Method for preparing capsicine monomer

A technology for capsaicin and dihydrocapsaicin, which is applied in the field of biomedicine, can solve the problems of complicated separation and purification process, unfavorable large-scale production and high cost, and achieves the effects of wide source of raw materials, low equipment requirements and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Measure 1L of capsicum essential oil in a 5L beaker, add 3L of 75% alcohol, stir and extract at 30°C for 2 hours, and after standing for 1 hour, the supernatant is obtained;

[0045] (2) the supernatant is decompressed and concentrated to remove alcohol to obtain a capsaicin concentrate, and the recovered alcohol is recycled;

[0046] (3) The concentrated solution is directly loaded on the column for adsorption, wherein the volume of the adsorption column is 377cm3 (the diameter of the adsorption column is 4cm, and the height is 30cm), and the flow rate of the upper column is 500ml / h;

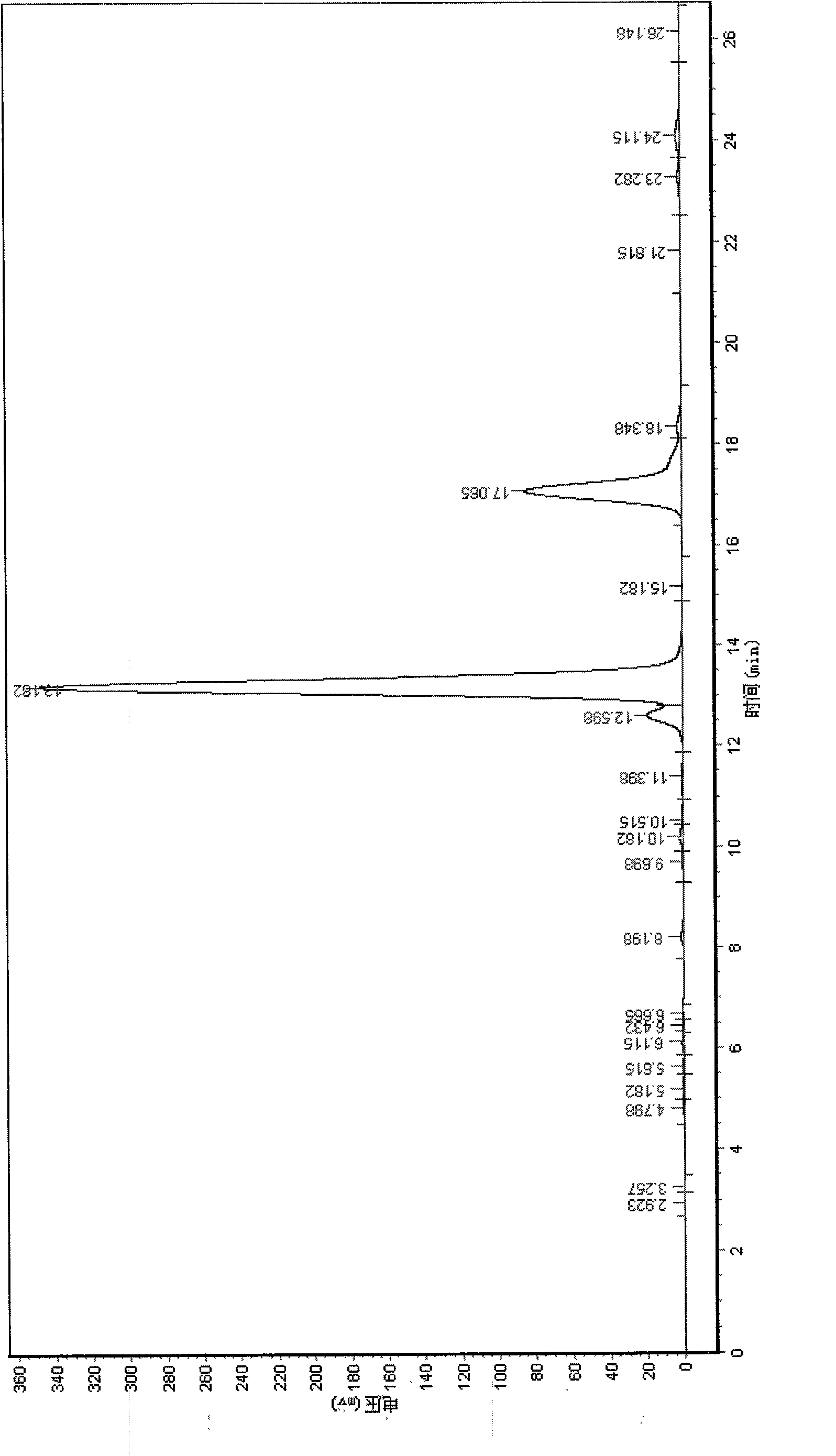

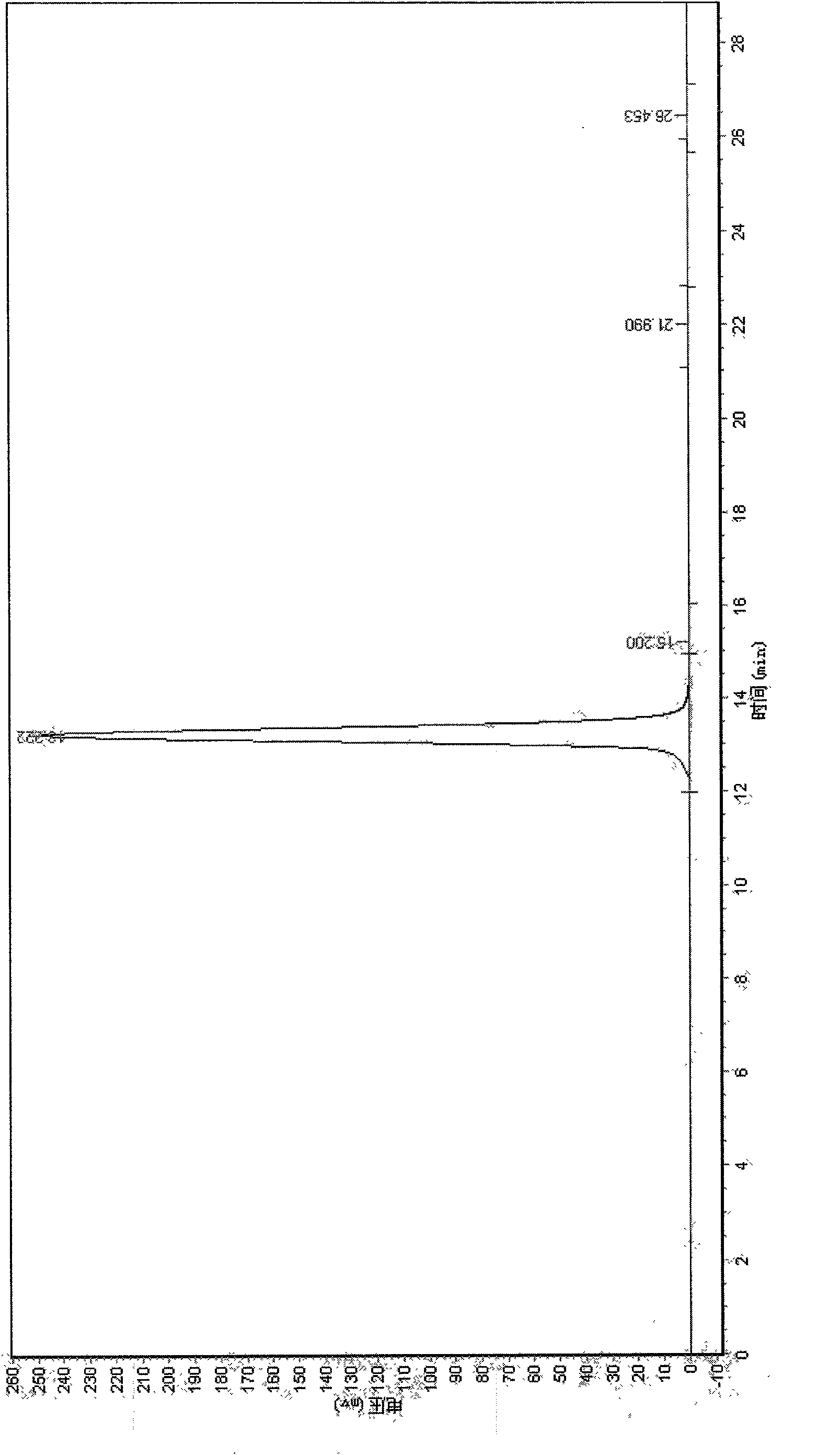

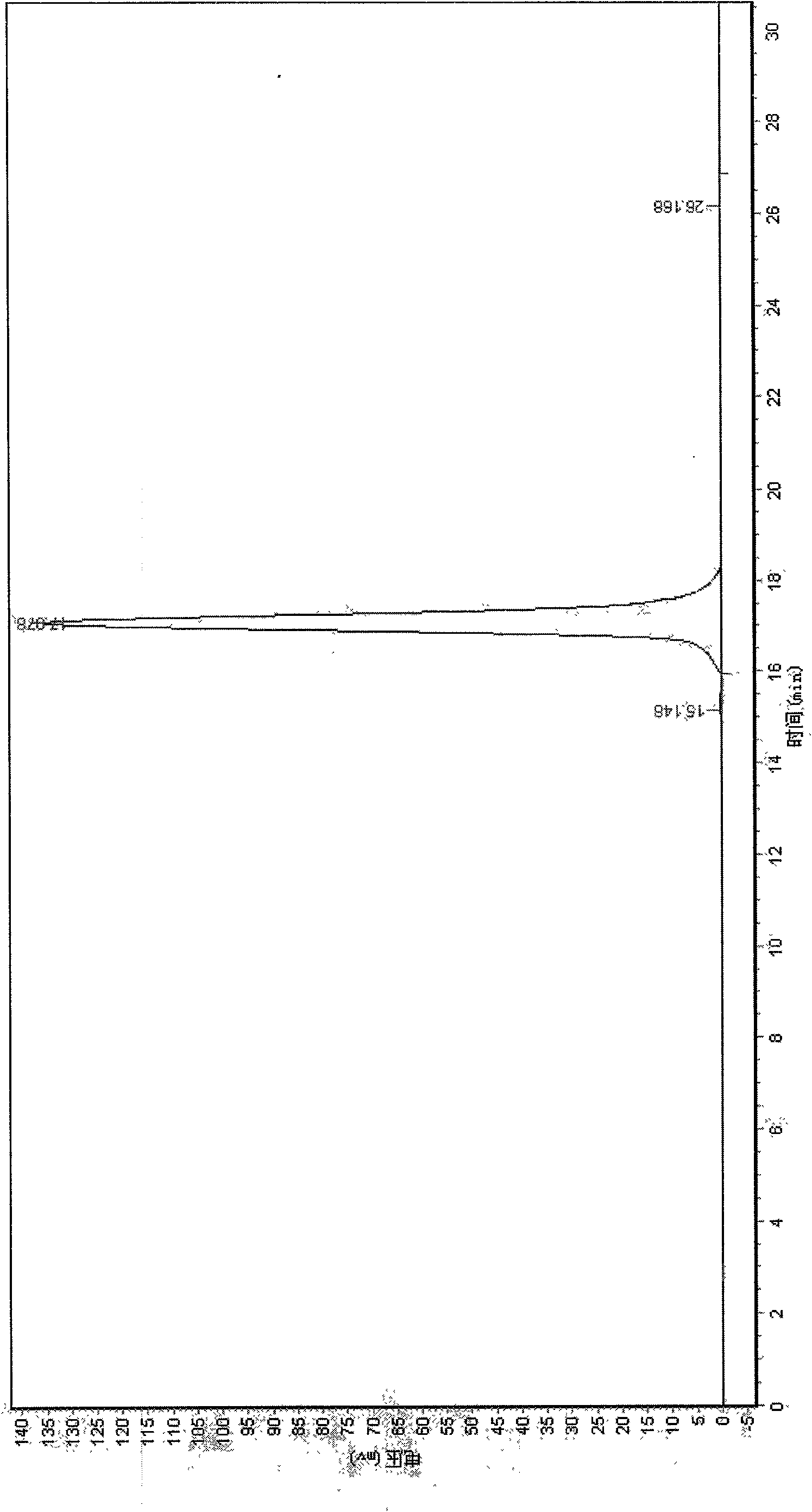

[0047] (4) When the product is completely absorbed, elute with 15% alcoholic water solution until the effluent is clear and colorless, so as to remove impurities and pigments; then use 1.2L 30% alcoholic water solution Carry out elution and collect the effluent, denoted as A; then elute with 1.2L 45% alcohol aqueous solution, collect the effluent, denote as B; finally use 1.2L 75% al...

Embodiment 2

[0056] (1) Weigh 1 kg of dry red chili powder in a 5L beaker, add 3L of 50% alcohol, stir and extract at 30°C for 8 hours, and after standing for 1 hour, obtain the supernatant;

[0057] (2) the supernatant is decompressed and concentrated to remove alcohol to obtain a capsaicin concentrate, and the recovered alcohol is recycled;

[0058] (3) The concentrated solution is directly adsorbed on the column, and the volume of the adsorption column is 377cm 3 (The diameter of the adsorption column is 4cm, the height is 30cm), and the flow rate of the upper column is 500ml / h;

[0059] (4) When the product is completely absorbed, elute with 20% alcoholic water solution until the effluent is clear and colorless, so as to remove impurities and pigments; then use 1.2L 35% alcoholic water solution Carry out elution and collect the effluent, denoted as A; then elute with 1.2L 50% alcohol aqueous solution, collect the effluent, denote as B; finally use 1.2L 70% alcohol aqueous solution for...

Embodiment 3

[0068] (1) Measure 100L chili essential oil in 1m 3 In a stainless steel extraction tank, add 300L 75% alcohol, stir and extract at 30°C for 3 hours, and after standing for 1 hour, the supernatant is obtained;

[0069] (2) the supernatant is decompressed and concentrated to remove alcohol to obtain a capsaicin concentrate, and the recovered alcohol is recycled;

[0070] (3) The concentrated solution is directly loaded onto the column for adsorption, wherein the volume of the adsorption column is 500L (the diameter of the adsorption column is 50cm, and the height is 2.55m), and the flow rate of the column is 800L / h;

[0071] (4) When the product is completely absorbed, elute with a 15% alcohol solution until the effluent is clear and colorless, so as to remove impurities and pigments; then use 1.5m 3 30% ethanol aqueous solution for elution, and collect the effluent, denoted as A; then use 1.5m 3 45% ethanol aqueous solution was used for eluting, and the effluent was collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com