Modified polymethyl methacrylate, optical thin film material, preparation method of optical thin film material and polaroid

A technology of polymethyl methacrylate and optical film, which is applied in the direction of optics, optical components, polarizing components, etc., can solve the problems of inability to meet high temperature resistance, negative refractive index, poor high temperature resistance, etc., and achieve a solution to the retardation value Higher, promoting compatibility, and solving the effect of poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of this modified PMMA comprises the steps:

[0026] Step S101: dissolving polymethyl methacrylate in an organic solvent and controlling the solid content between 5% and 15% to form a first mixed solution.

[0027] In the embodiment of the present invention, the polymethyl methacrylate raw material is a resin material with good transparency. Preferably, the aforementioned polymethyl methacrylate is a copolymerized polymethyl methacrylate with an average molecular weight of 70,000-130,000. The interior of the copolymerized polymethyl methacrylate includes, but is not limited to, an alicyclic structure, a heterocyclic structure, or a structure containing an aromatic group in a constituent unit. For example, the grade of copolymerized PMMA can be R100 from Nippon Denki Chemical Co., Ltd.

[0028] Step S102: Under an anhydrous and oxygen-free environment, phenol or phenol homologues and an organic solvent are stirred evenly in an ice-water bath to ob...

Embodiment 1

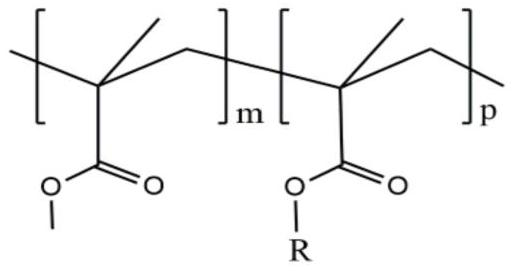

[0045] The modified PMMA that present embodiment provides, the structural formula of its polymer is as follows:

[0046]

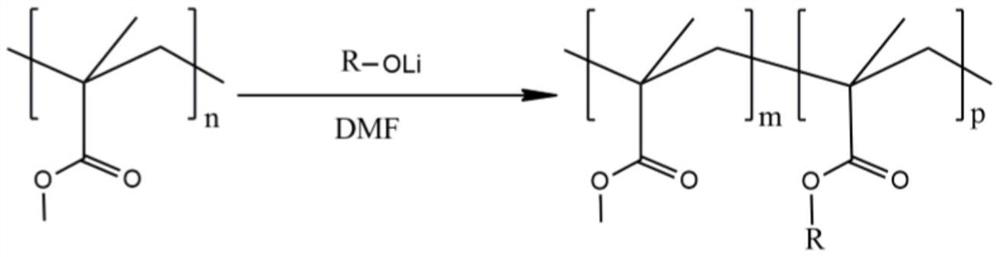

[0047] The preparation reaction equation of its modified PMMA is as follows:

[0048]

[0049] Take by weighing 5 parts of PMMA resin in molar weight, be dissolved in the organic solvent DMF, be made into PMMA-DMF organic solution; into a solution with a mass fraction of 10%, and stir evenly in an ice-water bath; when stirring, alternately vacuumize and vent nitrogen in the three-necked bottle to ensure that the inside of the three-necked bottle is in an anhydrous and oxygen-free environment; Inject 2 parts (molar amount) of lithium diisopropylamide (LDA); after stirring for 60 minutes, pour the PMMA-DMF organic solution into the three-necked bottle; the three-necked bottle is in an anhydrous and oxygen-free environment; remove the ice-water bath, and Continue to stir the mixed solvent in the bottle for 30 minutes, raise the reaction temperature to ...

Embodiment 2

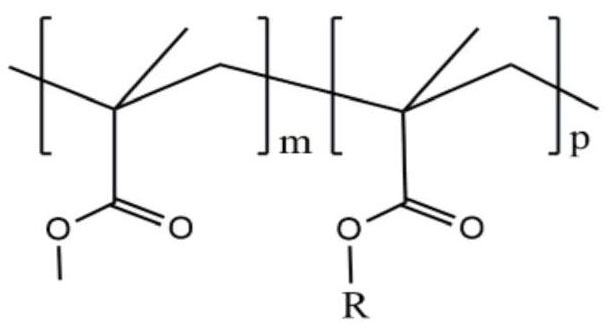

[0053] The modified PMMA that present embodiment provides, the structural formula of its polymer is as follows:

[0054]

[0055] The preparation reaction equation of its modified PMMA is as follows:

[0056]

[0057] Take by weighing 2.5 parts of PMMA resin in molar weight, be dissolved in the organic solvent DMF, be made into PMMA-DMF organic solution; into a solution with a mass fraction of 10%, and stir evenly in an ice-water bath; when stirring, alternately vacuumize and vent nitrogen in the three-necked bottle to ensure that the inside of the three-necked bottle is in an anhydrous and oxygen-free environment; Inject 1 part (molar amount) of lithium diisopropylamide (LDA); after stirring for 30 minutes, pour the PMMA-DMF organic solution into the three-necked bottle; the three-necked bottle is in an anhydrous and oxygen-free environment; remove the ice-water bath, and Continue to stir the mixed solvent in the bottle for 60 minutes, increase the reaction temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com