MEMS silicon-based membrane hole atomizing core and manufacturing method thereof

A manufacturing method and atomizing core technology, applied in tobacco and other directions, can solve the problems of poor process controllability, easy liquid frying, uneven heating, etc., to reduce the difficulty of opening holes, control the manufacturing process, and solve the problem of local overheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

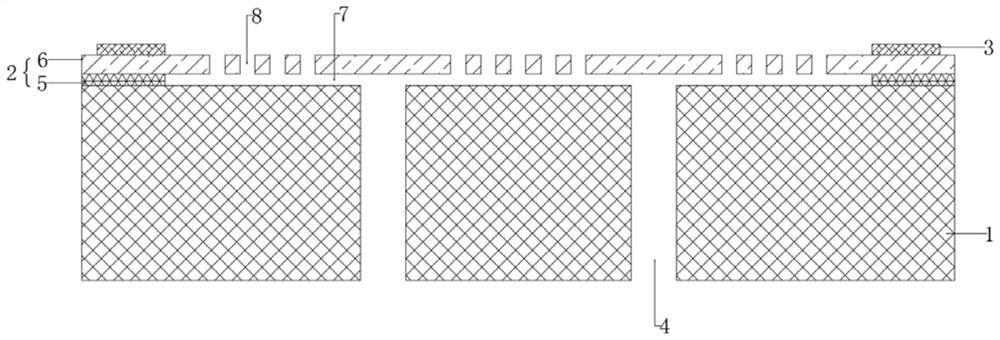

[0063] S01: preparing a silicon substrate sheet 1 with a thickness of 300 μm;

[0064] S02: using PECVD method, depositing a first layer of silicon oxide 5 on the silicon substrate 1, and depositing a first layer of polysilicon 6 on the first layer of silicon oxide 5;

[0065] S03: performing photolithography and etching on the first layer of polysilicon 6 to etch the primary atomization hole 8;

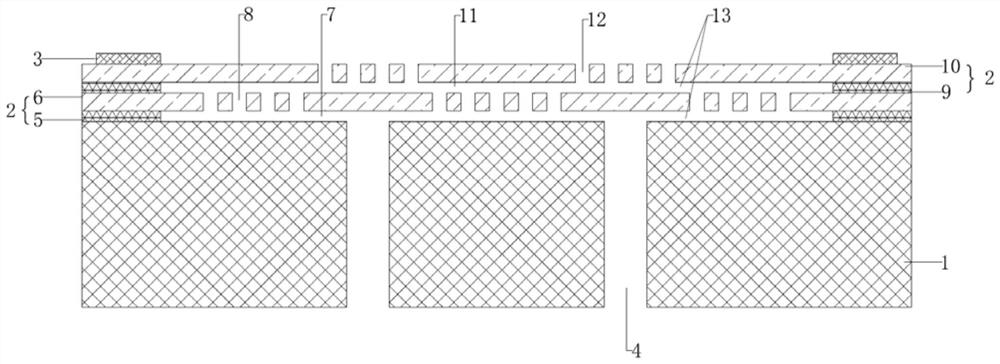

[0066] S04: Deposit a second layer of silicon oxide 9 on the first layer of polysilicon 6 by PECVD, and deposit a second layer of polysilicon 10 on the second layer of silicon oxide 9;

[0067] S05: Deposit a metal electrode 3 on the second layer of polysilicon 10, the deposited metal is Ti / Au, and make a specific pattern through a dry etching process;

[0068] S06: performing photolithography and etching on the second layer of polysilicon 10 to etch out secondary atomization holes 12;

[0069] S07: performing photolithography and etching on the back side of the silicon substrate 1...

Embodiment 2

[0072] S01: preparing a silicon substrate sheet 1 with a thickness of 300 μm;

[0073] S02: using LPCVD method, depositing a first layer of silicon oxide 5 on the silicon substrate 1, and depositing a first layer of polysilicon 6 on the first layer of silicon oxide 5;

[0074] S03: performing photolithography and etching on the first layer of polysilicon 6 to etch the primary atomization hole 8;

[0075] S04: Deposit a second layer of silicon oxide 9 on the first layer of polysilicon 6 by using LPCVD, and deposit a second layer of polysilicon 10 on the second layer of silicon oxide 9;

[0076] S05: Deposit a metal electrode 3 on the second layer of polysilicon 10, the deposited metal is Ti / TiN / Pt, and make a specific pattern through a wet etching process;

[0077] S06: performing photolithography and etching on the second layer of polysilicon 10 to etch out secondary atomization holes 12;

[0078] S07: performing photolithography and etching on the back side of the silicon s...

Embodiment 3

[0081] S01: Prepare a silicon substrate sheet 1 with a thickness of 400 μm;

[0082] S02: using PECVD method, depositing a first layer of silicon oxide 5 on the silicon substrate 1, and depositing a first layer of polysilicon 6 on the first layer of silicon oxide 5;

[0083] S03: performing photolithography and etching on the first layer of polysilicon 6 to etch the primary atomization hole 8;

[0084] S04: Deposit a second layer of silicon oxide 9 on the first layer of polysilicon 6 by using LPCVD, and deposit a second layer of polysilicon 10 on the second layer of silicon oxide 9;

[0085] S05: Deposit a metal electrode 3 on the second layer of polysilicon 10, the deposited metal is Ti / Au, and make a specific pattern through a dry etching process;

[0086] S06: performing photolithography and etching on the second layer of polysilicon 10 to etch out secondary atomization holes 12;

[0087] S07: performing photolithography and etching on the back side of the silicon substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com