Quadruple-effect method for rectifying and recycling waste water containing DMF (dimethyl formamide)

A recovery method and waste water technology, applied in organic chemistry, carboxylic acid amide separation/purification, etc., can solve problems such as difficult operation of the system, difficulty in controlling the quality of finished products, and inability to fully utilize heat, so as to save energy and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

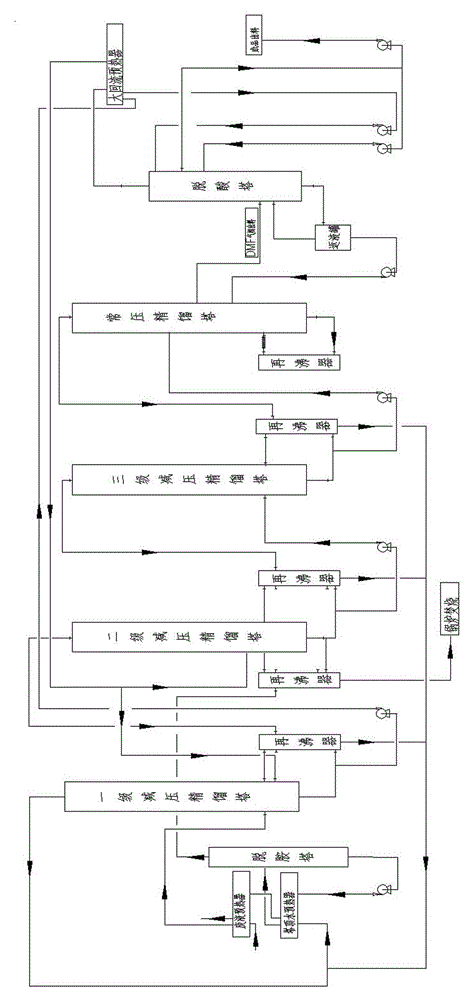

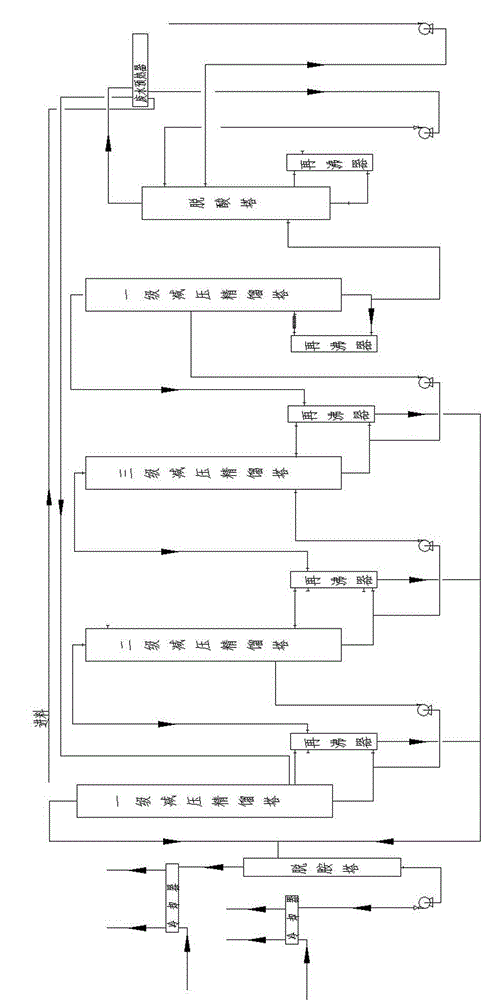

[0019] Such as figure 1 Shown, the present invention contains DMF waste water four-effect rectification recovery method and comprises: after the waste water containing DMF is preheated by waste water preheater, pass through one-level vacuum rectification tower successively (tower pressure is 9-12Kpa, and tower bottom temperature is 54-56℃ ), two-stage vacuum rectification tower (the top pressure is 23-27Kpa, the bottom temperature is 68-69℃), three-stage vacuum distillation tower (the top pressure is 44-49Kpa, the bottom temperature is 85- 89°C), the atmospheric rectification tower (100-103°C) and the deacidification tower are discharged, and the overhead steam of the second-stage vacuum rectification tower is preheated by the reboiler for the material of the first-stage vacuum rectification tower. The top steam of the three-stage vacuum rectification tower is preheated by the reboiler for the material of the two-stage vacuum rectification tower, and the top steam of the atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com