Method for treating landslide projects through combining chemical electroosmosis method with micro anti-slide piles

An anti-sliding pile and electro-osmosis technology, which is applied in basic structure engineering, excavation, sheet pile wall, etc., to achieve the effect of simple construction process, easy quality control, and improvement of shear strength coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below with reference to the drawings. The protection scope of the present invention is not limited to the description of this embodiment.

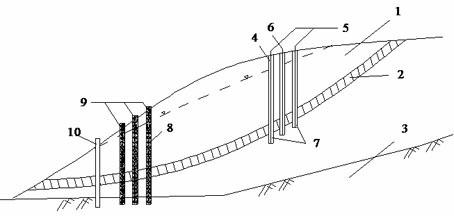

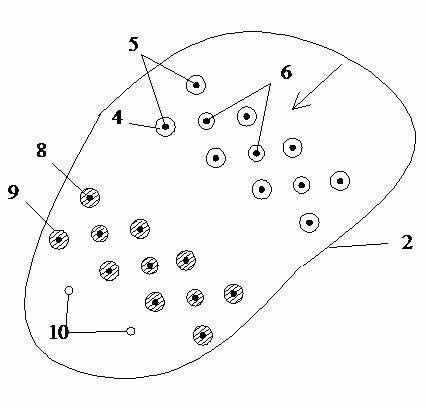

[0019] Such as figure 1 with figure 2 As shown, during implementation, a lateral inclined pipe 10 is set under the landslide body to monitor the displacement changes of the landslide body before, during, and after the treatment in real time, and play a role in guiding the construction and evaluating the treatment effect; the lateral inclined pipe 10 It is necessary to cross the bottom of the potential sliding zone 2 between the landslide body 1 and the stable body, and drive into the bedrock 3, and the distance from the borehole 4 is between 2-3 m. Determine the specific location and trend of the potential landslide zone 2 according to the geological survey, and determine the depth of the borehole 4 according to the design requirements. The depth of the bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com