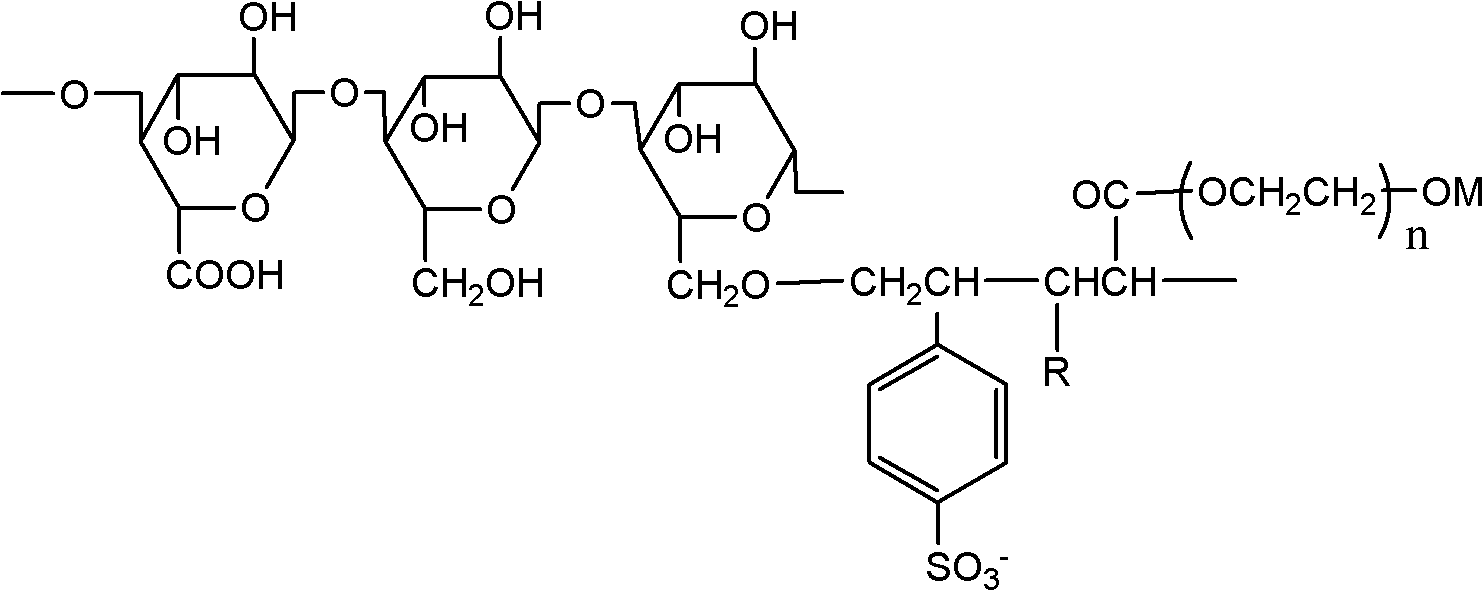

Starch graft copolymer coal-water slurry dispersants and preparation method thereof

A technology of starch grafting and dispersing agent, which is applied in the direction of liquid carbon-containing fuel, petroleum industry, fuel, etc., can solve the problems of high pulping cost and high price, and achieve easy biodegradation, reasonable structure and good universality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

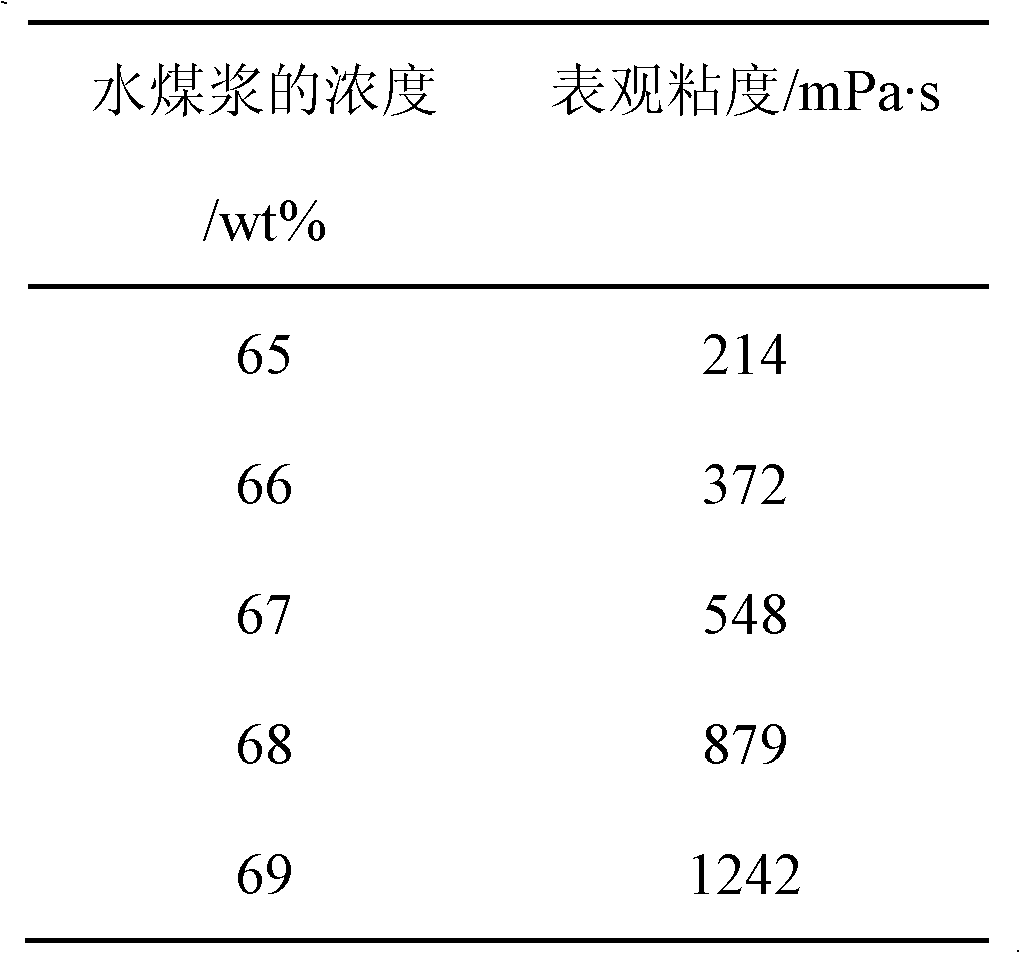

Embodiment 1

[0025] 1) Add 8% cornstarch, 8% potassium persulfate and 60% distilled water into a three-neck flask according to the mass fraction, heat up to 90°C with stirring, stir at constant temperature for 30min, then cool down to 80°C, and adjust the pH to 5-6 get a mixed solution;

[0026] 2) adding mass fraction to the mixed solution is 10% sodium styrene sulfonate and 10% acrylic acid-polyethylene glycol monoester, 4% redox initiator ferrous chloride-hydrogen peroxide, wherein the reducing agent is added once, and the oxidizing agent Add dropwise with a constant pressure dropping funnel, and incubate at 80°C for 2 hours;

[0027] 3) cooling the reactants to room temperature, and adjusting pH=7-9 with sodium hydroxide with a mass concentration of 10%-35% to obtain a starch graft coal water slurry dispersant;

[0028] For the coal water slurry with a concentration of 68% and a dispersant dosage of 0.4% of the slurry, there is no hard precipitation after standing for 15 days.

[002...

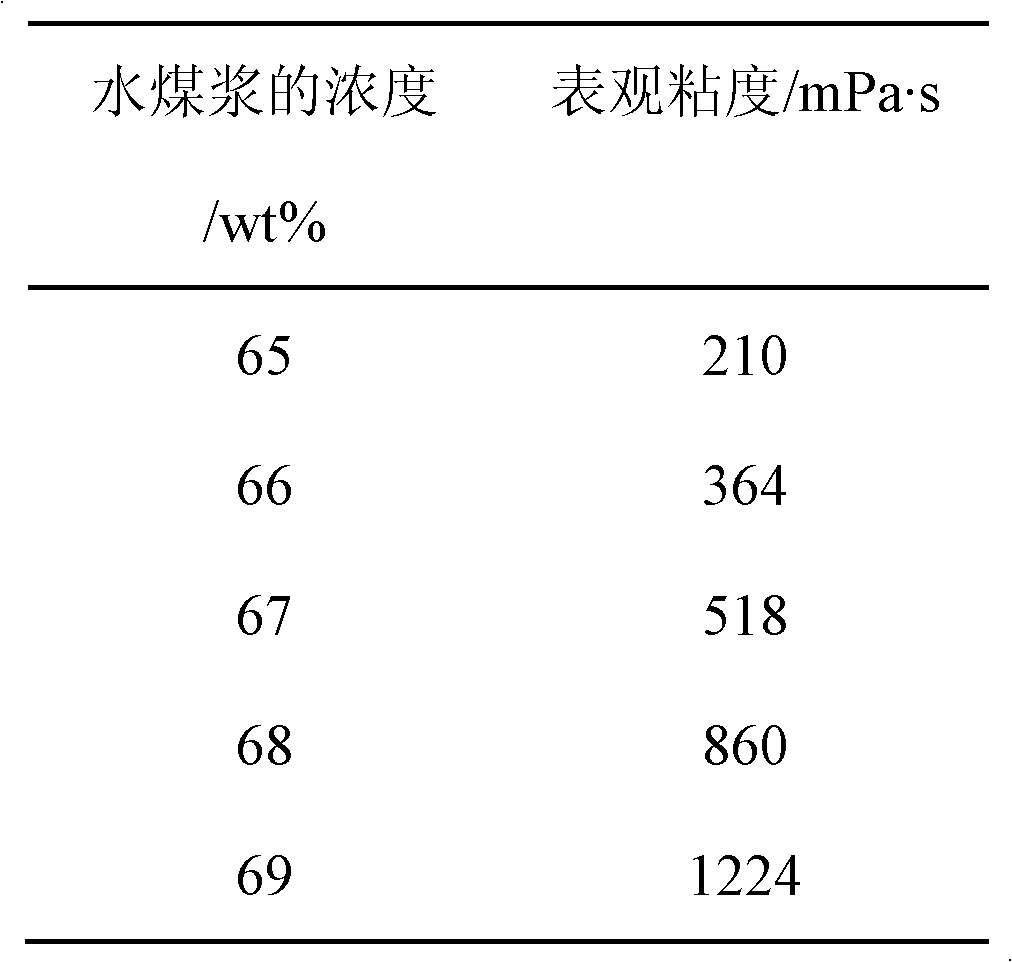

Embodiment 2

[0033] 1) Add 20% tapioca starch, 2% oxidant ammonium persulfate and 50% deionized water into a three-necked flask according to the mass fraction, heat up to 90°C under stirring, stir at constant temperature for 20min, then cool down to 75°C, and adjust the pH to 5-6 to obtain a mixed solution;

[0034] 2) adding mass fraction to the mixed solution is 15.7% sodium styrene sulfonate, 10% itaconic acid-polyethylene glycol monoester and 2% redox initiator ferrous sulfate-hydrogen peroxide, wherein the reducing agent is added once, The oxidizing agent is added dropwise with a constant pressure dropping funnel, and after 1-2 hours of reaction, 0.3% of molecular mass regulator dodecyl mercaptan is added, and the reaction is kept at 80°C for 3 hours;

[0035] 3) cooling the reactants to room temperature, and adjusting pH=7-9 with sodium hydroxide with a mass concentration of 10%-35% to obtain a starch graft coal water slurry dispersant;

[0036] For the coal water slurry with a conc...

Embodiment 3

[0041] 1) Add 15% cornstarch, 5% oxidant hydrogen peroxide and 46.9% distilled water into a three-neck flask according to the mass fraction, heat up to 90°C under stirring, stir at constant temperature for 50min, then cool down to 78°C, and adjust the pH to 5-6 to obtain mixture;

[0042] 2) adding mass fraction in mixed solution is 12% sodium styrene sulfonate and 18% maleic acid-polyethylene glycol monoester and 3% redox initiator sodium bisulfite-potassium persulfate, wherein reducing agent One-time addition, the oxidant is added dropwise with a constant pressure dropping funnel, after 1-2 hours of reaction, add 0.1% molecular weight regulator dodecyl mercaptan, and keep the reaction at 80°C for 5 hours;

[0043] 3) cooling the reactants to room temperature, and adjusting pH=7-9 with sodium hydroxide with a mass concentration of 10%-35% to obtain a starch graft coal water slurry dispersant;

[0044] For the coal water slurry with a concentration of 68% and a dispersant dos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com