DMF recycling method

A recovery method and technology for recovering liquid, applied in the directions of organic chemistry, carboxylic acid amide separation/purification, etc., can solve the problems of environmental pollution, waste of production cost, etc., and achieve the effect of high recovery efficiency, reduction of production cost, and reduction of recovery cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

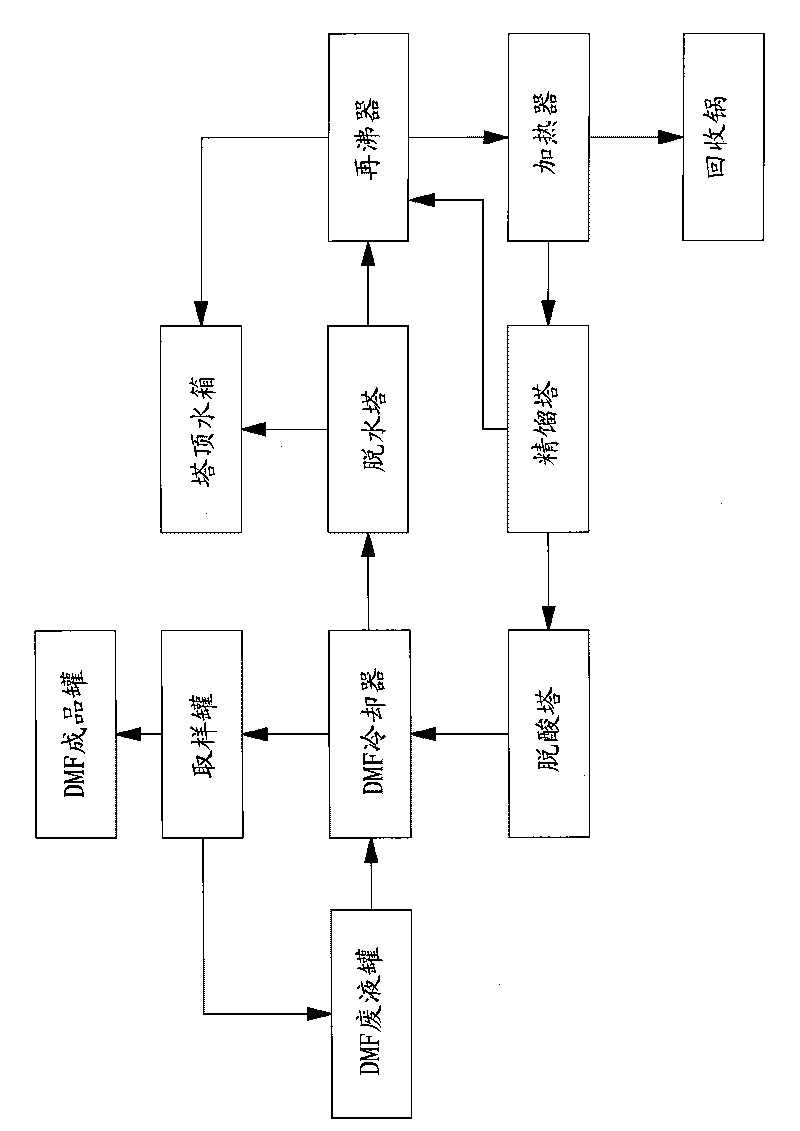

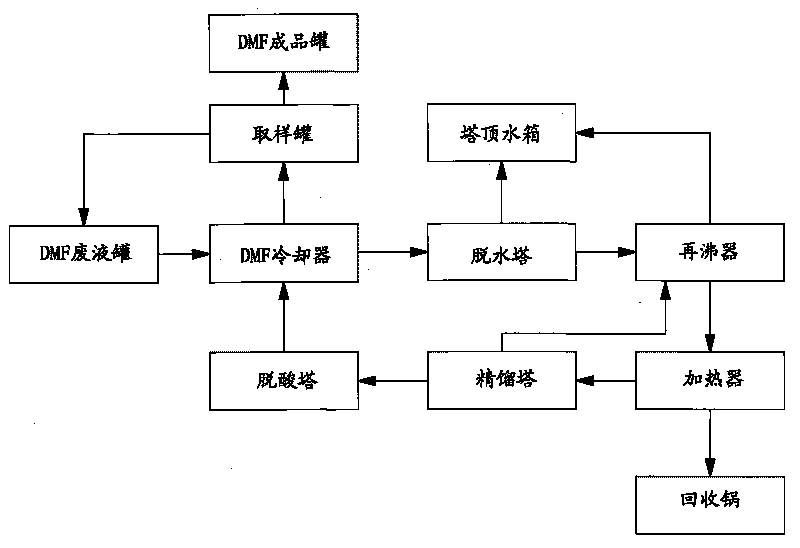

Image

Examples

Embodiment Construction

[0014] refer to figure 1 , the embodiment discloses a kind of DMF recycling method, comprises the steps:

[0015] 1), the dimethylformamide waste liquid (being DMF waste liquid) that produces in synthetic leather production process is uniformly transported to DMF waste liquid tank for storage, and described DMF waste liquid tank is the hollow structure with certain liquid volume, and tank The body is provided with a liquid inlet and a liquid outlet. When DMF is recovered, the DMF waste liquid is pumped from the waste liquid tank to the DMF cooler for preheating. The DMF cooler is a heat exchanger whose structure is similar to that of The known heat exchangers used for liquid heat exchange are similar. The temperature of the DMF waste liquid after preheating is 60±3°C. The heat medium used for preheating is the DMF recovery liquid after deacidification treatment in the subsequent recovery step. The DMF recovery The temperature of the liquid is between 120±5°C;

[0016] 2), pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com