Theanine extraction process

An extraction process, theanine technology, applied in the separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problems of reduced adsorption performance, poor reproducibility of resin materials, difficult industrial realization, etc., achieving good regeneration performance and easy industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

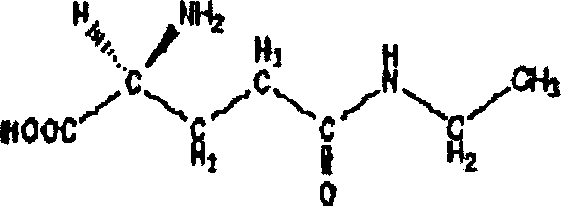

Image

Examples

Embodiment 1

[0021] 1) Chitosan flocculation and impurity removal: the residual liquid after extracting tea polyphenols from tea leaves, adjust the pH of the solution to 3.0 with hydrochloric acid, add chitosan at a weight ratio of 20:1 to the solids in the residual liquid at 25°C, and chitosan Dissolve the sugar with 1% acetic acid solution to make 2% chitosan solution, flocculate under low-speed stirring for 1 hour, filter and separate, remove the flocculent precipitate, and obtain the flocculation clear liquid;

[0022] 2) Adsorption and removal of pigments and macromolecular substances: take the flocculation clear liquid, add non-polar macroporous adsorption resin with 10% weight of soluble matter in the clear liquid, stir for 5 minutes, filter and remove the resin to obtain a nearly colorless and transparent adsorption clear liquid;

[0023] 3) Cationic exchange resin adsorption: After the cationic resin 732 is replaced by hydrogen form, balance with pH 3.0, 0.1mol / l citric acid and di...

Embodiment 2

[0030] 1) Chitosan flocculation and impurity removal: the residual liquid after extracting tea polyphenols from tea leaves, adjust the pH of the solution to 3.5 with hydrochloric acid, add chitosan at a weight ratio of 10:1 to the solids in the residual liquid at 35°C, chitosan Dissolve sugar with 2% acetic acid solution first to make 0.5% chitosan solution, flocculate under low-speed stirring for 2 hours, filter and separate, remove flocculent precipitate, and obtain flocculation clear liquid;

[0031] 2) Adsorption and removal of pigments and macromolecular substances: take the flocculation clear liquid, add non-polar macroporous adsorption resin with 20% of the weight of soluble matter in the clear liquid, stir for 10 minutes, filter and remove the resin to obtain a nearly colorless and transparent adsorption clear liquid;

[0032] 3) Cationic exchange resin adsorption: After cationic resin WA-2 is replaced by hydrogen form, balance with pH 3.5, 0.1mol / l citric acid and diso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com