Method for separating ammonia carbon in melamine tail gas

A technology for the separation of melamine and ammonia and carbon, which is applied in separation methods, preparation/separation of ammonia, and separation of dispersed particles. It can solve the problems of cumbersome separation steps, low product recovery rate, large energy and resource consumption, and achieve simplified separation. Steps, protect the environment, improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

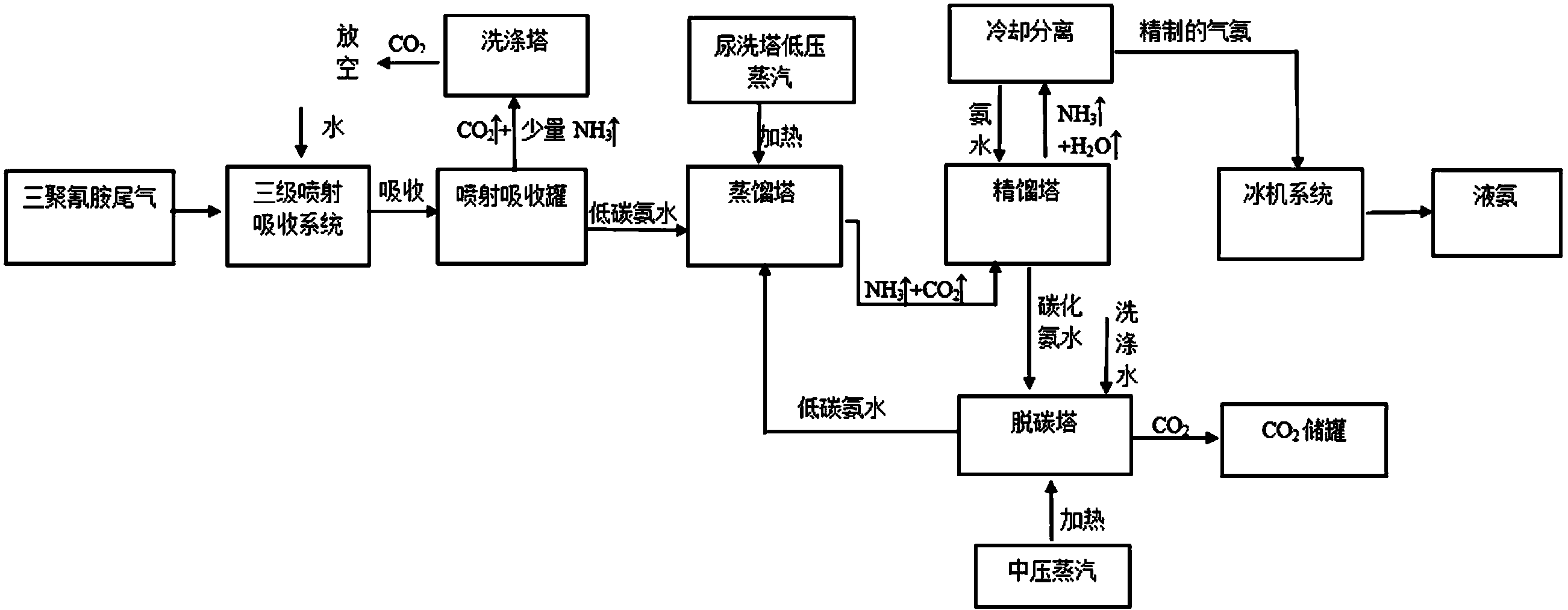

[0026] Refer to attached figure 2 :

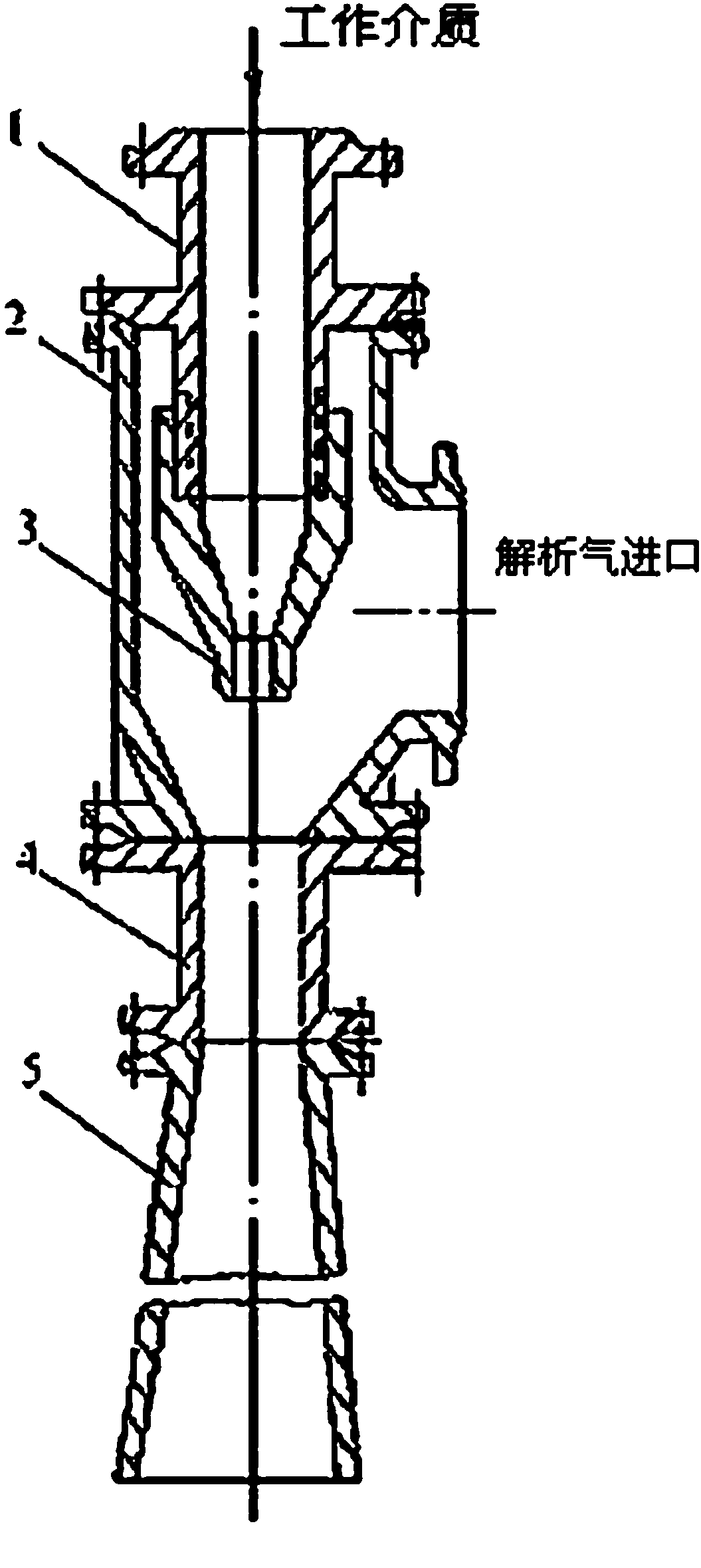

[0027] a. Absorption: The tail gas sent by the melamine plant with a temperature of 135-136°C is absorbed by adding water through the injector, such as figure 1 As shown, water enters the injector through 1 working medium inlet, and sprays down through 3 nozzles, and contacts and absorbs the melamine tail gas entering from the analytical gas inlet. After further mixing and absorbing through 4 mixing tubes and 5 diffusing tubes, 99% The above ammonia is absorbed to produce low-carbon ammonia water (ammonia: 12~13%, carbon dioxide: 5~6%) and stored in the spray absorption tank; the remaining carbon dioxide tail gas containing a small amount of ammonia is recovered through the scrubber to recover the ammonia in the tail gas , to reduce the ammonia in the tail gas to below 50ppm and vent it.

[0028] b. Distillation: Directly heat the ammonia water at 50-60°C from the spray absorption tank with low-pressure steam at 120-125°C and 0.2MPa. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com