Drill rod distribution structure of cement soil mixing pile driver

A technology of cement-soil mixing piles and pile drivers, which is applied in the direction of earth drilling, foundation structure engineering, sheet pile walls, etc., can solve the problems of cement-soil mixing piles such as poor pull-out resistance, uneven mixing, and low construction efficiency, and achieve The drilling difficulty is small, the mixing is uniform, and the effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

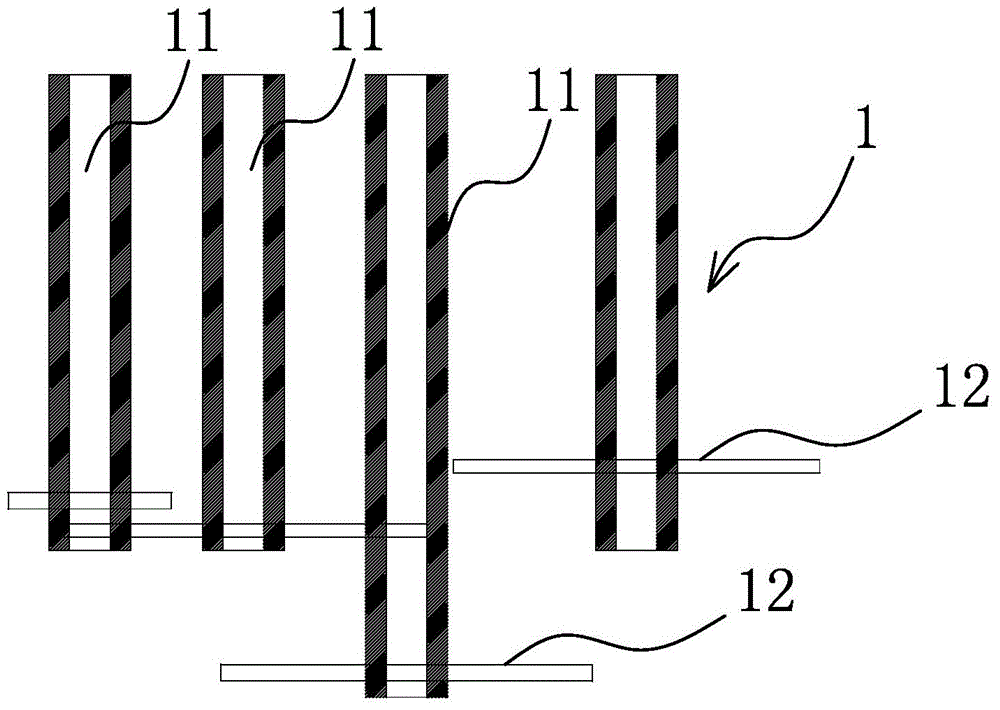

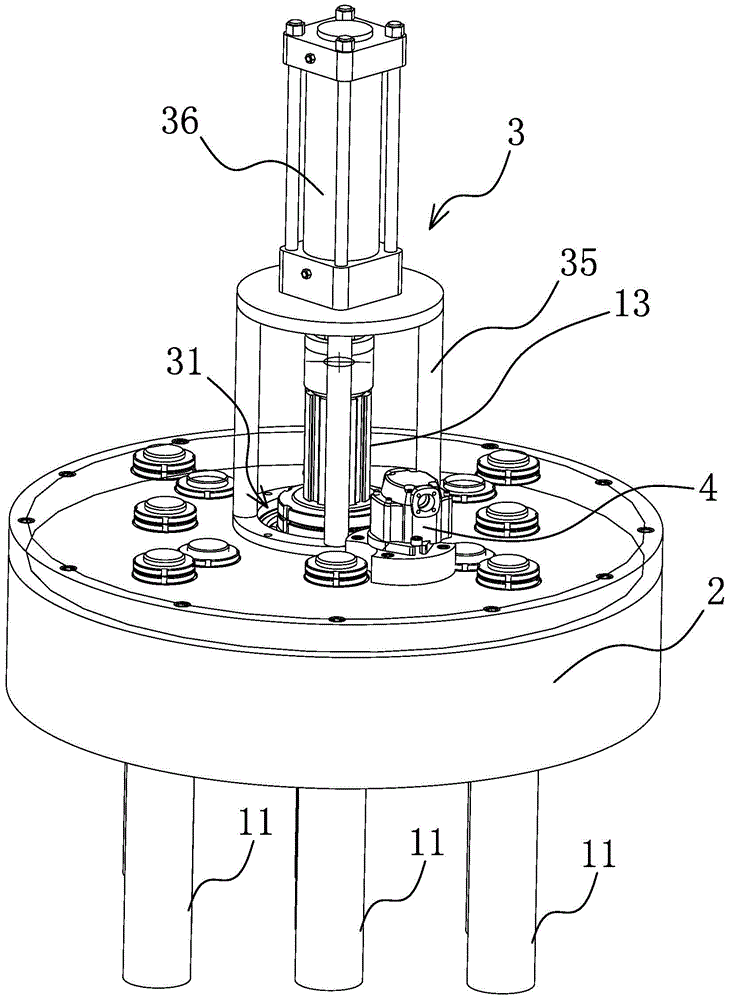

[0026] like Figure 1-2 As shown, the drill pipe distribution structure of the cement-soil mixing pile driver includes a drill pipe assembly 1 having at least three drill pipe bodies 11 that can rotate circumferentially and are vertically arranged, and each drill pipe body 11 is provided with a number of stirring body 12, the projection of the centerline of the drill pipe body 11 in the drill pipe assembly 1 in the vertical direction is not on the same straight line, and the projections of any three centerlines in the drill pipe assembly 1 in the vertical direction are not on the same straight line The centerlines of the drill pipe bodies 11 are connected successively to form a triangular structure, and the drill pipe bodies 11 are vertically dislocated one by one. Obviously, the drill pipe bodies 11 in each drill pipe assembly 1 are not located on the same straight line, which increases the construction time. The perimeter of the cross-section of the cement-soil mixing pile i...

Embodiment 2

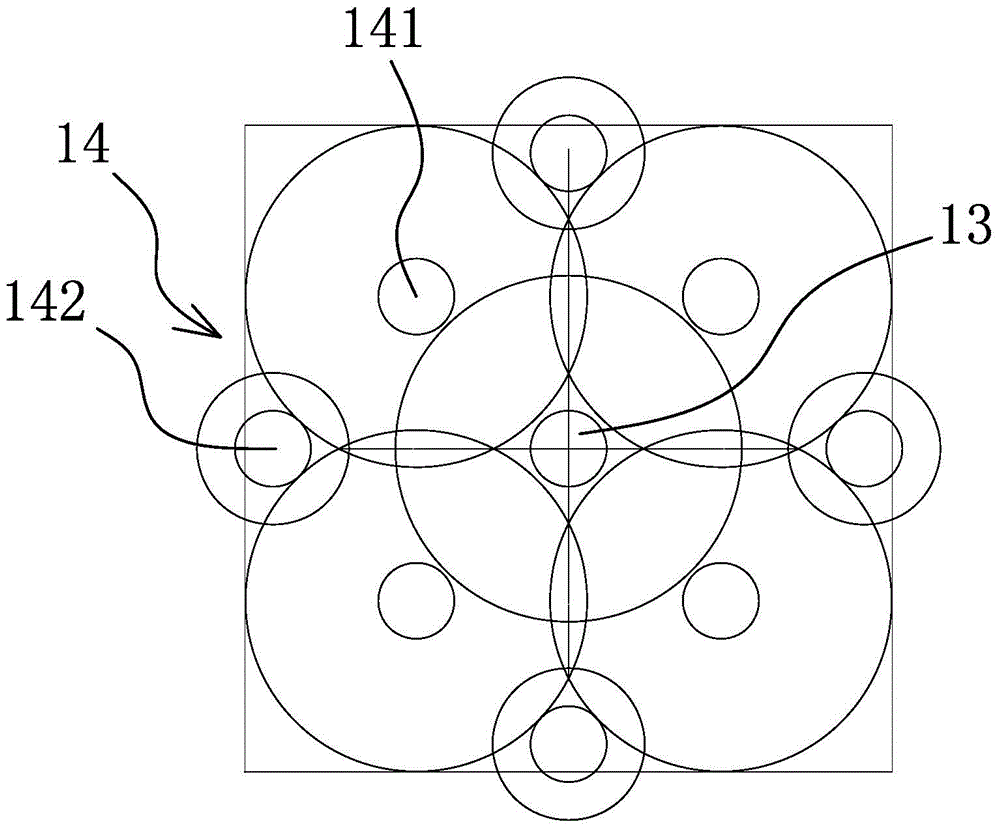

[0034] like Figure 6 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1. The difference is that the main drill rods 13 and auxiliary drill rods 14 in this embodiment are arranged in a rectangular array. Preferably, the The quantity of main drilling rod 13 is one, and the quantity of auxiliary drilling rod 14 is eight, and because main drilling rod 13 and auxiliary drilling rod 14 are arranged in a rectangular arrangement, so that one step can drill approximately rectangular boreholes, like this The cross-sectional area of the cement-soil mixing pile is increased.

Embodiment 3

[0036] like Figure 7 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1. The difference is that the auxiliary drill pipe 14 in this embodiment is arranged in a ring shape with the main drill pipe 13 as the center of circle and evenly distributed, for example , the quantity of auxiliary drilling rod 14 here is four, and the quantity of main drilling rod 13 is one and is arranged on the center of auxiliary drilling rod 14, so that one step can get out the approximately rectangular borehole, increased cement-soil like this The cross-sectional area of the mixing pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com