Method for simultaneously separating three main components of bovine milk casein

A technology of cow's milk casein and main components, which is applied in the field of protein separation and preparation, can solve the problems of large consumption of chemical reagents, difficulty in realizing industrialization, and complicated separation process, so as to reduce the cost of reagents and equipment, and reduce the loss of monomers. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

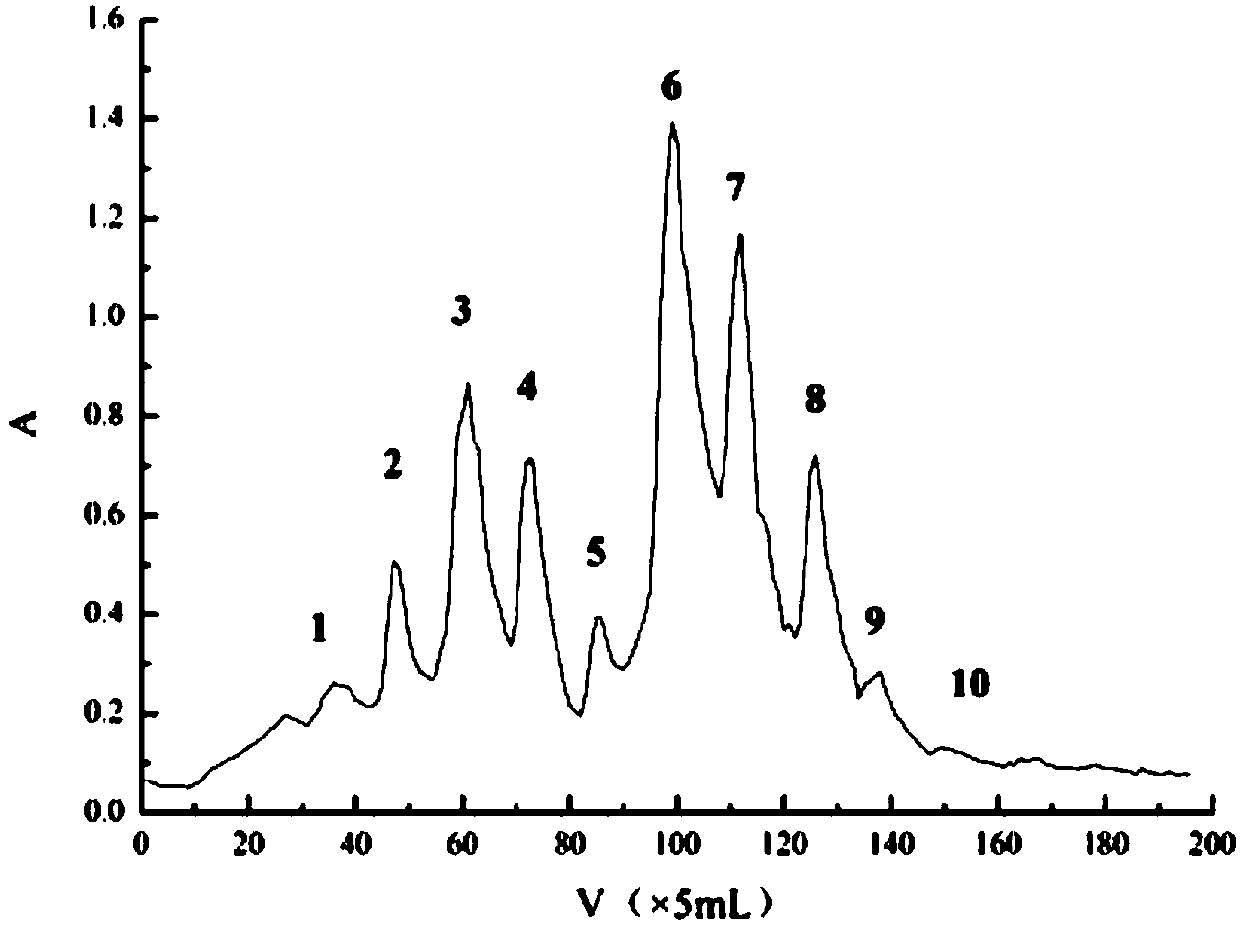

Embodiment 1

[0025] Weigh 1.0 g of acid-precipitated bovine milk casein, dissolve it in 20 mL of tris hydrochloric acid aqueous solution containing 3.3 mol / L urea and pH 8.5, add 2 μL of β-mercaptoethanol, deionized water, and magnetically stir until the protein is completely dissolved.

[0026] Weigh 40g of DEAE ion exchange resin, rinse with appropriate amount of distilled water to remove impurities; add 0.5mol / L NaOH to soak for 2h, wash with distilled water until neutral; then add 0.5mol / L HCl to soak for 2h, wash with distilled water until neutral. Pour the treated ion exchange resin into the chromatographic column and let it settle slowly.

[0027] Use a peristaltic pump to transport tris hydrochloride buffer solution (containing 3.3mol / L urea) at pH 8.5 to the top of the chromatography column at a flow rate of 1mL / min to balance the chromatography column; when the pH of the effluent The column is equilibrated when the pH of the equilibration buffer is the same.

[0028] The casein...

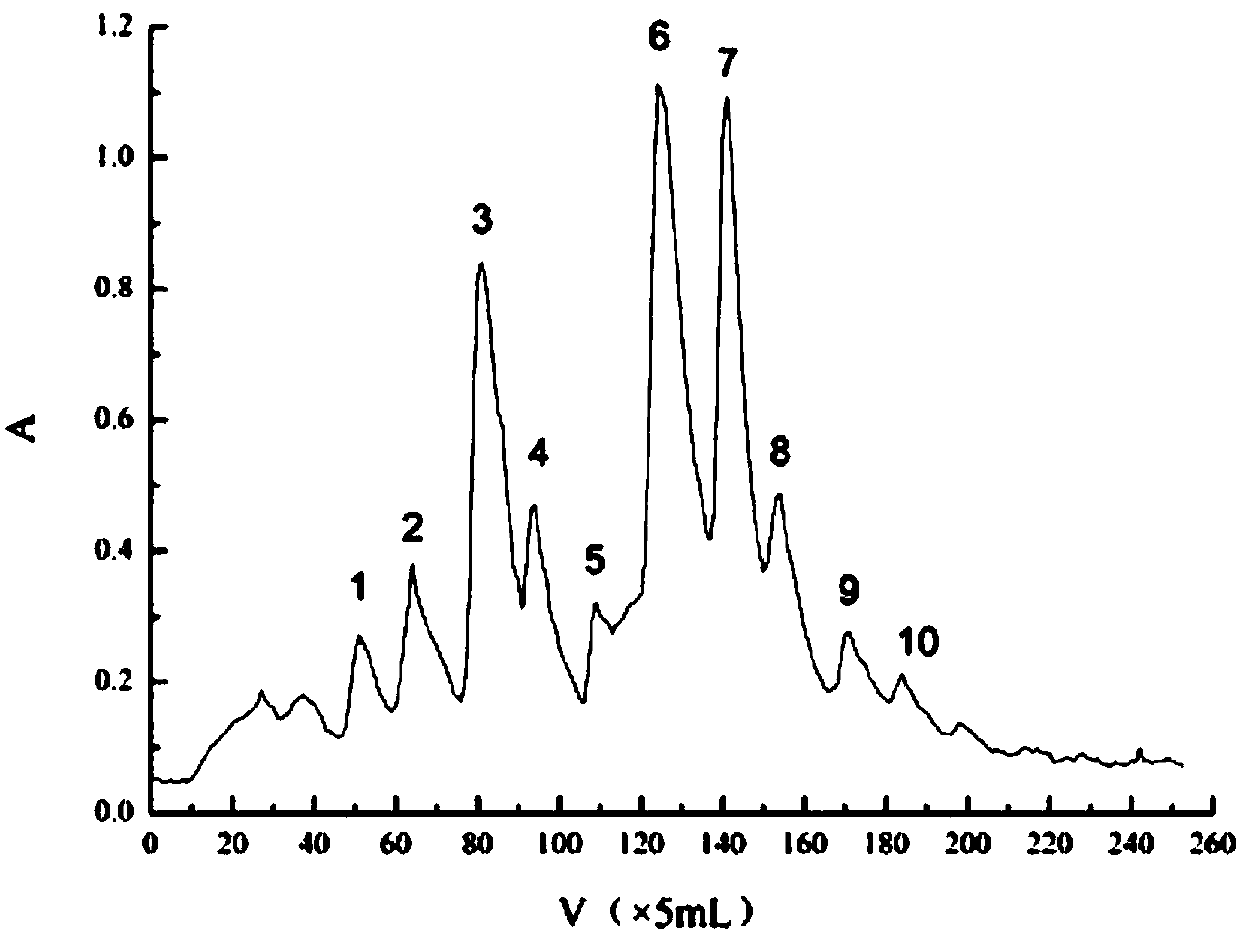

Embodiment 2

[0033] Weigh 1.0 g of acid-precipitated bovine milk casein, dissolve it in 50 mL of tris hydrochloric acid aqueous solution containing 3.3 mol / L urea, pH 8.5, add 2 μL of β-mercaptoethanol, deionized water, and magnetically stir until the protein is completely dissolved.

[0034] Weigh 70g of DEAE ion exchange resin, rinse with appropriate amount of distilled water to remove impurities; add 0.5mol / L NaOH to soak for 2h, wash with distilled water until neutral; then add 0.5mol / L HCl to soak for 2h, and wash with distilled water until neutral. Pour the treated ion exchange resin into the chromatographic column and let it settle slowly.

[0035] Use a peristaltic pump to transport tris hydrochloride buffer solution (containing 3.3mol / L urea) at pH 8.5 to the top of the chromatography column at a flow rate of 1mL / min to balance the chromatography column; when the pH of the effluent The column is equilibrated when the pH of the equilibration buffer is the same.

[0036] The casei...

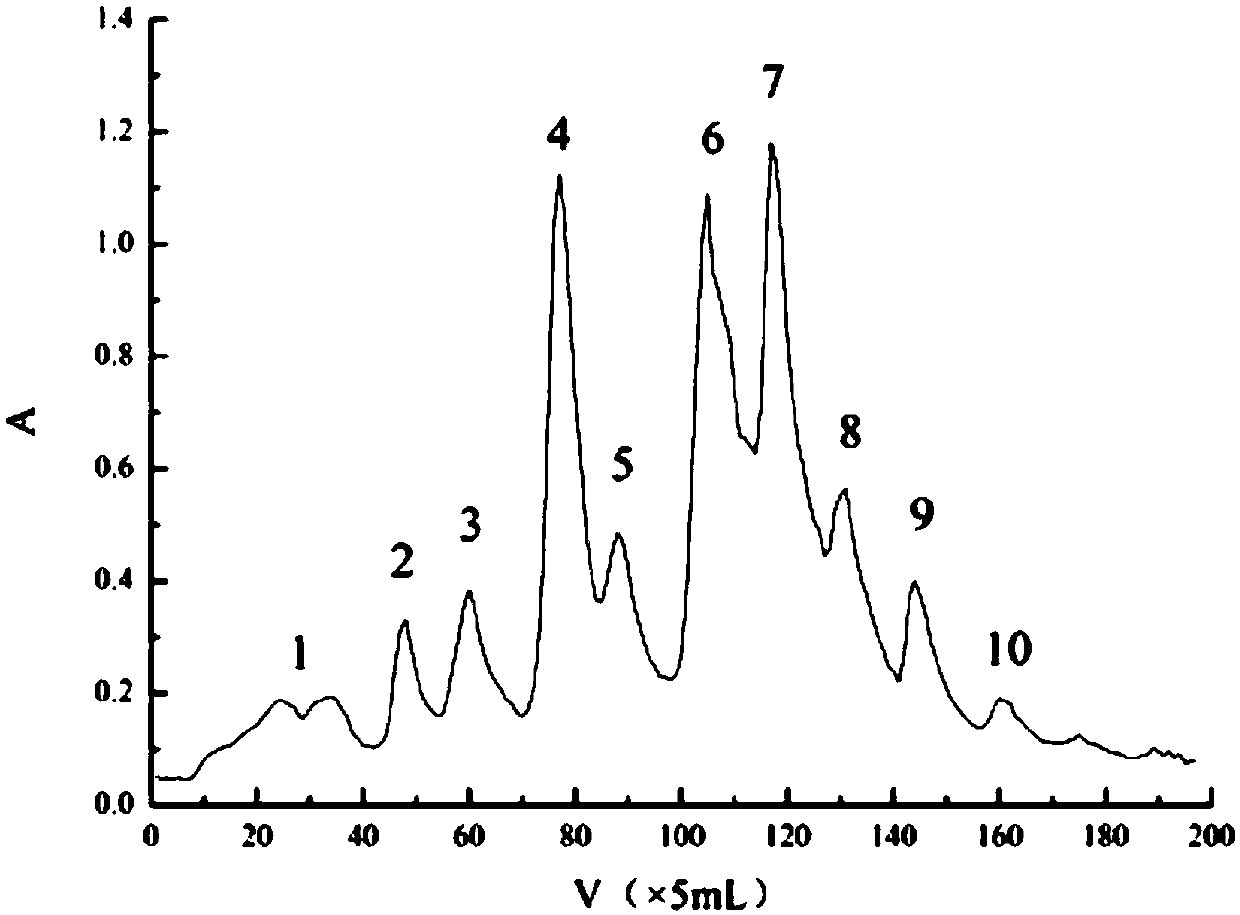

Embodiment 3

[0040] Weigh 1.0 g of acid-precipitated bovine milk casein, dissolve it in 30 mL of tris hydrochloric acid aqueous solution containing 3.3 mol / L urea, pH 8.5, add 2 μL of β-mercaptoethanol, deionized water, and magnetically stir until the protein is completely dissolved.

[0041] Weigh 50g of DEAE ion exchange resin, rinse with appropriate amount of distilled water to remove impurities; add 0.5mol / L NaOH to soak for 2h, wash with distilled water until neutral; then add 0.5mol / L HCl to soak for 2h, wash with distilled water until neutral. Pour the treated ion exchange resin into the chromatographic column and let it settle slowly.

[0042] Use a peristaltic pump to transport tris hydrochloride buffer solution (containing 3.3mol / L urea) at pH 8.5 to the top of the chromatography column at a flow rate of 1mL / min to balance the chromatography column; when the pH of the effluent The column is equilibrated when the pH of the equilibration buffer is the same.

[0043] The casein so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com