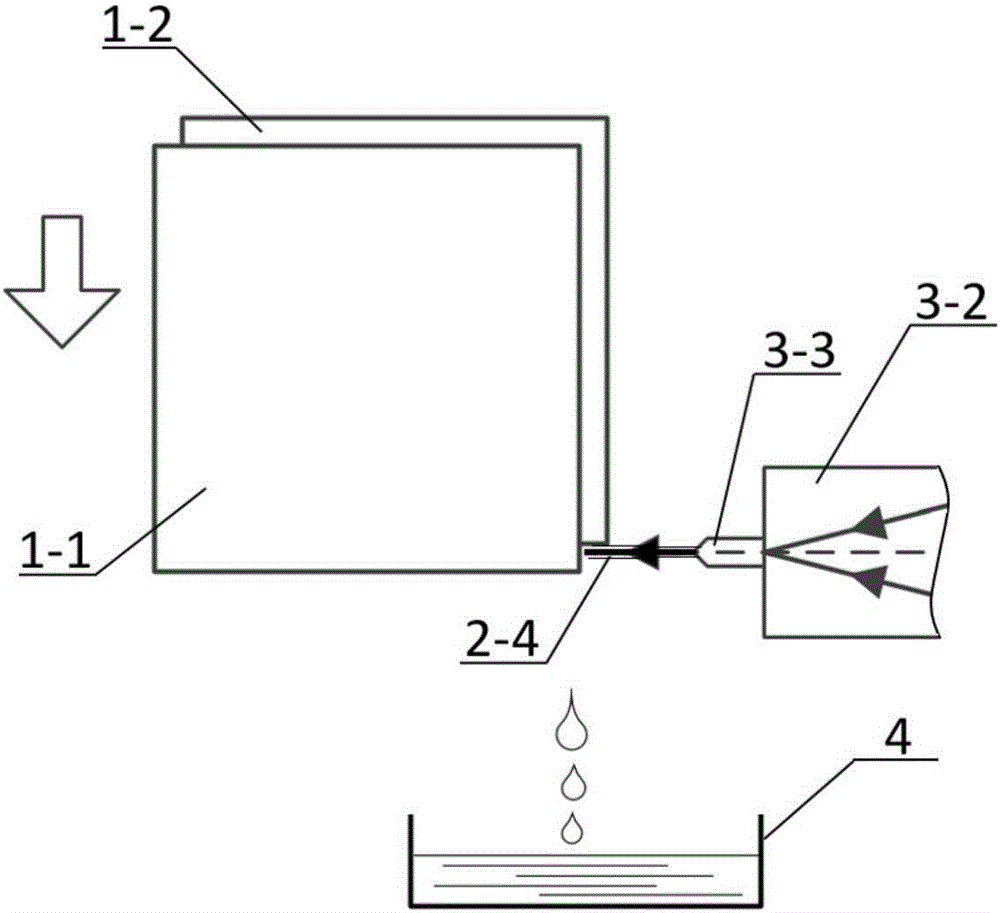

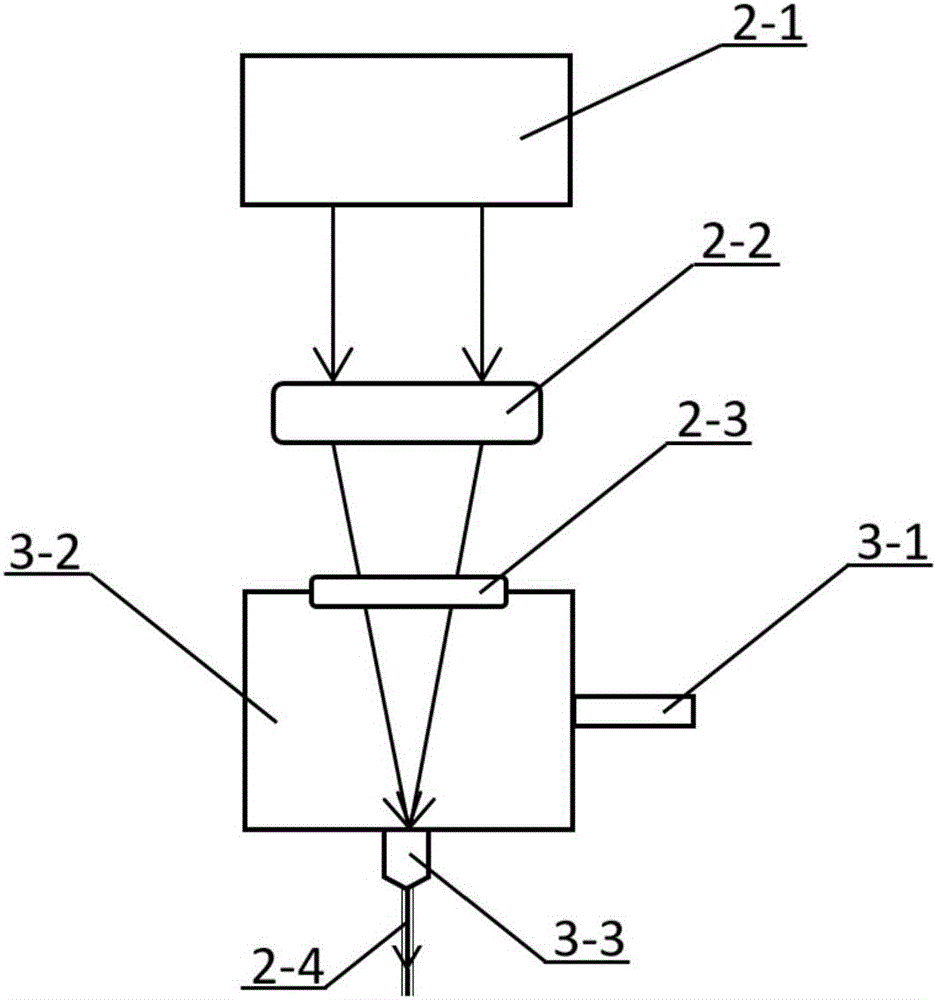

[0026] Such as figure 1 Shown is a schematic diagram of the principle of a method for laser separation of multi-layer materials bonded by OCA optical glue in an embodiment of the present invention. The multi-layer materials processed in this embodiment are liquid crystal screen 1-1 and touch scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com