Production line of electrostatic spinning nanofiber membrane

A nanofiber film and electrospinning technology, which is applied in the directions of layered products, lamination devices, lamination auxiliary operations, etc., can solve problems such as production lines that do not form wide-width electrospinning nanofiber films, and achieve industrialization. The effect of preparation, easy operation and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with specific embodiments.

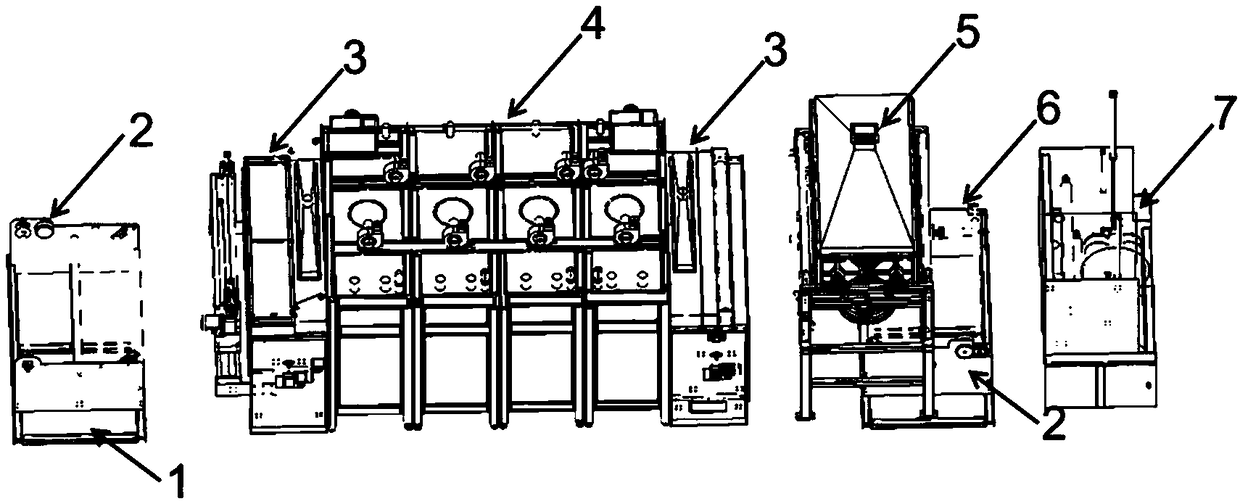

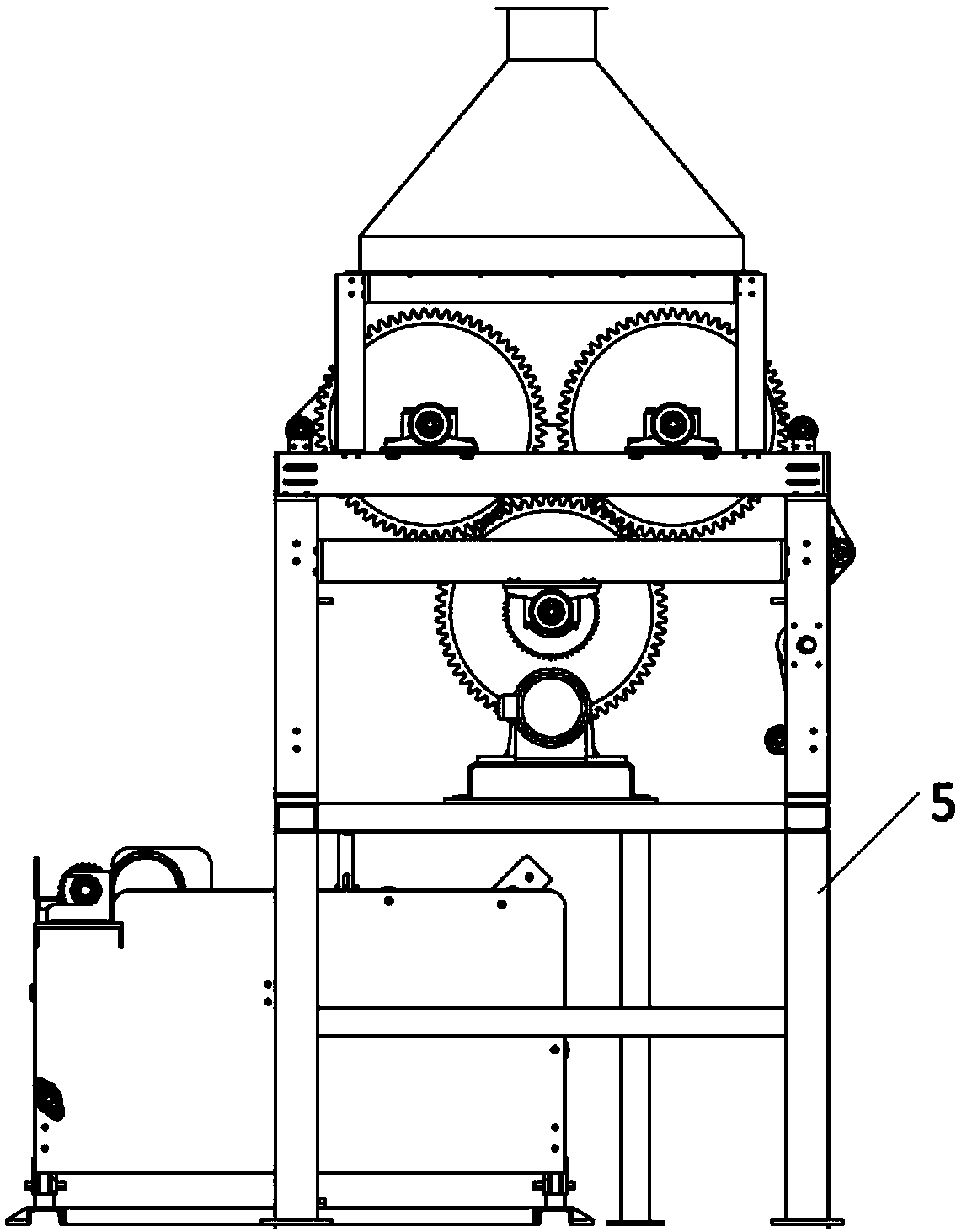

[0021] figure 1 This embodiment provides a schematic diagram of the electrospinning nanofiber membrane production line. The electrospinning nanofiber membrane production line consists of a base fabric unwinding device 1, a longitudinal tension control device 2, a transverse tension control device 3, and electrospinning The box body 4, the drying device 5, the protective layer base fabric unwinding device 6 and the winding device 7 are composed of components.

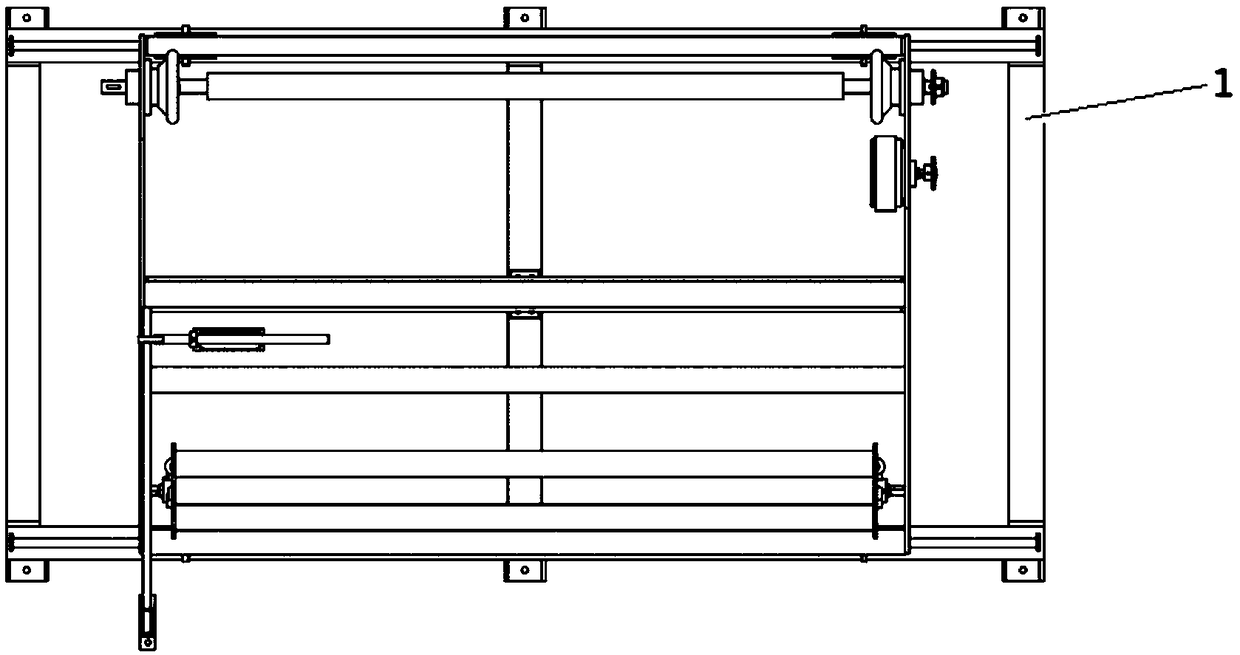

[0022] Combine figure 2 , The base fabric unwinding device 1 unwinds the non-woven base fabric and transports it to the electrostatic spinning box 4.

[0023] The longitudinal tension control device 2 and the transverse tension control device 3 can ensure that the non-woven base fabric in the electrospinning box 4 is evenly expanded in the vertical and horizontal directions within the working area of the electrospinning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com