High temperature-resisting cleaning CO2 foam fracturing liquid suitable for unconventional oil and gas reservoir development

A foam fracturing fluid and clean fracturing fluid technology are applied in the directions of drilling compositions, chemical instruments and methods, which can solve the problems of increasing the difficulty of fracturing construction, poor stability, and difficulty in flowback, and improve the fracturing performance. The effect of cracking production increase, good foaming performance, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Synthesis of thickener for foam fracturing fluid:

[0053] Add 30kg of acrylamide, 4kg of vinylpyrrolidone, 4kg of maleic acid, 5kg of 2-acrylamido-2-methylpropanesulfonic acid and 40.85kg of water into the reactor and mix well. Potassium regulates the pH value, and it is 8.02 to record the pH with a pH meter, add 8kg potassium chloride, pass circulating water to the reactor, add 0.15kg redox initiator potassium persulfate-sodium bisulfite at a temperature of 28 ° C, wherein The mass ratio of potassium persulfate to sodium bisulfite is 4:3, and the nitrogen flow is stopped, and the circulating water is stopped after 4 hours of reaction, and water vapor is passed in and kept at 95°C for 8 hours to obtain a colloidal product, and granulate the colloid , drying and crushing to obtain the thickener for the foam fracturing fluid.

[0054] Synthesis of viscosity boosters for foam fracturing fluids:

[0055] Add 10kg of ethylene glycol, 3kg of caustic soda and 57kg of water ...

Embodiment 2

[0060] High temperature resistant clean carbon dioxide foam fracturing fluid suitable for formation fracturing at 60°C:

[0061] Calculated by weight percentage, the anti-high temperature cleaning fracturing fluid part: 0.36% thickener for foam fracturing fluid, 0.2% pH regulator for foam fracturing fluid, 0.25% viscosity synergist for foam fracturing fluid, the balance for water;

[0062] (1) Rheology test: Test the temperature and shear resistance of high temperature resistant clean fracturing fluid.

[0063] Experimental equipment: Haake RS6000 rheometer, rotating cylinder test system, using rotor PZ38;

[0064] Test conditions: temperature 60°C, shear rate 170s -1 , Test time 60min.

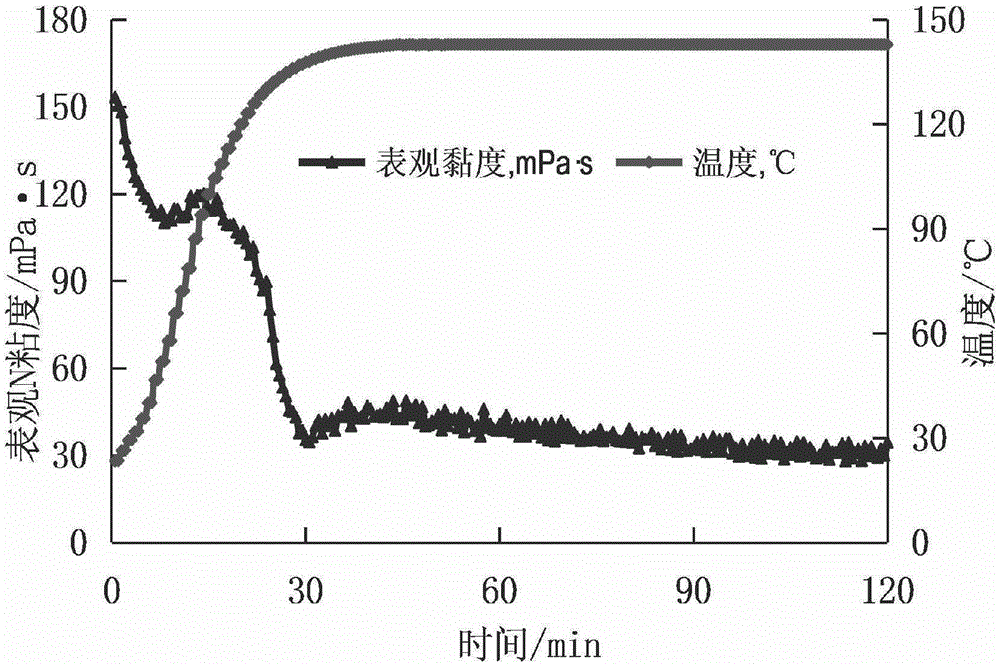

[0065] (2) Gel breaking test: the ammonium persulfate added to the high temperature resistant clean fracturing fluid is 0.045%;

[0066] (3) Add 0.045% ammonium persulfate to the high-temperature-resistant clean fracturing fluid on the sand mixer truck during on-site construction. The wei...

Embodiment 3

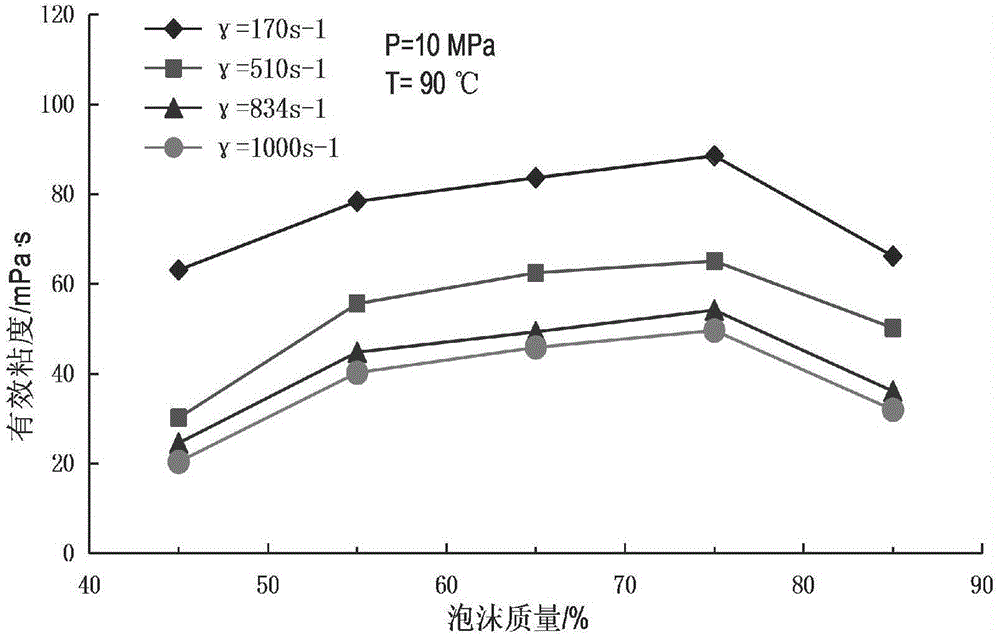

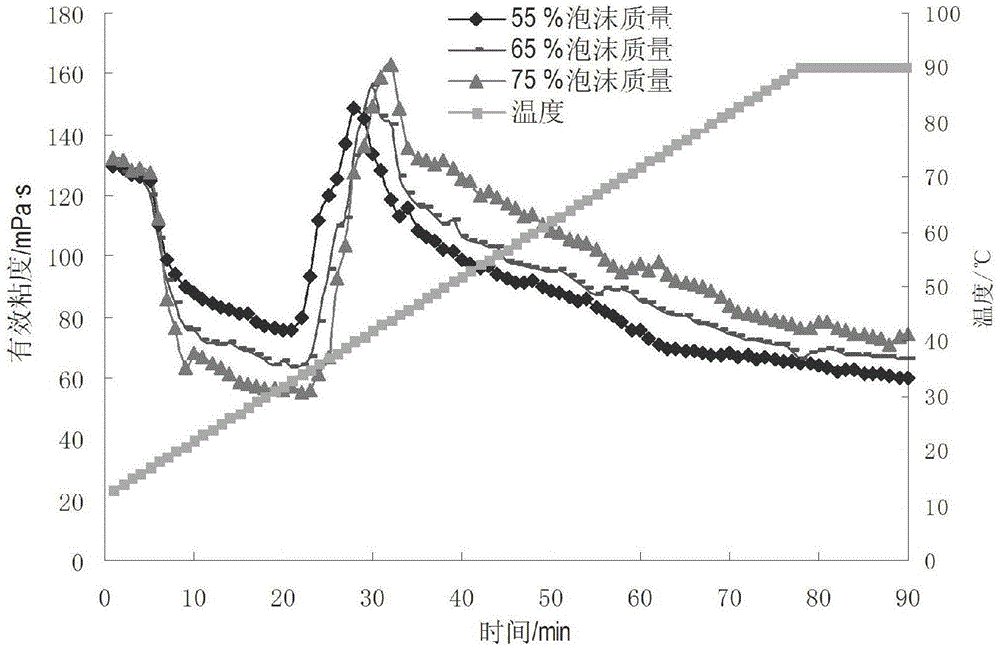

[0068] High temperature resistant clean carbon dioxide foam fracturing fluid suitable for formation fracturing at 90°C:

[0069] Calculated by weight percentage, the anti-high temperature cleaning fracturing fluid part: 0.44% thickener for foam fracturing fluid, 0.2% pH regulator for foam fracturing fluid, 0.35% viscosity synergist for foam fracturing fluid, the balance for water;

[0070] (1) Rheology test: Test the temperature and shear resistance of high temperature resistant clean fracturing fluid.

[0071] Experimental equipment: Haake RS6000 rheometer, rotating cylinder test system, using rotor PZ38;

[0072] Test conditions: temperature 90°C, shear rate 170s -1 , Test time 60min.

[0073] (2) Gel breaking test: the ammonium persulfate added to the high temperature resistant clean fracturing fluid is 0.035%;

[0074] (3) Add 0.035% ammonium persulfate to the high-temperature-resistant clean fracturing fluid on the sand mixer truck during on-site construction. The wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com