Lithium ion battery flame-retardant material for energy storage as well as preparation method and application thereof

A technology for lithium-ion batteries and flame-retardant materials, which is applied in the field of flame-retardant materials for lithium-ion batteries for energy storage and its preparation, can solve the problems of poor dispersion of flame retardants, poor dispersion of flame retardants, and poor flame retardant performance. Achieve stable product performance, good mixing and plasticizing ability, and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The flame-retardant material for lithium-ion batteries for energy storage in this embodiment is composed of polymeric phosphate, aluminum hydroxide, magnesium hydroxide, naphthenic oil, silane coupling agent A-174, polypropylene (model: t30s) by mass ratio 25:18:6:10:1.5:100 blended. The particle size of aluminum hydroxide is 5-10 μm, and the particle size of magnesium hydroxide is 5-10 μm.

Embodiment 2

[0037] The flame-retardant material for lithium-ion batteries for energy storage in this embodiment is composed of polymeric phosphate, aluminum hydroxide, magnesium hydroxide, naphthenic oil, silane coupling agent A-174, polypropylene (model: t30s) by mass ratio 10:30:15:5:3:100 blended. Among them, the particle size of aluminum hydroxide is 5-10 μm, and the particle size of magnesium hydroxide is 5-10 μm.

Embodiment 3

[0039] The flame-retardant material for lithium-ion batteries for energy storage in this embodiment is composed of polymeric phosphate, aluminum hydroxide, magnesium hydroxide, naphthenic oil, silane coupling agent A-174, polypropylene (model: t30s) by mass ratio 40:10:30:20:0.5:100 blended. Among them, the particle size of aluminum hydroxide is 5-10 μm, and the particle size of magnesium hydroxide is 5-10 μm.

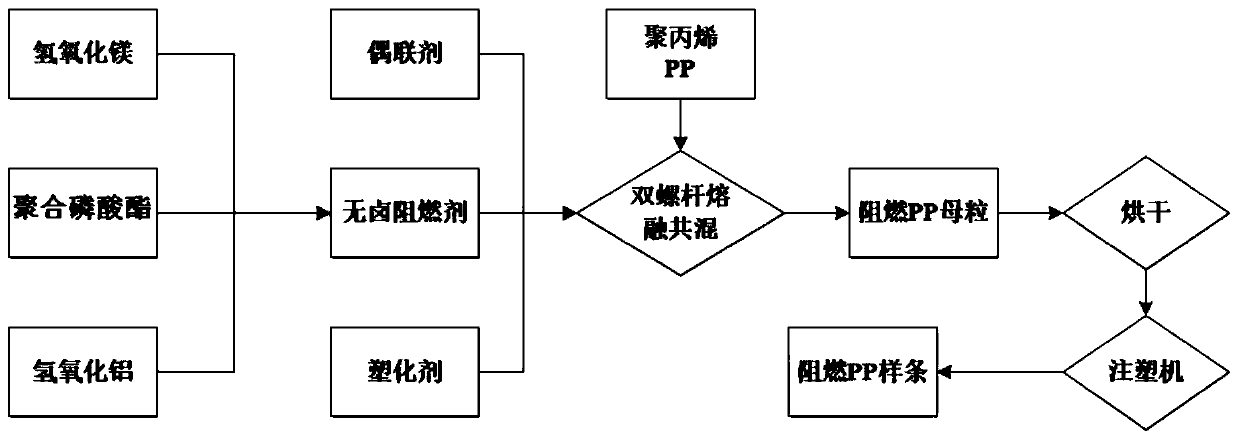

[0040] Two, the specific embodiment of the preparation method of the halogen-free flame-retardant polypropylene material of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com