Novel polymeric oil-displacing agent for improving recovery ratio and application thereof

A polymer and oil displacement agent technology, applied in the field of new polymer oil displacement agents, to achieve good water phase permeability, low cost, good injection and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 polymer oil displacement agent

[0046] 1. Synthesis of hydrophobic monomer dimethyl allyl p-hexadecyl benzyl ammonium chloride:

[0047] Add an appropriate amount of paraformaldehyde, anhydrous zinc chloride and concentrated hydrochloric acid into the three-necked flask, heat and stir, when the temperature rises to 60 ° C, add hexadecylbenzene, and quickly pass through the concentrated sulfuric acid and sodium chloride For the dry hydrogen chloride gas produced by the reaction, the amount of gas introduced is controlled by the drip rate of concentrated sulfuric acid, and the excess gas is absorbed with water. The reaction was completed after 6 hours. After cooling, the liquid was separated in a separatory funnel. The organic layer was washed twice with 10% aqueous sodium carbonate solution and three times with distilled water, then dried with anhydrous sodium sulfate, filtered, and excess hexadecane was evaporated. Benzene, and finally ...

Embodiment 2

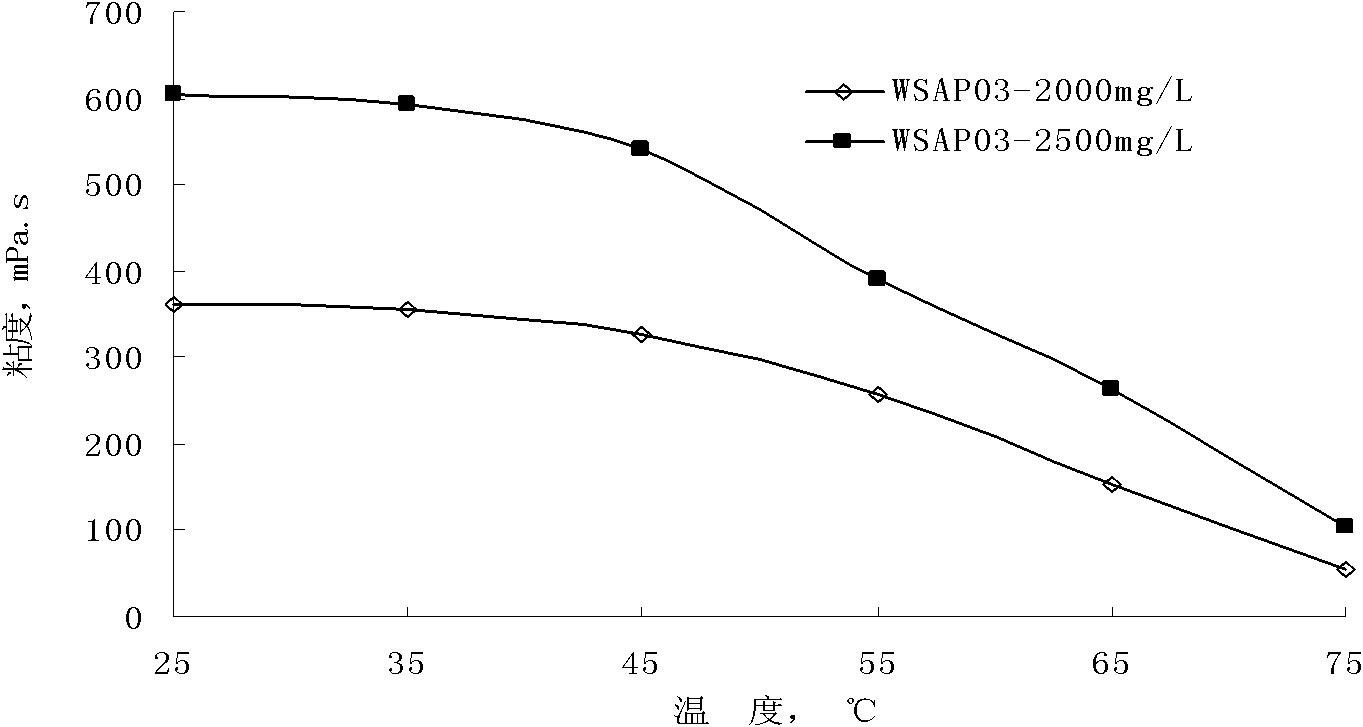

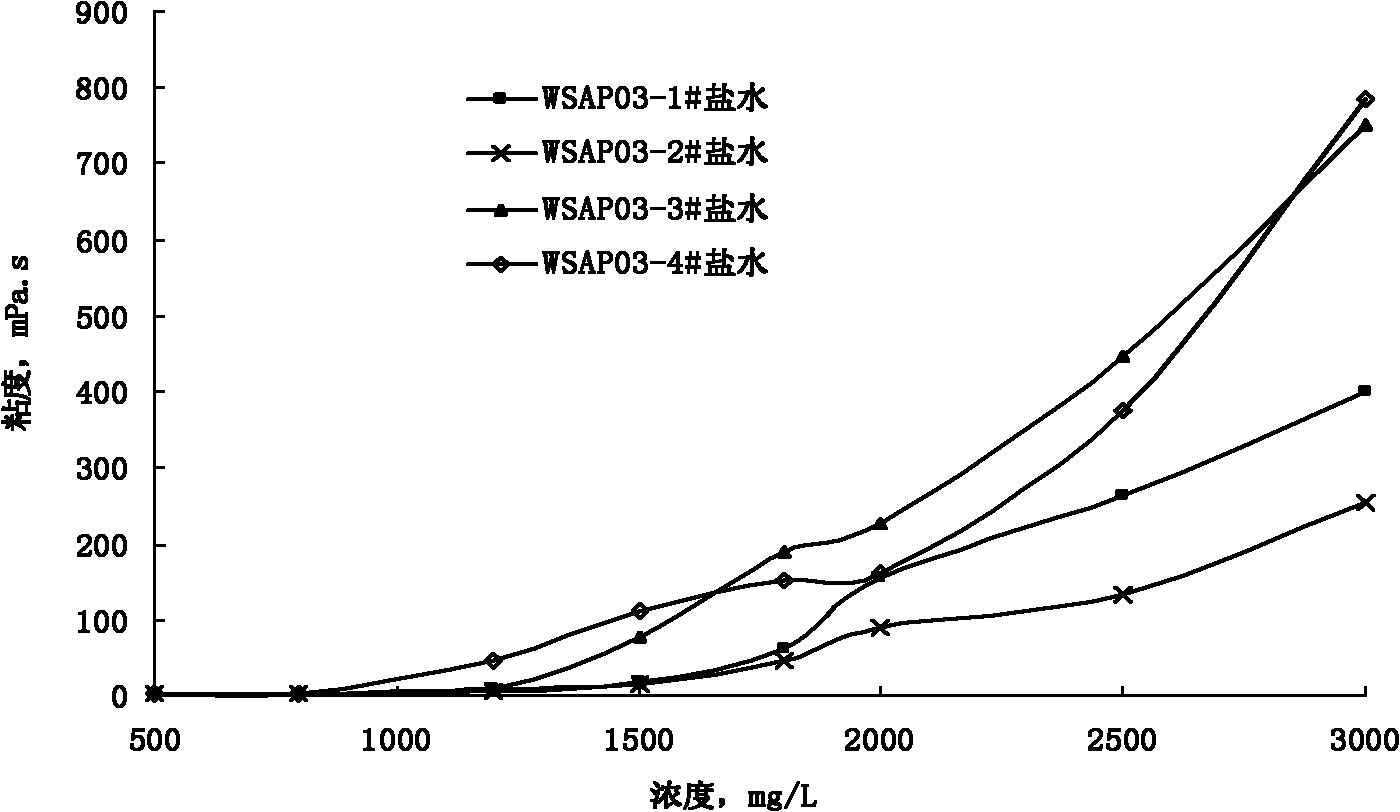

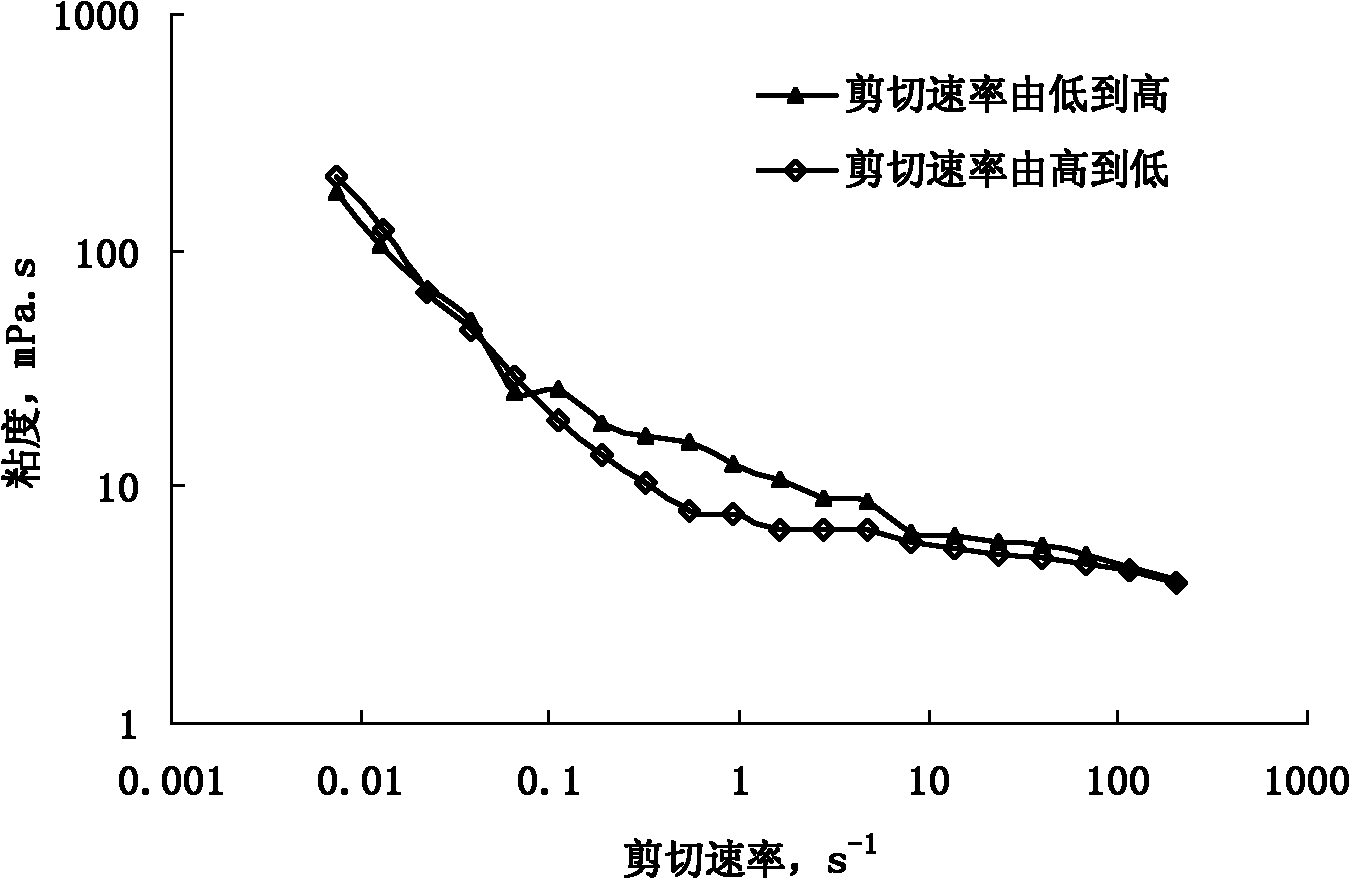

[0052] Example 2 The temperature-resistant, salt-resistant and shear-resistant performance of polymer oil displacement agent

[0053] Get a certain amount of WSAP01~WSAP04 synthesized in Example 1 to be formulated into a solution. The composition of the prepared water used is shown in Table 1 and Table 2. The test instrument used is a Brookfield DV-III viscometer, and the test condition is a constant shear rate of 7.34S -1 , the polymer solution concentration is 2000mg / L, the experimental results are as follows Figure 1~4 Shown: The new polymer oil displacement agent has good temperature resistance, calcium and magnesium ion resistance and good shear resistance.

[0054] Table 1 Injection water composition

[0055] Composition, mg / L

NaCl

CaCl 2

MgCl 2

Na 2 SO 4

NaHCO 3

KCl

total salinity

mixed water injection

6190.0

1579.0

1626.9

54.2

262.5

49.0

10069.8

[0056] Table 2 Compositi...

Embodiment 3

[0058] Injection performance of embodiment 3 polymer oil displacement agent

[0059] Get a certain amount of WSAP03, WSAP05, and WSAP06 synthesized in Example 1, prepare a solution of 5000 mg / L with injection water, then dilute with injection water into a solution with a concentration of 2500 mg / L. Inject the polymer solution into a sand filling pipe with a length of 50.0 cm and a diameter of 0.8 cm with a pressure measuring point in the middle to investigate the injectability of the polymer solution and the ability to establish a resistance coefficient and a residual resistance coefficient. See the experimental results Figure 5-7 and shown in Table 3. From Figure 5-7 It can be seen from the figure that in the highly permeable porous medium, during the injection process of 2500mg / L WSAP03, WSAP05, WSAP06 polymer solutions, the pressure rises slowly and gradually stabilizes, showing good injectability and the ability to establish high flow resistance. After a large amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com