Four-effect rectification system for synthesizing leather dimethyl formamide solution by wet method and recovery method

A technology of dimethylformamide and synthetic leather, applied in the field of separation and purification of dimethylformamide, to achieve great economic and social benefits, improve the level, and improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

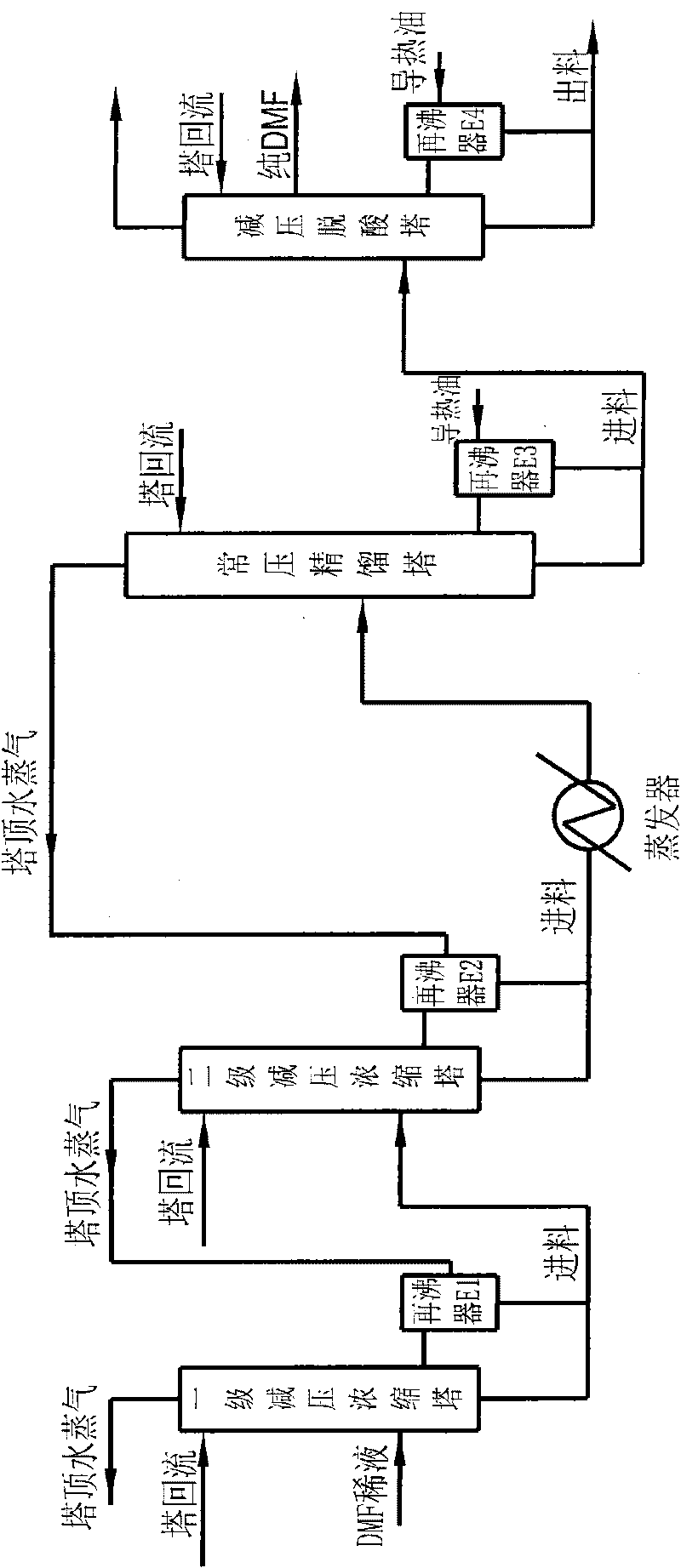

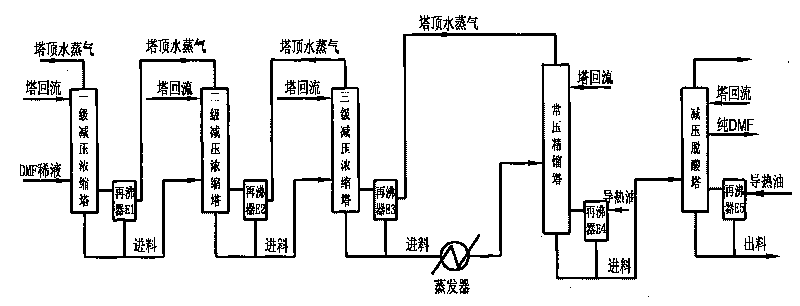

[0017] Three-effect DMF recovery process comparison example:

[0018] Fig. 1 shows the schematic diagram of traditional three-effect DMF recovery process, with the process of processing 12 tons per hour of DMF containing 18% (mass fraction) as an example, it includes feeding, preheating, decompression through two stages The concentration tower, the first-stage atmospheric distillation tower and the first-stage deacidification tower are concentrated, separated, and discharged to form a recovery process flow; it uses heat-conducting oil or low-pressure steam as the heat medium, and adopts the first-stage decompression concentration and the second-stage decompression Pressure concentration, atmospheric distillation, vacuum deacidification process. The above-mentioned recycling process adopts a recycling process, and the heat energy generated is recycled between the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com