Patents

Literature

82results about How to "Short separation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

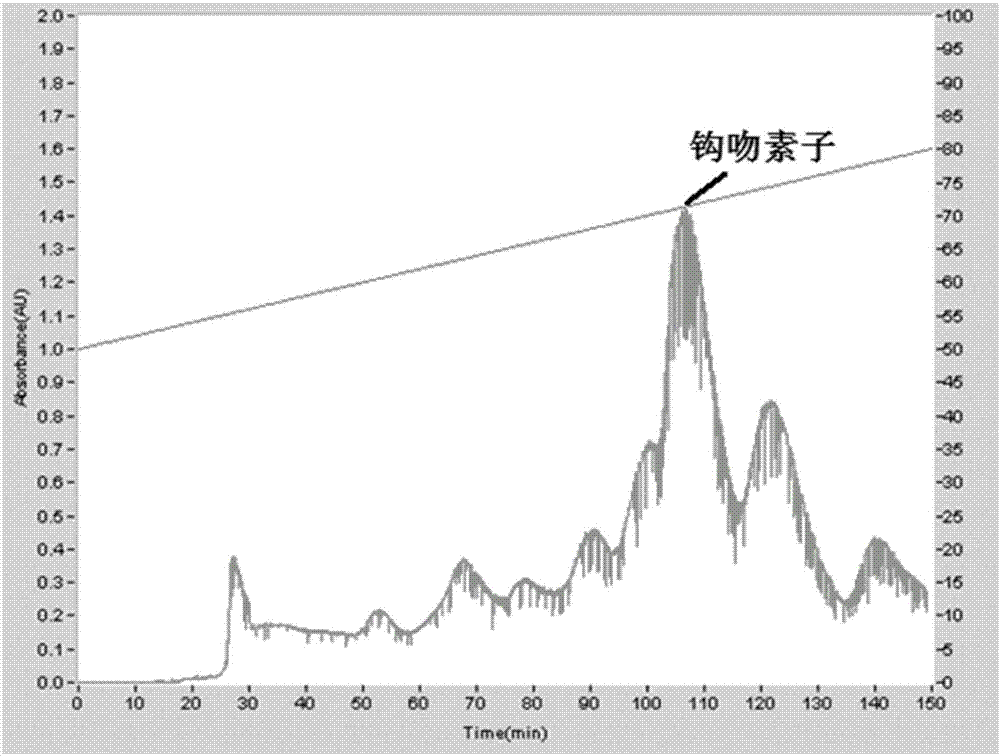

Method for separating and preparation of Gelsemium elegans alkaloid monomer by high speed counter current chromatography

ActiveCN101323618ASimple and fast operationShort separation cycleOrganic chemistrySolid sorbent liquid separationGelsemium elegansGelsemium

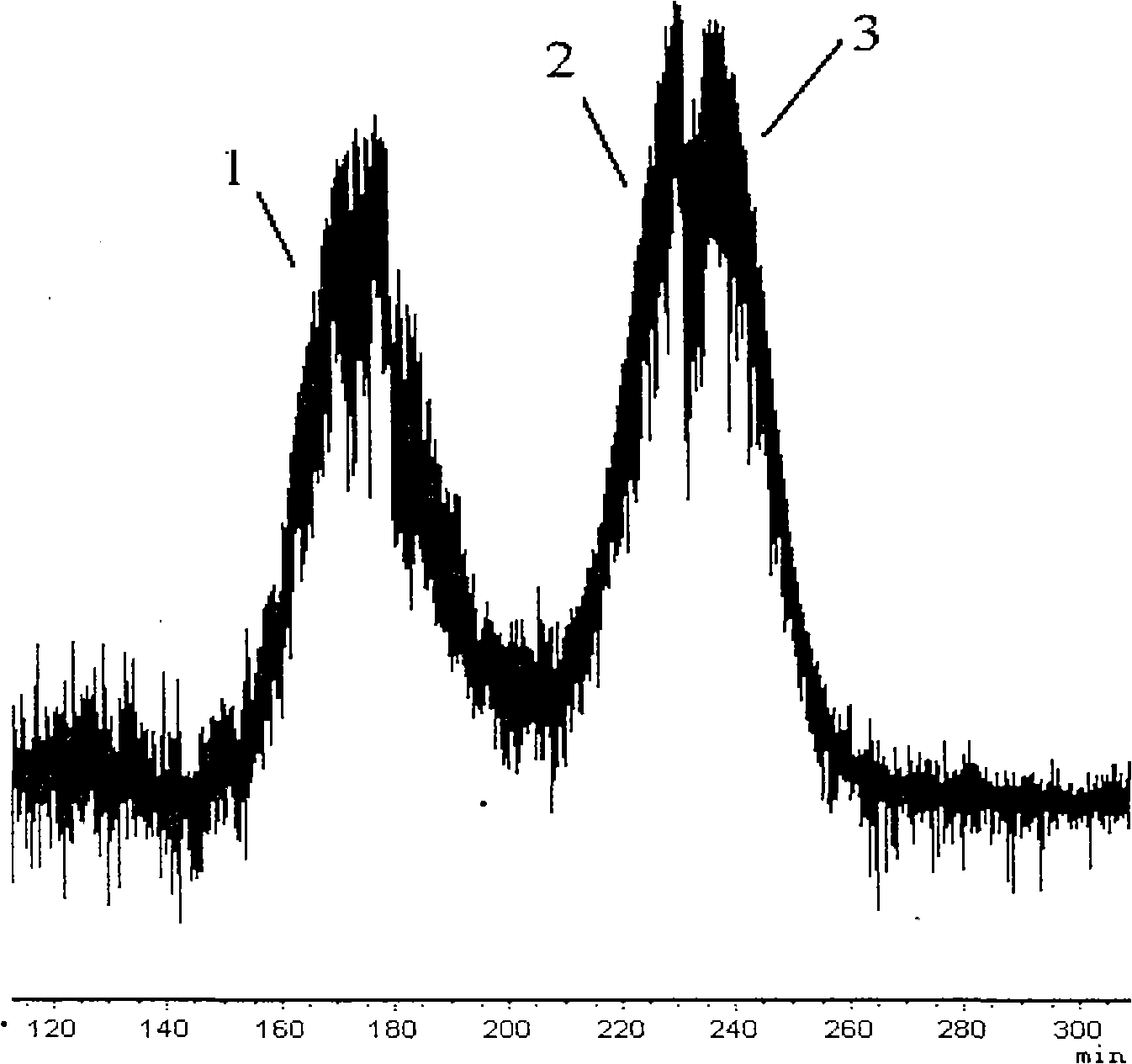

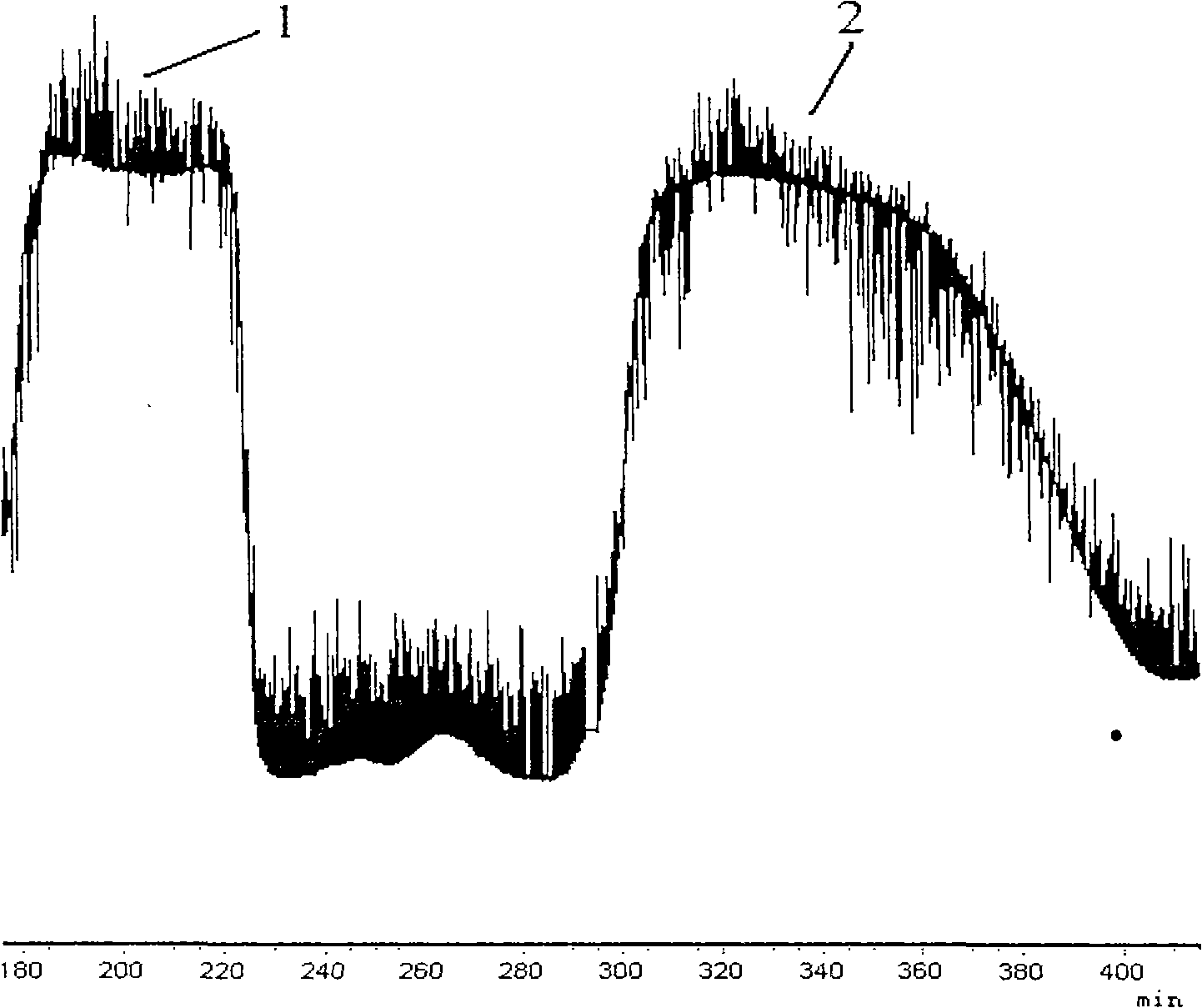

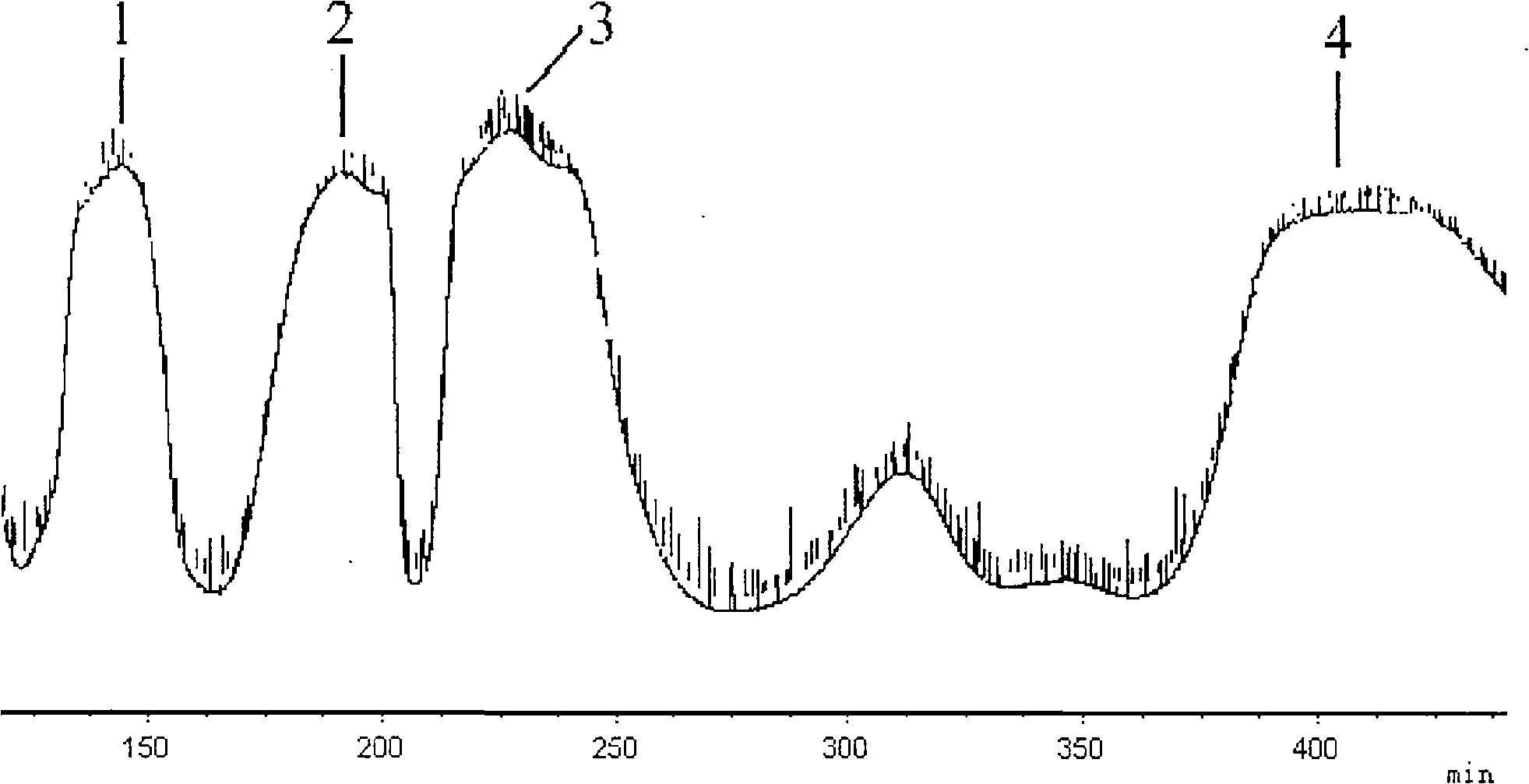

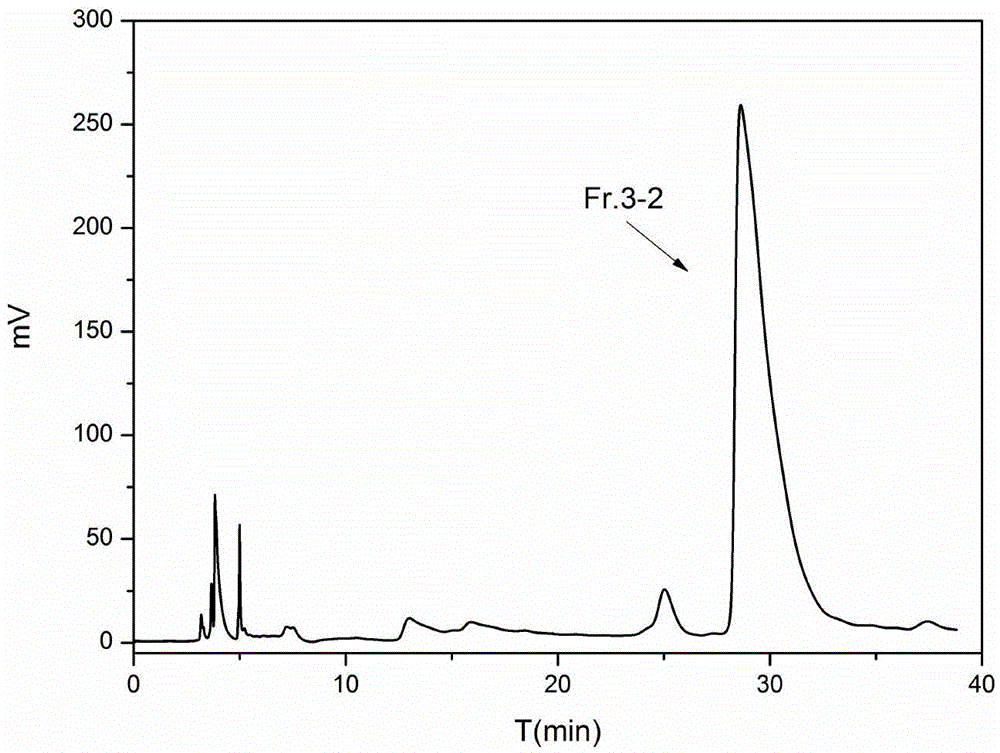

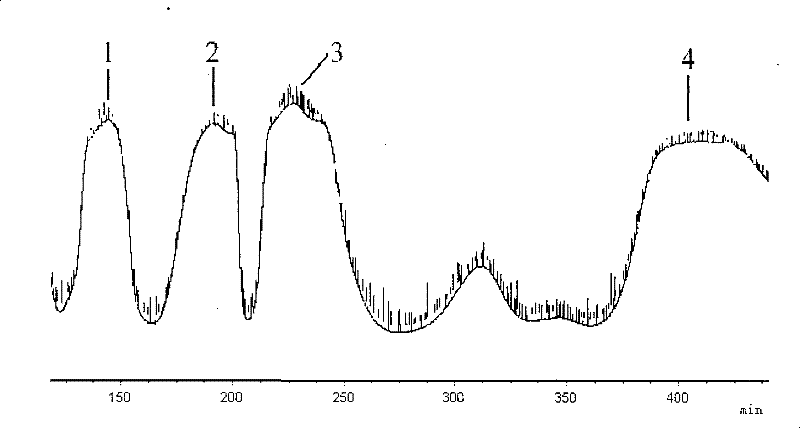

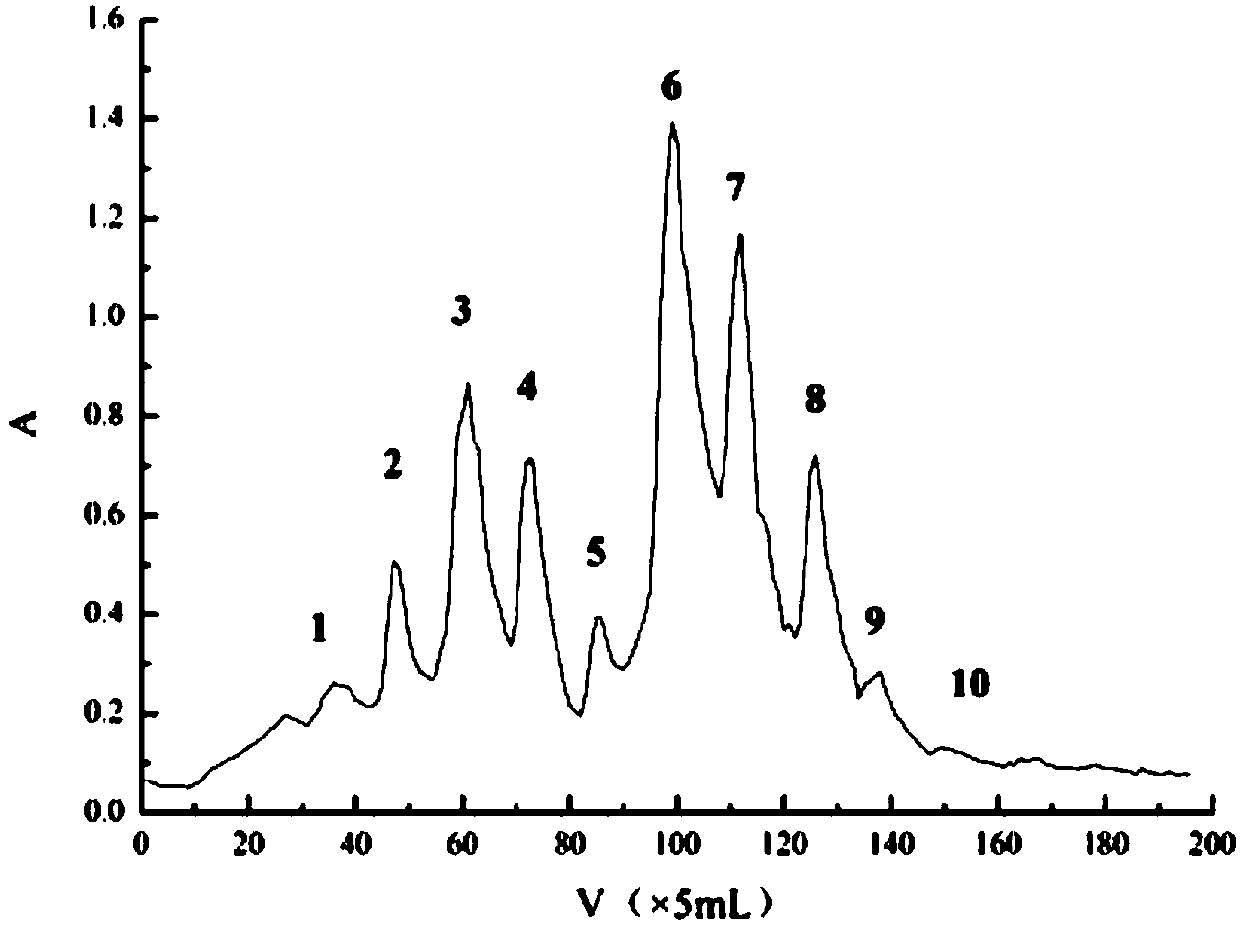

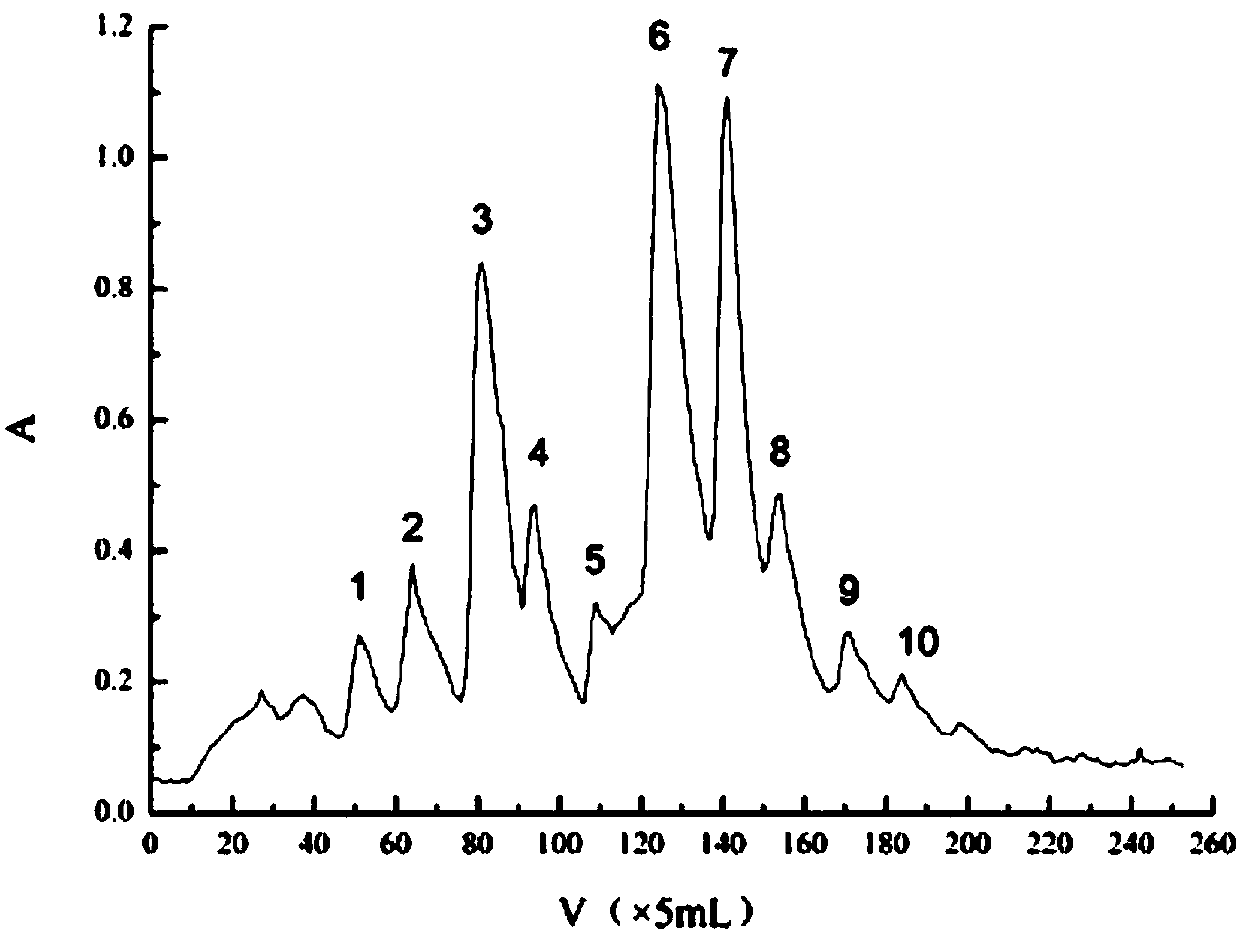

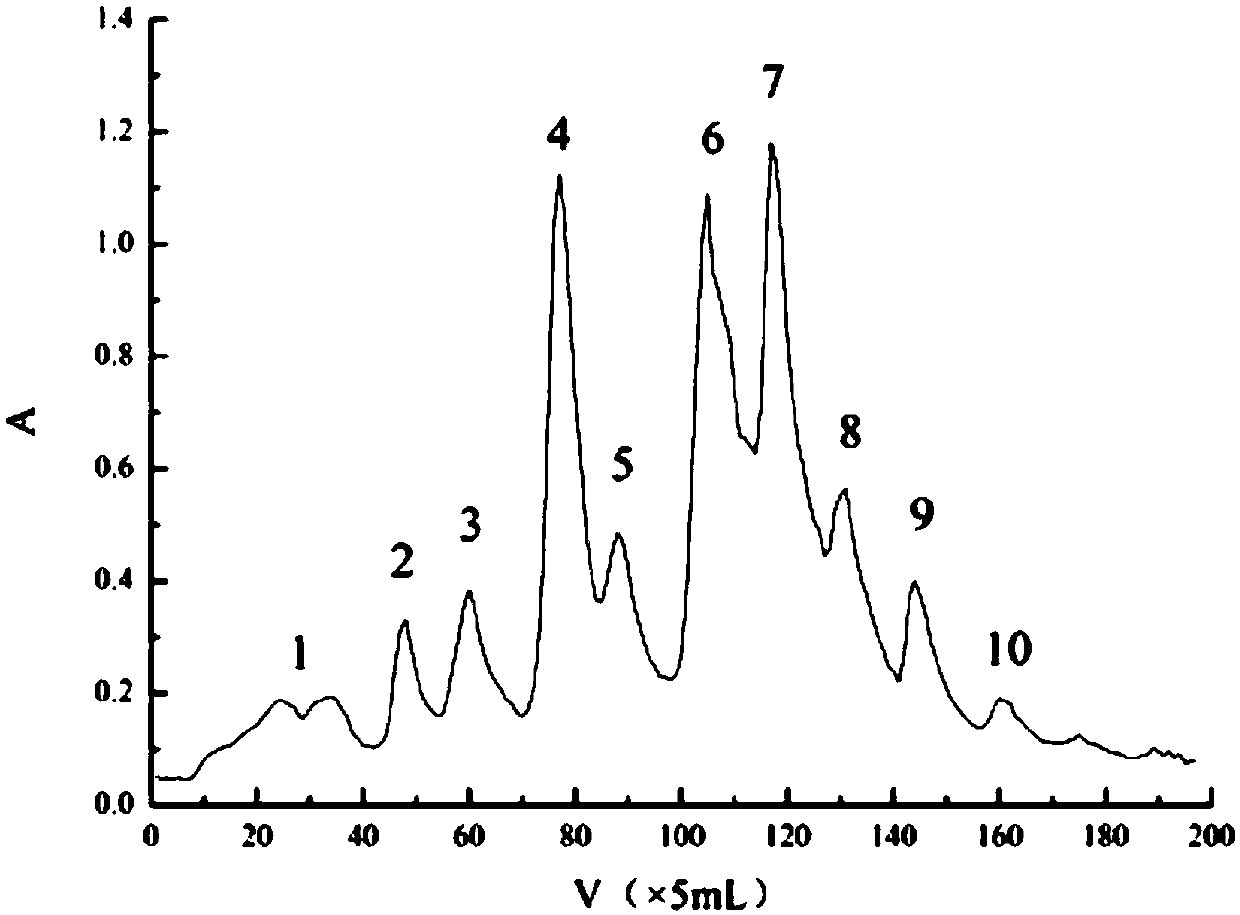

The invention discloses a method for separating and preparing a gelsemium alkaloid monomer from gelsemium by adopting high-speed counter current chromatography, which pertains to the separation method of medicinal plant monomers. The invention takes total alkaloids of gelsemium as a raw material and a high-speed counter current chromatograph as a separating device and the method comprises that a solvent system which is composed of stationary phase and mobile phase is prepared; the high-speed counter current chromatograph is filled with the stationary phase and then the mobile phase is pumped in and balanced; and then sampling is conducted by a sample valve; target components are collected according to the map of a detector or in combination of the detection methods of high efficiency liquid chromatography and thin layer chromatography, and distilled under reduced pressure and then recrystallized to obtain the gelsemium alkaloid monomer with high purity. By adjusting the specific proportional parameters of the solvent system, single or multiple target gelsemium alkaloid monomers can be separated by one step or step by step. The method is convenient and efficient, large in preparation amount, less in sample loss, good in separation effect and high in controllability and applicable to automatic production and the obtained gelsemium alkaloid monomer from separation has diverse pharmacological activities and application prospect to be prepared into medicines.

Owner:FUJIAN MEDICAL UNIV

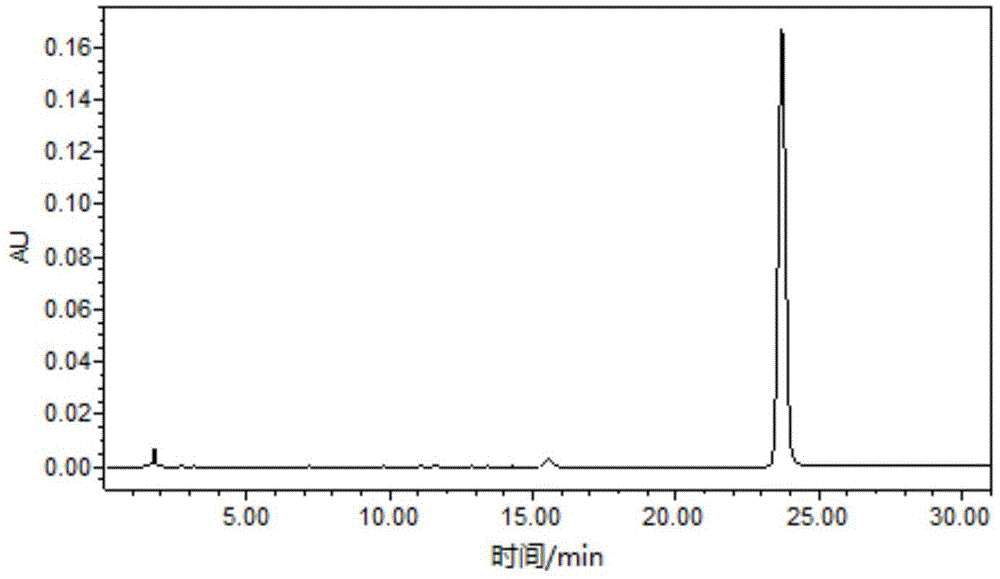

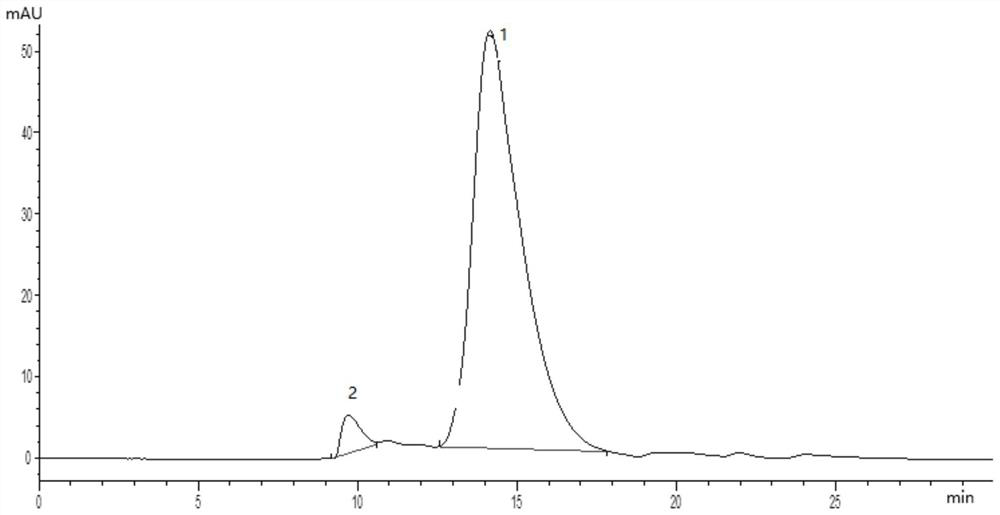

A method of separating and purifying quercetagetin from tagetes erecta

ActiveCN105693676AWide variety of sourcesHigh degree of automationOrganic chemistryFiltrationEvaporation

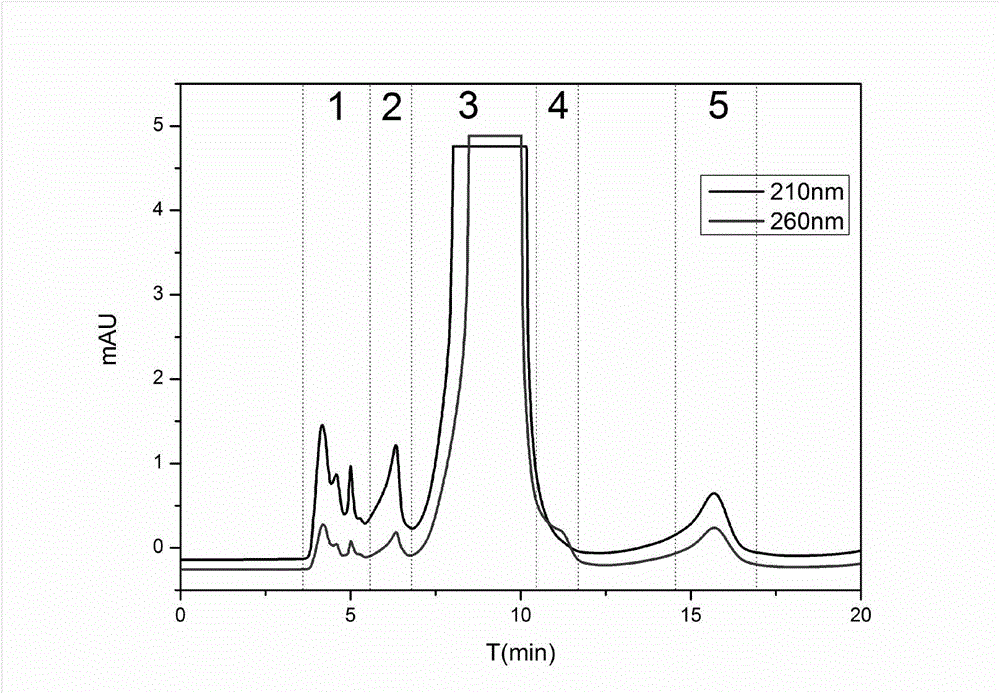

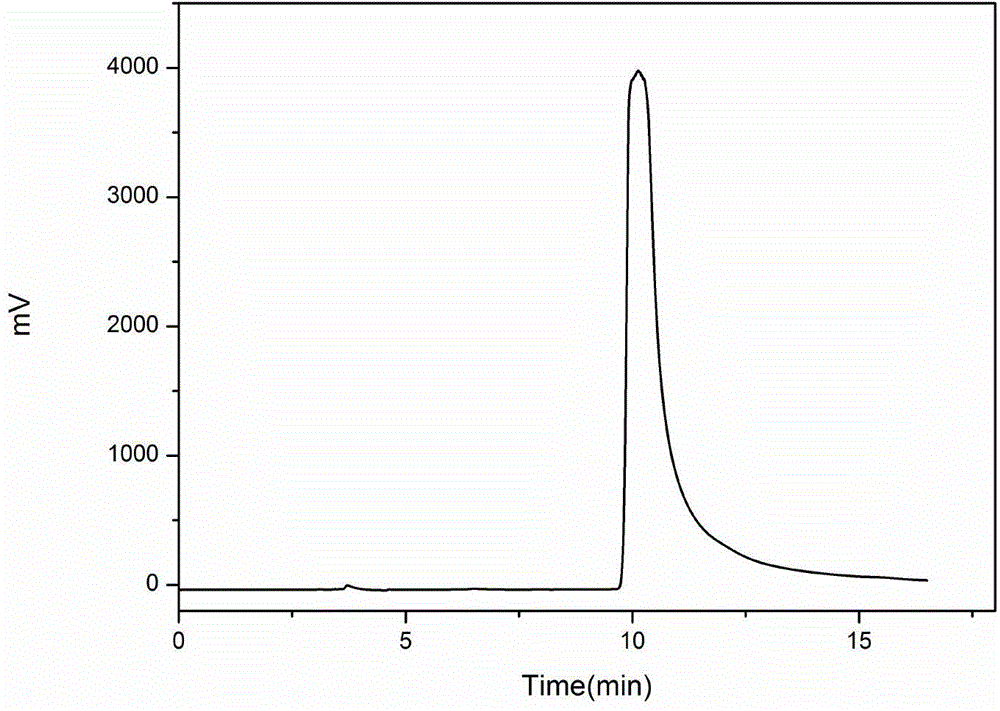

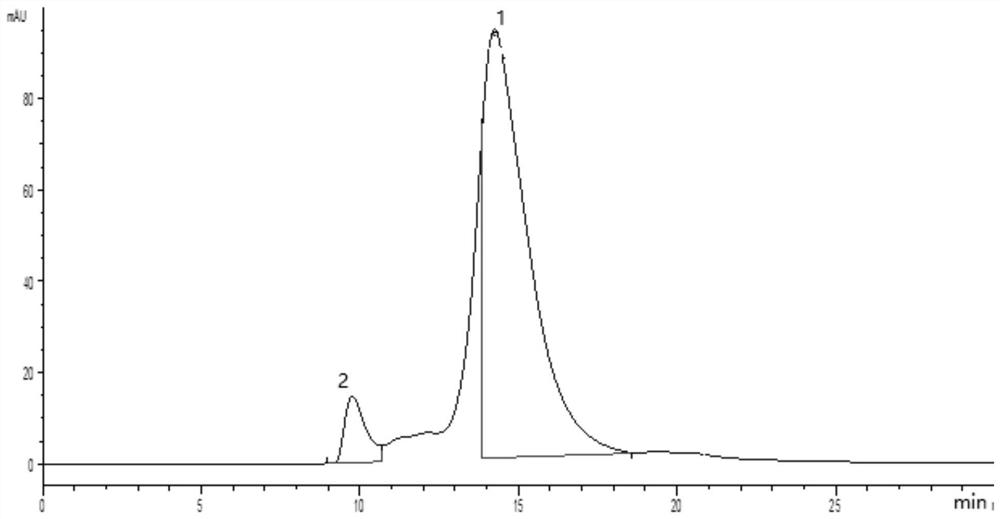

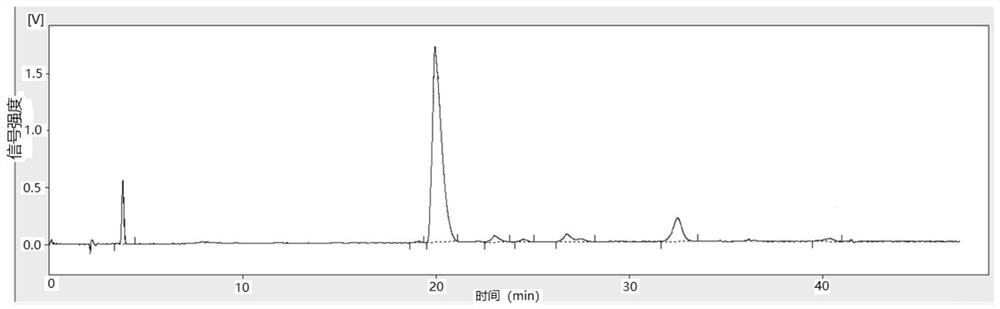

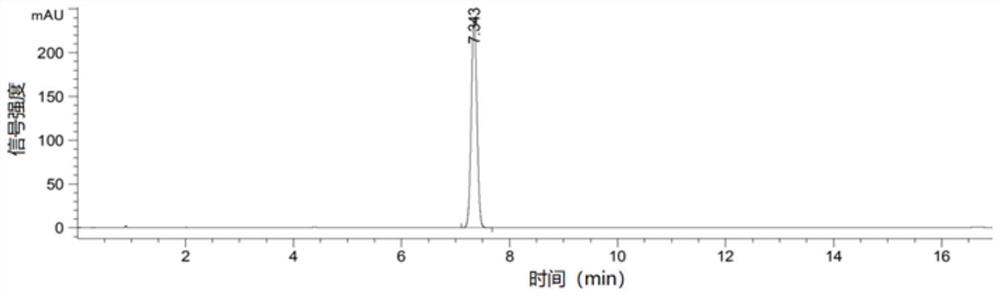

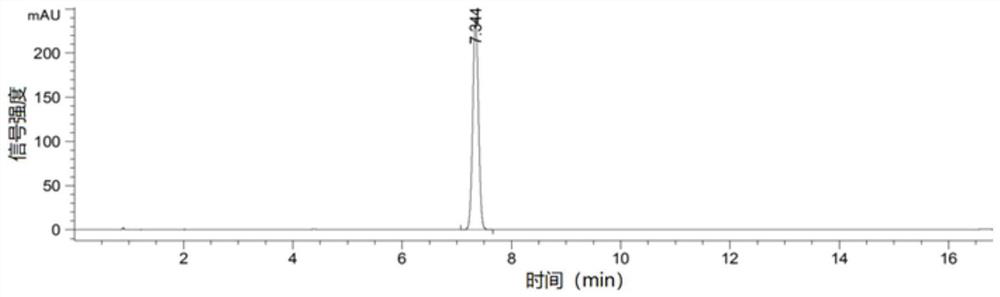

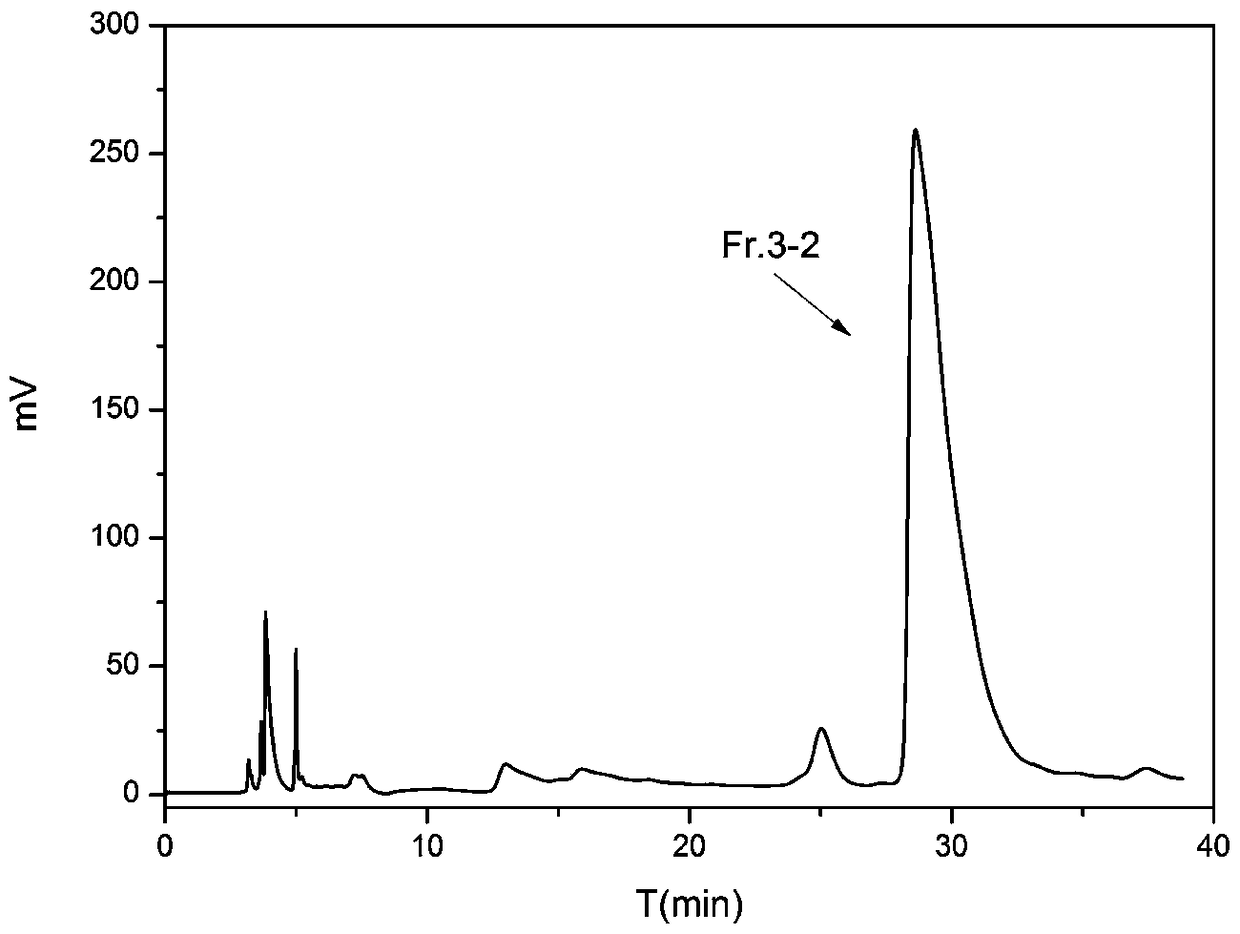

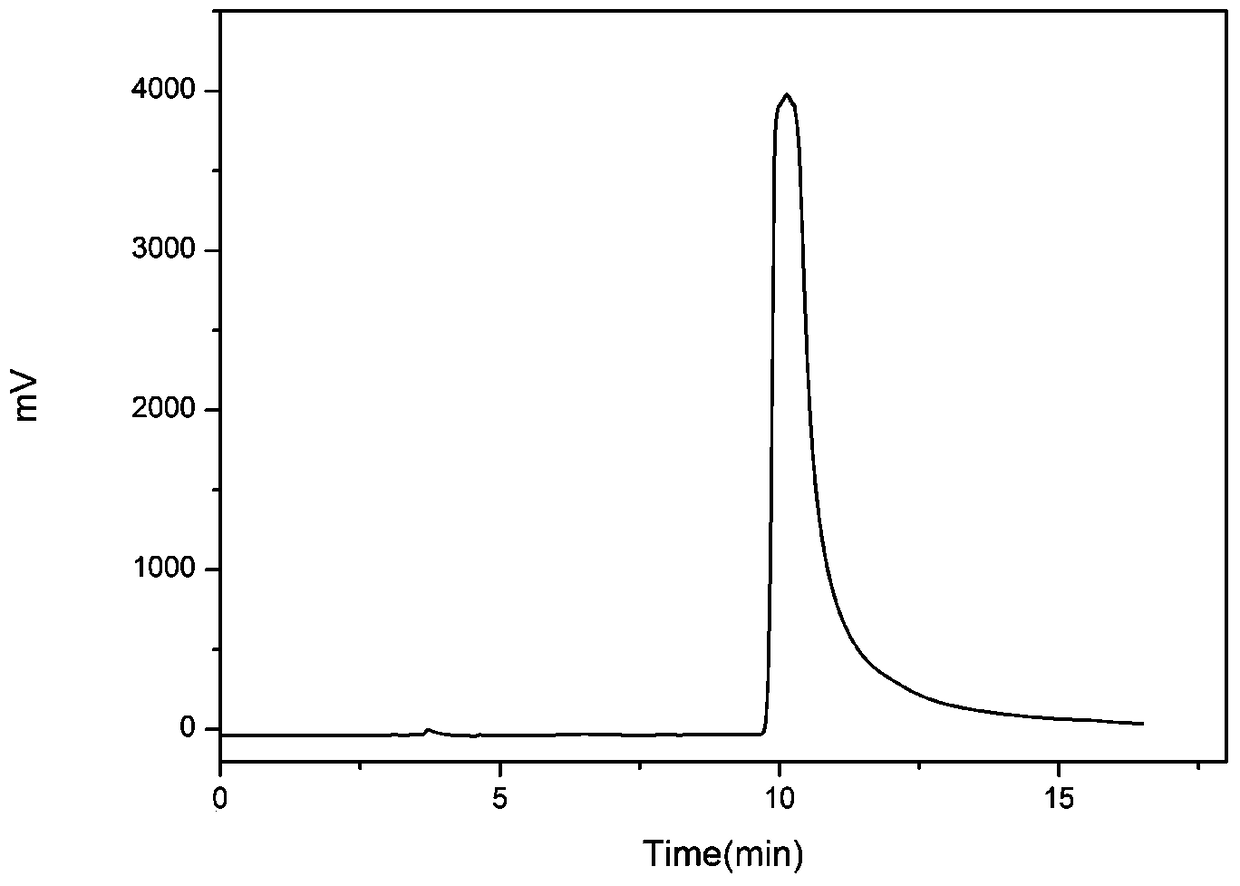

A method of separating and purifying quercetagetin from tagetes erecta is provided. The method includes a step of drying tagetes erecta dry flowers, grinding into powder, dipping with ethanol or performing reflux extraction, subjecting a filtrate after filtration to rotary evaporation until a product is dry and dissolving the product to a methanol-water mixed solvent; a step of performing one-dimensional liquid chromatogram, wherein DAISO C18 is adopted as a chromatographic column, a mobile phase adopting water as an A phase and methanol as a B phase is adopted, isocratic elution is performed for 20 min with the concentration of the B phase in the mobile phase being 50-55%, eluate from the 6 min to the 12 min is collected according to an ultraviolet absorption spectrum, adopted as a target component, and subjected to rotary evaporation until a product is dry, and the product of the rotary evaporation is dissolved into the methanol-water mixed solution again; and a step of performing two-dimensional liquid chromatogram, wherein Acchrom X-Amide is adopted as a chromatographic column, a mobile phase adopting water as an A phase and acetonitrile as a B phase is adopted, isocratic elution is performed for 40 min with the concentration of the B phase in the mobile phase being 92-98%, and eluate from the 27 min to the 33 min is collected according to an ultraviolet absorption spectrum, adopted as the target component, and subjected to rotary evaporation until a product is dry to obtain quercetagetin the purity of which is 99% or above.

Owner:TIANJIN YAOYU BIOLOGICAL TECH

Method for separating and preparation of Gelsemium elegans alkaloid monomer by high speed counter current chromatography

ActiveCN101323618BSimple and fast operationShort separation cycleOrganic chemistrySolid sorbent liquid separationGelsemium elegansGelsemium

The invention discloses a method for separating and preparing a gelsemium alkaloid monomer from gelsemium by adopting high-speed counter current chromatography, which pertains to the separation method of medicinal plant monomers. The invention takes total alkaloids of gelsemium as a raw material and a high-speed counter current chromatograph as a separating device and the method comprises that a solvent system which is composed of stationary phase and mobile phase is prepared; the high-speed counter current chromatograph is filled with the stationary phase and then the mobile phase is pumped in and balanced; and then sampling is conducted by a sample valve; target components are collected according to the map of a detector or in combination of the detection methods of high efficiency liquid chromatography and thin layer chromatography, and distilled under reduced pressure and then recrystallized to obtain the gelsemium alkaloid monomer with high purity. By adjusting the specific proportional parameters of the solvent system, single or multiple target gelsemium alkaloid monomers can be separated by one step or step by step. The method is convenient and efficient, large in preparation amount, less in sample loss, good in separation effect and high in controllability and applicable to automatic production and the obtained gelsemium alkaloid monomer from separation has diverse pharmacological activities and application prospect to be prepared into medicines.

Owner:FUJIAN MEDICAL UNIV

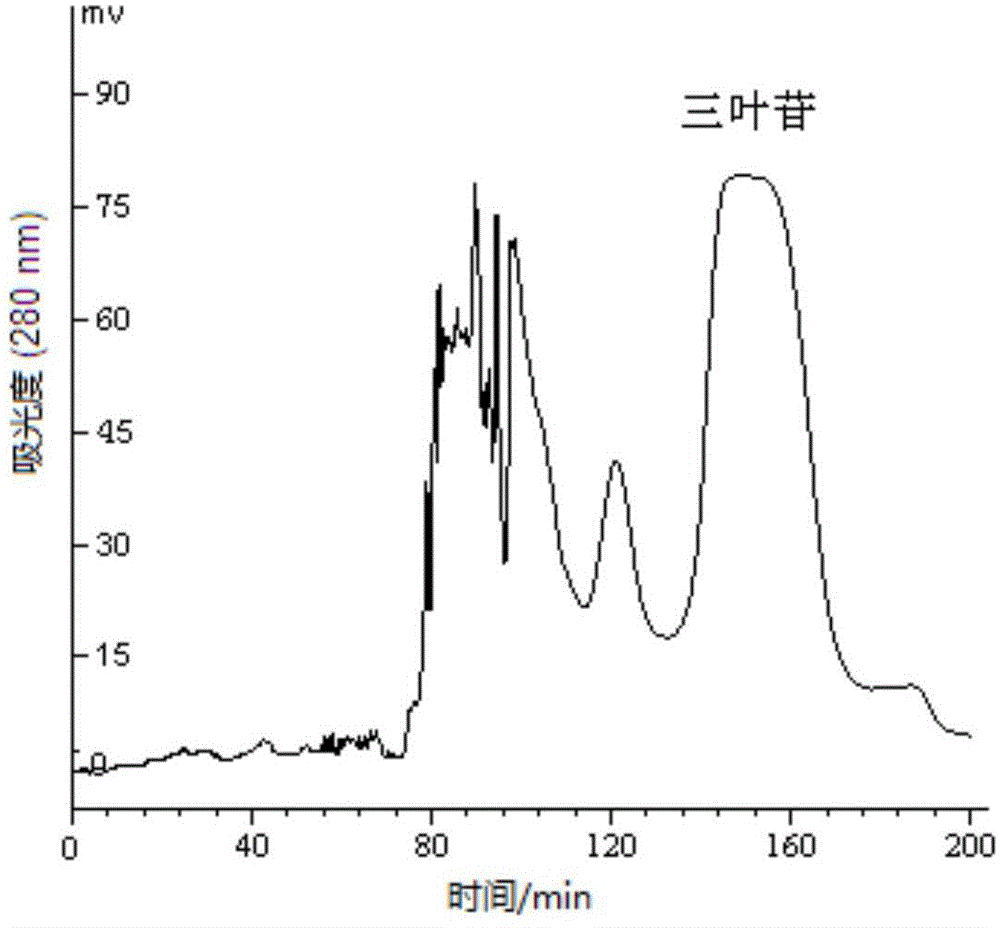

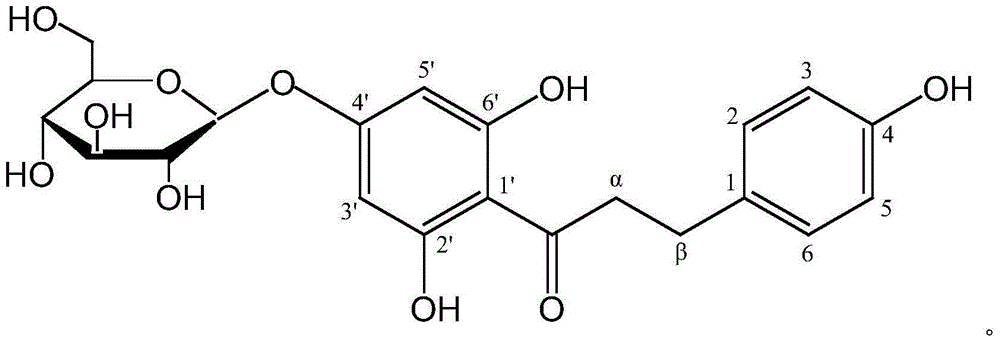

Mass isolation method of natural sweetener Trilobatin

ActiveCN104974201AThe separation method is simpleFast separation methodSugar derivativesSugar derivatives preparationAcetic acidReflux

The invention provides a mass isolation method of a natural sweetener Trilobatin. The method comprises the following steps: adding a crushed Trilobatin raw material into 30-90% (by volume) of ethanol according to the solid-to-liquid mass ratio of 1:10-50, carrying out thermal reflux for separation, filtering a separating medium to obtain filter residue and a filtrate, and carrying out vacuum concentration on the filtrate until there is no alcohol taste so as to obtain an isolate; dissolving the isolate by adding water, extracting with ethyl acetate, and carrying out vacuum concentration on an extract liquor to obtain an ethyl acetate extract; and separating the ethyl acetate extract by high-speed countercurrent chromatography so as to obtain the natural sweetener. The isolation method is simple and fast and has short isolation cycle. Monomers preparation amount is large, and monomers have multiple pharmacological activities.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

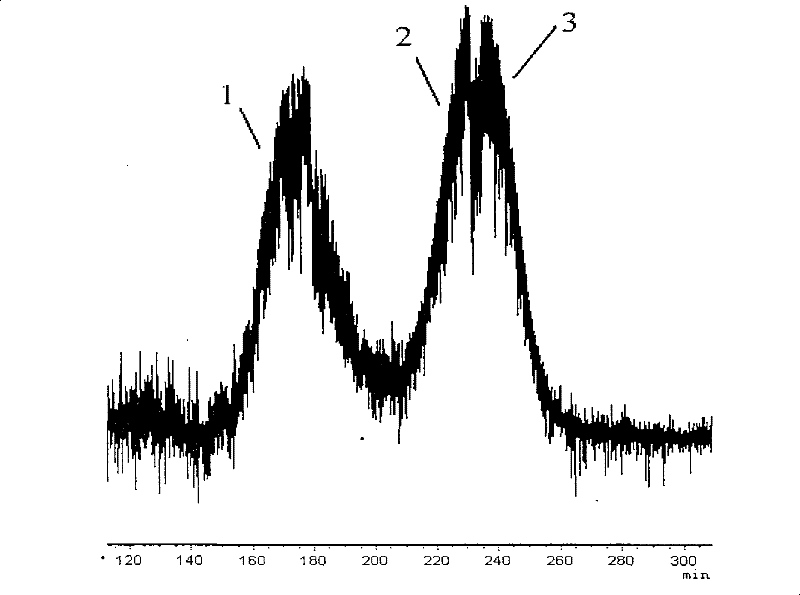

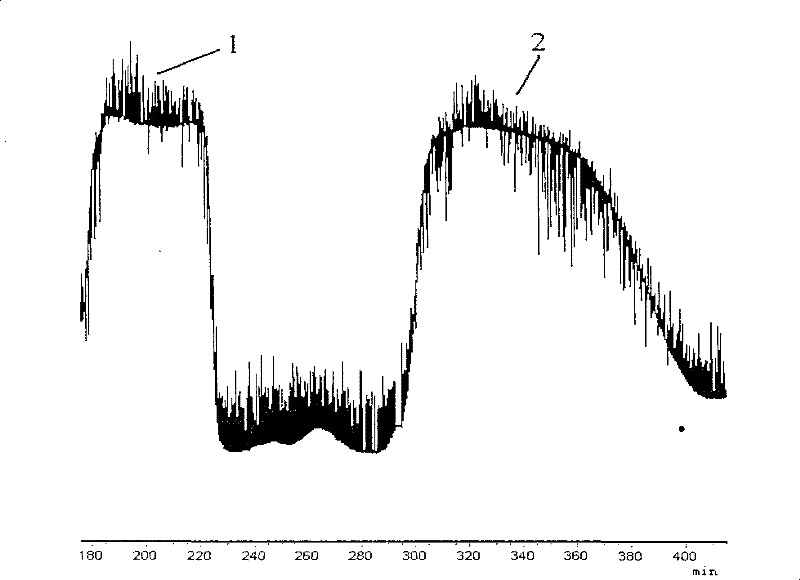

Process for preparing thermopsis lanceolate total alkaloids and several high-purity medicinal substances

InactiveCN102349940AReduce usageImprove stabilityNervous disorderAntimycoticsCountercurrent chromatographyAcid water

The invention relates to a process for preparing thermopsis lanceolate total alkaloids and several high-purity medicinal substances, and belongs to the technical field of the extraction of Chinese medicinal active ingredients. The medicinal substances comprise eulexine, thermopsine, sparteine and N-methyl eulexine. In the process, total alkaloids are prepared from thermopsis lanceolate serving as a raw material through acid water extraction, ionic resin adsorption and macroporous resin enrichment, and the total alkaloids are separated and purified by high-speed countercurrent chromatography and preparative liquid chromatography to obtain the high-purity eulexine, thermopsine, sparteine and N-methyl eulexine. The process has the advantages of simplicity, quickness, high repeatability, large preparation amount and the like, and industrialization is easy to realize.

Owner:NANJING ZELANG MEDICAL TECH

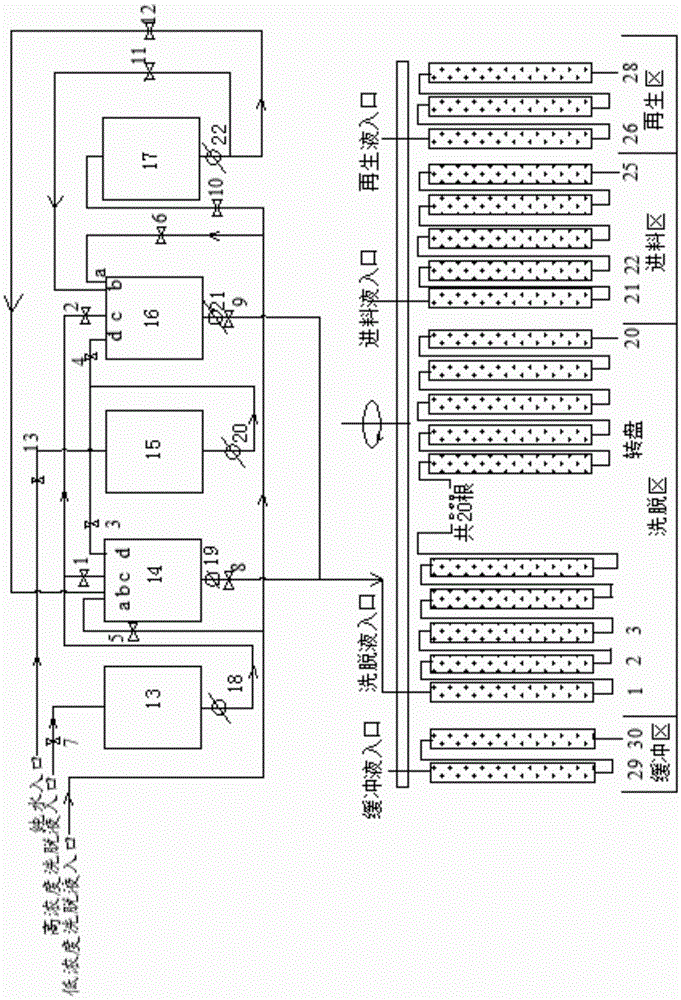

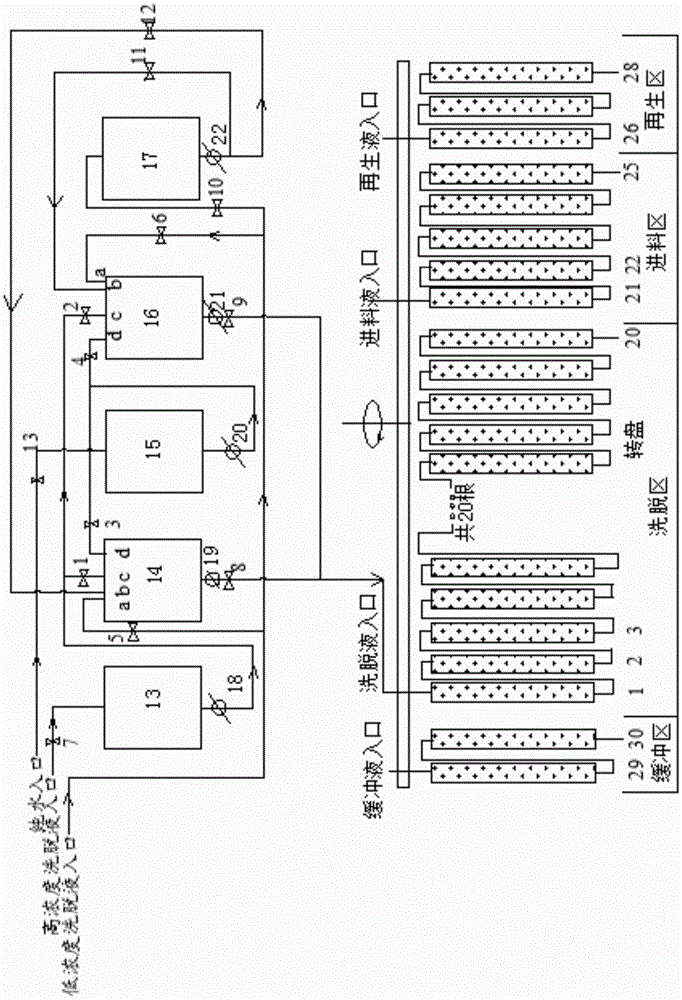

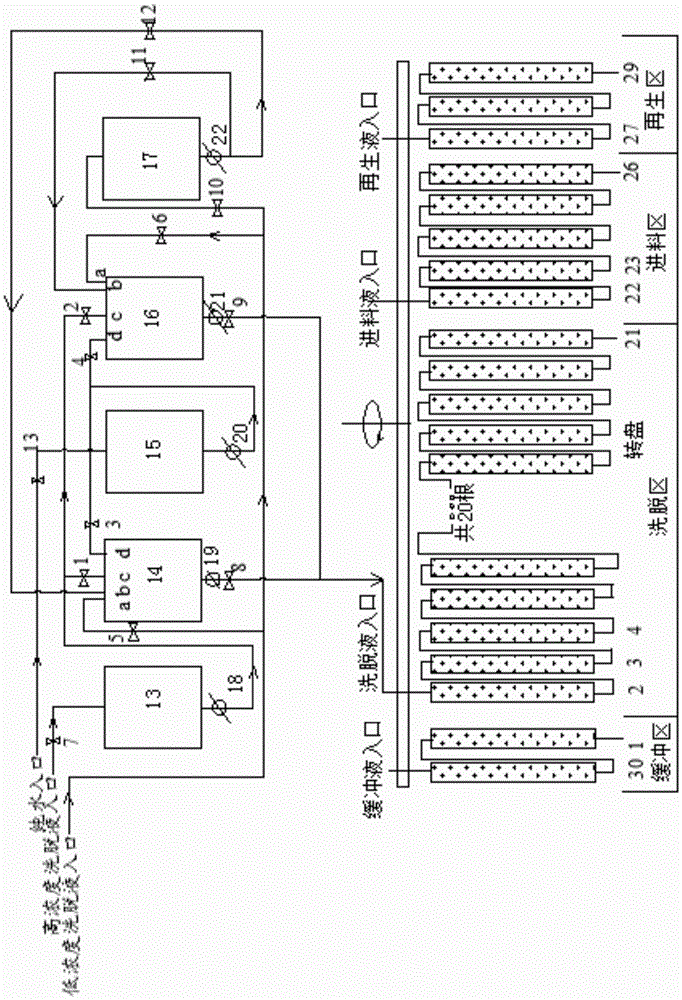

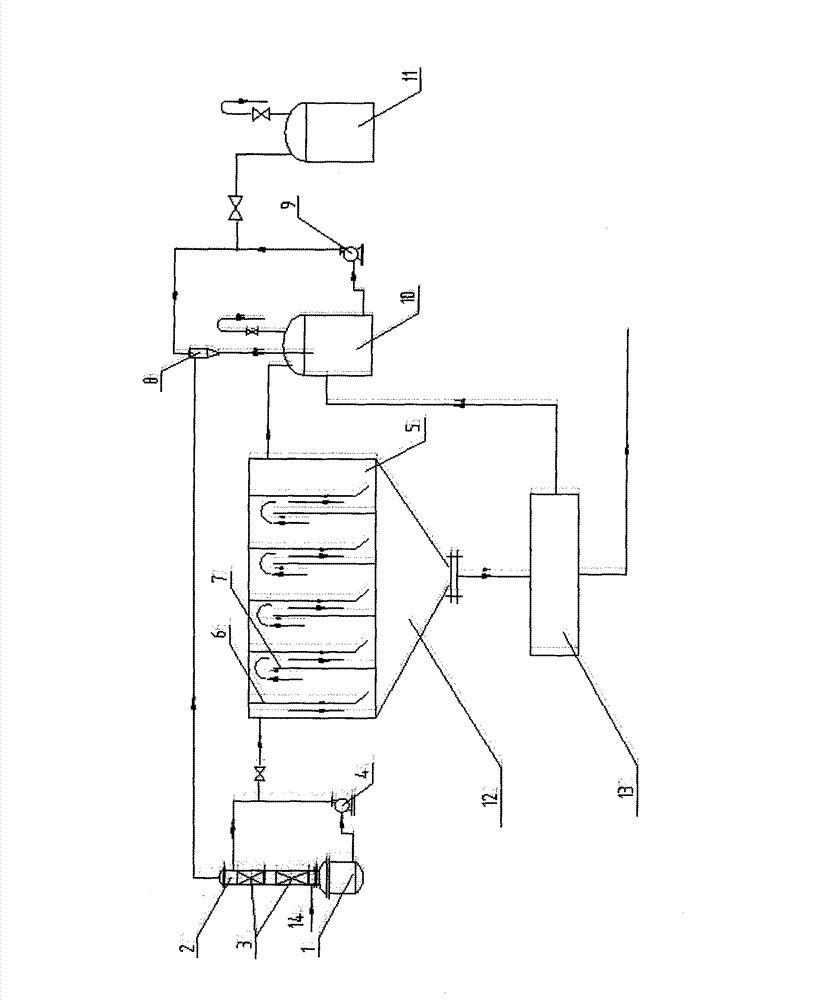

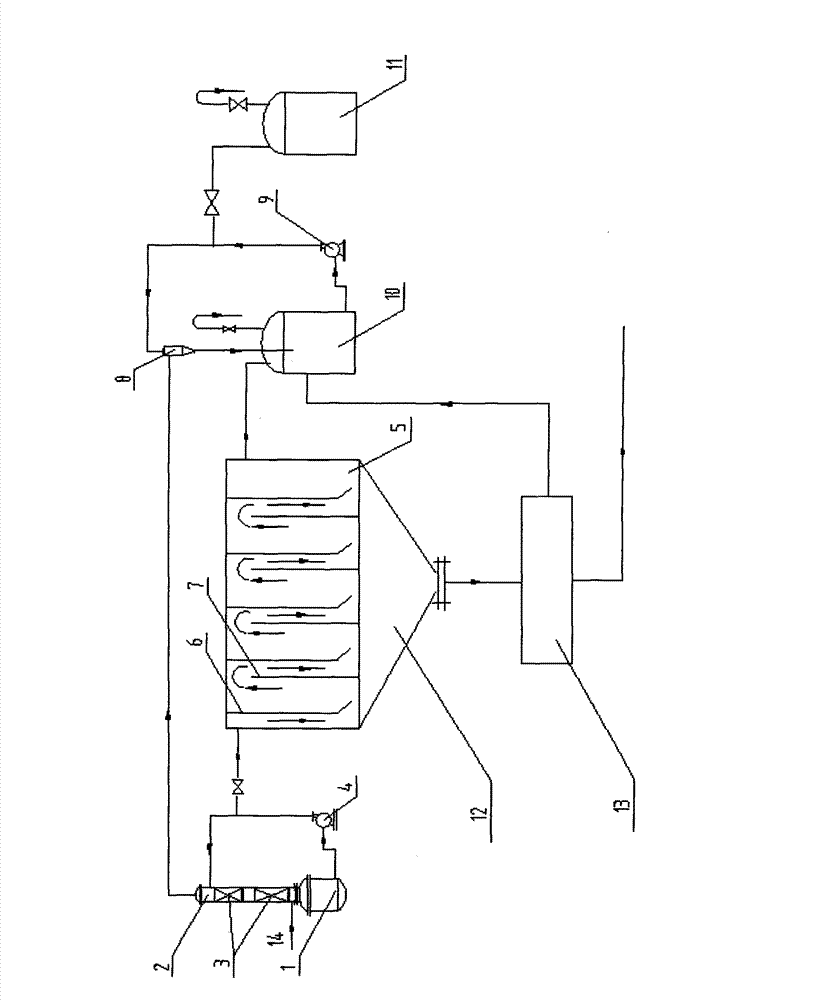

Continuous gradient elution system based on stimulated moving bed and treatment method of continuous gradient elution system

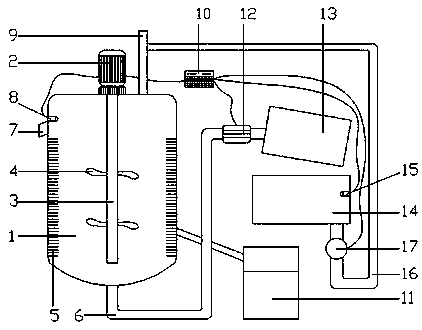

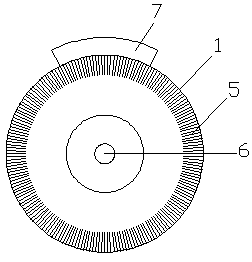

ActiveCN105597371AShort migration distanceGood elution separation effectSolid sorbent liquid separationSeparation factorSimulated moving bed

The invention provides a continuous gradient elution system based on a stimulated moving bed (SMB) and a treatment method of the continuous gradient elution system. The continuous gradient elution system comprises the SMB and a matched device connected with a single chromatographic column in an elution area of the SMB, and the matched device comprises five liquid storage tanks, thirteen valves and five pumps. Gradient elution liquid can be continuously and periodically supplied to each chromatographic column in the elution area of the SMB. Each time when a turnplate of the SMB rotates by a cell, and both the gradient elution process and a mode of gradient elution liquid concentration increase with time of each chromatographic column are completely coincident with that of the previous chromatographic column, so that gradient elution of each chromatographic column in the elution area is realized. The continuous gradient elution system has good elution and separation effect; with equal elution flow, single-stage separation factor of a to-be-separated target component is greater than isocratic elution, band migration distance needed for separating to obtain a target product is short, separation period is short, process operation is simple, and programmed operation control can be realized easily.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

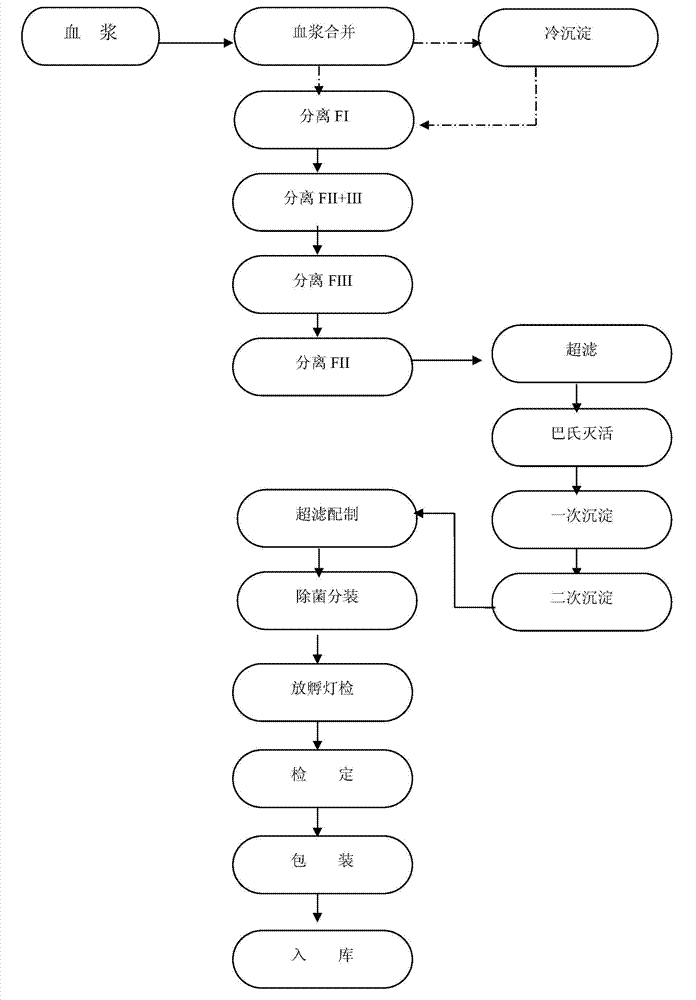

Method for extracting intravenous injection human immunoglobulin by low temperature ethanol

InactiveCN103665100AHigh clarityReduce and remove anti-complement activityPeptide preparation methodsUltrafiltrationCLARITY

The invention discloses a method for extracting intravenous injection human immunoglobulin by low temperature ethanol. In the method, FI, FII+III, FIII and FII are sequentially separated; and when FII precipitates are subjected to ultrafiltration and purification, processes of ultrafiltration dealcoholization, Pasteur inactivation, primary precipitation separation, secondary precipitation separation and secondary precipitation ultrafiltration dealcoholization are sequentially adopted. According to the invention, in the filtering process, the temperature of a filter press is controlled in a low-temperature range; the proper electrical conductivity is adopted in the precipitation separation processes; yield of the immunoglobulin is improved; when the immunoglobulin is purified and refined, precipitation separation is carried out for twice; secondary clarification sterilization filtration is adopted in the process of carrying out precipitation separation for twice; and by a four-stage filtering technology, insoluble particles in a product are removed and clarity and yield of the product are improved.

Owner:HUALAN BIOLOGICAL ENG CHONGQING

Method for simultaneously separating three main components of bovine milk casein

ActiveCN107840883ARealize industrial preparationSimple processPeptide preparation methodsAnimals/human peptidesBiotechnologyIon exchange

The invention discloses a method for simultaneously separating three main components of bovine milk casein, and aims to provide a method for separating the three main monomer components of casein, which adopts the bovine milk casein as a raw material, adopts a DEAE ion exchange column as separating equipment, and can simultaneously obtain alpha-casein, beta-casein and kappa-casein through one-timeseparation. According to the method provided by the invention, the three casein monomer components can be obtained through one-step separation, separation steps are less, a separation process is simple and easy to operate, a separation condition is mild and easy to implement, the separating equipment is simple and easy, the dosage of chemical reagents is less during a separation process, not onlyis the separation cost of the casein monomers reduced, but also the environment pollution is reduced, and the method meets a new concept on low carbon and environment protection; the average yield for separating the casein monomers is high, the average yield of the alpha-casein can reach 75 percent or more, the average yield of the beta-casein can reach 80 percent or more, and the average yield of the kappa-casein can reach 85 percent or more; the obtained three casein monomers have high purity which can reach to 95 percent or more; the method not only can meet the requirement on preparing the three high-purity casein monomer components in a laboratory, but also can be used for industrially preparing the main monomers of the casein, and is wide in application range.

Owner:GANSU AGRI UNIV

Method for separating and purifying lecithin through fixed-bed adsorption method

ActiveCN103254226AIncrease consumptionEasy to handleIon-exchange process apparatusIon-exchanger regenerationDistillationSorbent

The invention discloses a method for separating and purifying lecithin through a fixed-bed adsorption method. The method comprises the following steps of: dissolving a phosphatidylcholine raw material in a solvent to prepare a raw material liquid, enabling the raw material liquid to continuously pass through an adsorption column filled with an adsorbent to ensure that impurities in the raw material liquid are preferentially adsorbed, collecting an effluent liquid at an outlet of the adsorption column, enabling the effluent liquid to be subjected to reduced pressure distillation and concentration and obtaining a phosphatidylcholine product, wherein the impurities are cephalin, phosphatidylserine and sphingomyelin. The method disclosed by the invention has the advantages that by adopting a continuous feeding mode, the main impurities such as the cephalin, the phosphatidylserine, the sphingomyelin and the like in the phosphatidylcholine raw material liquid can be removed through a single adsorption operation, so that the process flow of purifying the phosphatidylcholine is greatly simplified and the phosphatidylcholine yield is increased.

Owner:ZHEJIANG UNIV

Method for extracting cucurbitacin B

The invention relates to a method for extracting cucurbitacin B. The method comprises the following steps of: crushing a raw material of muskmelon pedicel, and wetting the crushed muskmelon pedicel with acidic water; adding a biological enzyme for enzymolysis for 2-4 days at 30-40 DEG C; extracting zymolytic raw materials 2-3 times with 80-95% ethanol; enabling the extracting solution to flow by a short active carbon alumina column and then concentrating until the ethanol concentration is 30-50 percent; standing and crystallizing; carrying out the cold dissolution treatment with chloroform for secondary crystallization; and dissolving under the refluxing of 90-99% ethanol, decoloring with active carbon, removing impurities, recrystallizing, and the like. The method adopted for producing the cucurbitacin B has the advantages of high product yield, low cost and simple process and is easy to operate. The invention is suitable for industrial production.

Owner:NANJING ZELANG AGRI DEV

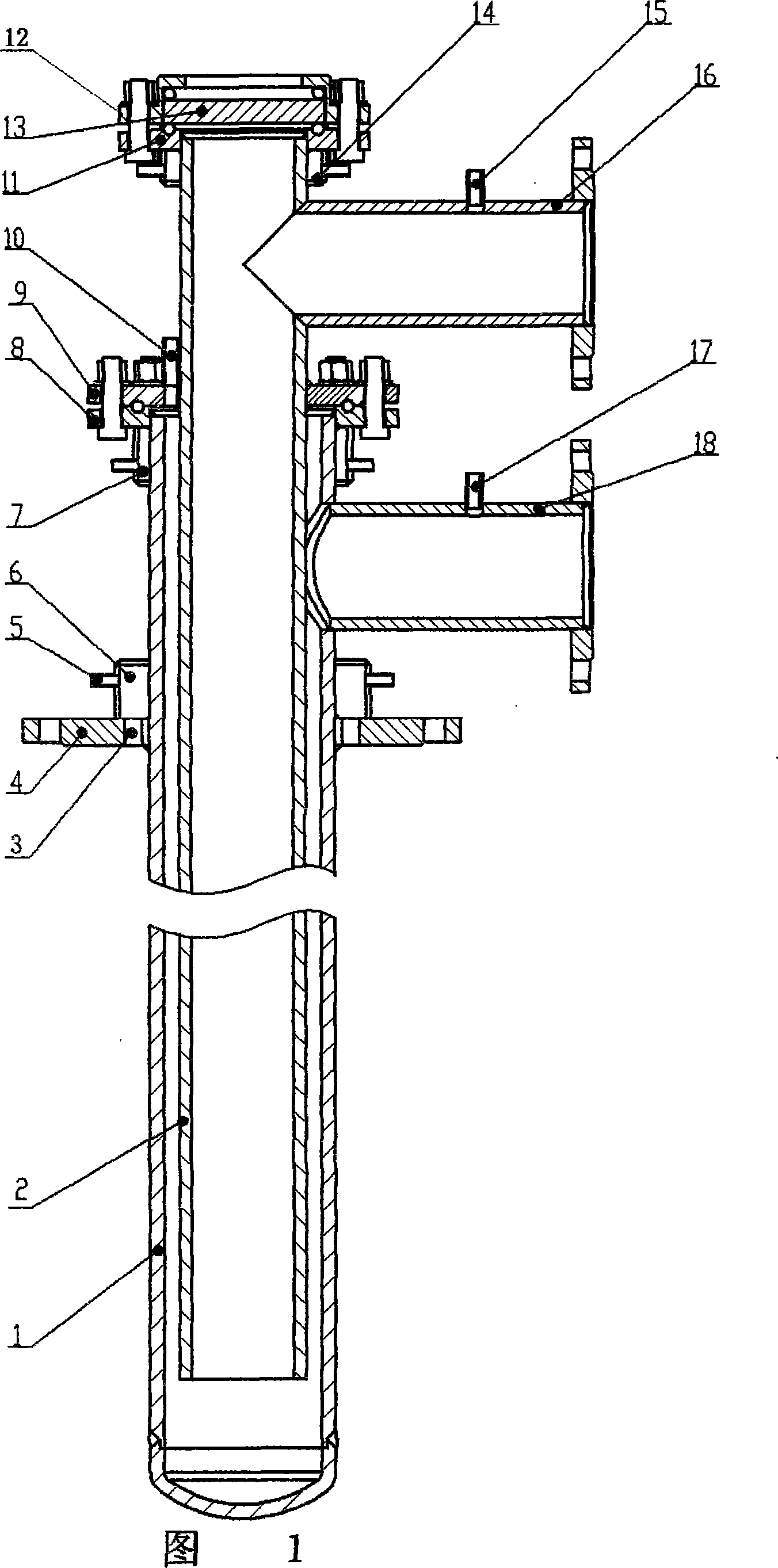

Method and device for magnesium method titanium sponge production reactor inner heat exchange

An internal heat exchange method of the production reaction vessel made of magnesium spongy titanium and the equipment of it. The method is as following, the heat exchanger will be inserted into the inner of the reactor, and air-blown medium will be input into the heat exchanger to cool the magnesium spongy titanium in the reactor. The above heat exchanger is tube-in -tube heat exchanger, and the air-blown medium is compressed air and compressed argon. The equipment is tube-in -tube heat exchanger, the inside tube is installed in outer tube by the ring flange, intake tube will be installed on the upside profile of the inside tube, the sihghtglass will be installed on the top of the inside tube, the return tube will be installed on the topside profile of the outer tube. The assemblage ring flange used to connect with the reactor will be installed under the joint between the outer tube and the return tube. The ring shaped charging box will be welded to the outside of the tube-in -tube heat exchanger and the upside of the assemblage ring flange, several feed openings connected with the ring charging box locate uniformly on the ring flange along the circle. The locally high temperature can be banished by this method and this equipment, and the densification of the product can be prevented. And it can also shorten the production cycle, and improve the production energy.

Owner:中信钛业股份有限公司

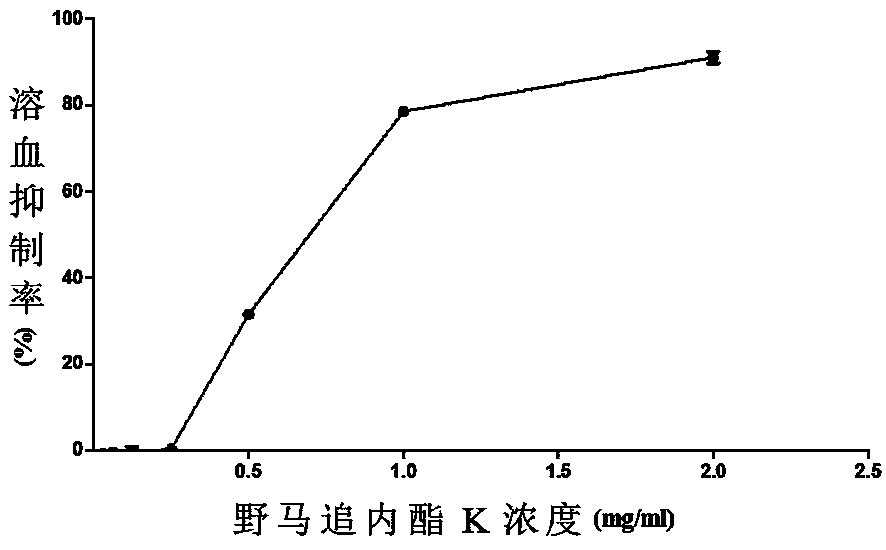

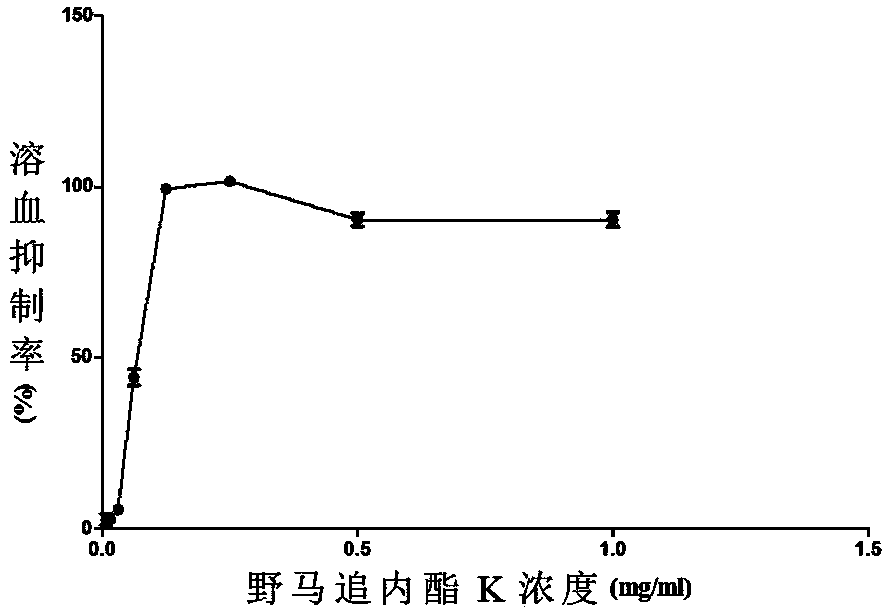

Application of Eupalinolide K in preparing anticomplement drugs

InactiveCN103520153AEasy to separateShort separation cycleOrganic active ingredientsBlood disorderDrugMedicine

Owner:SUZHOU UNIV

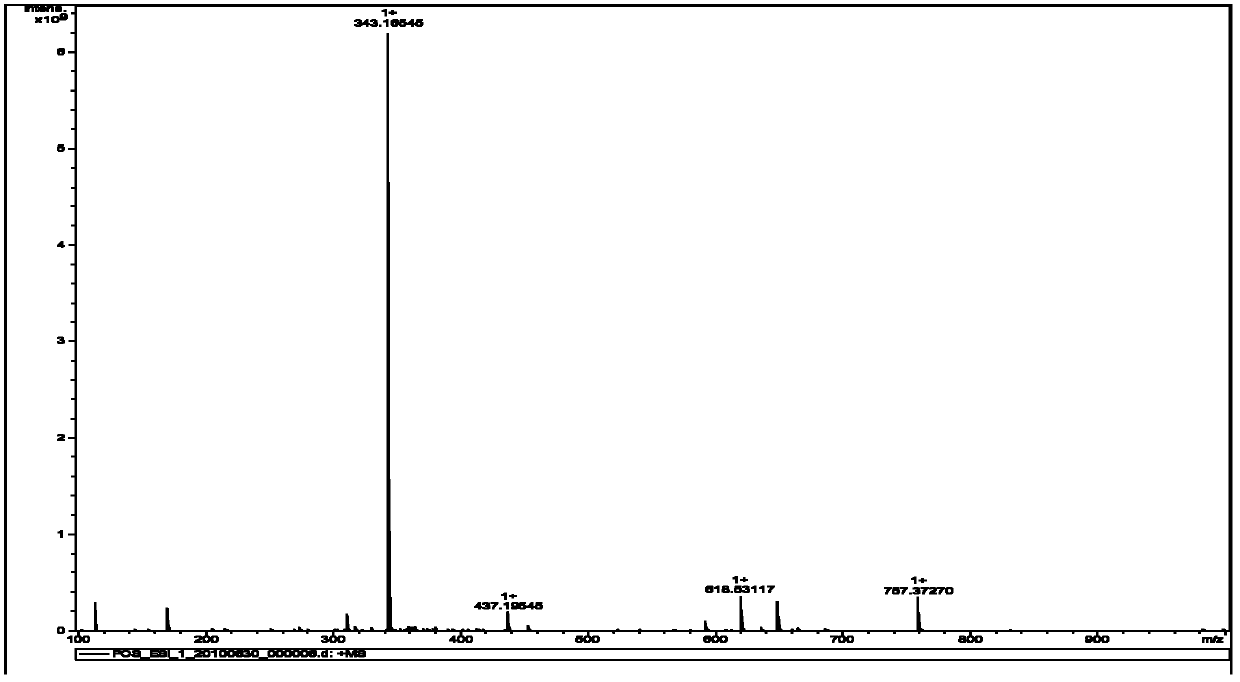

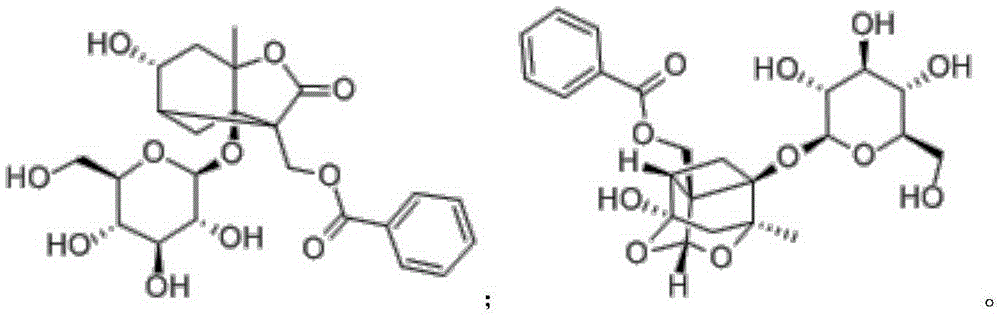

New Gelsmium elegans Benth. alkaloid compound as well as preparation method and application thereof

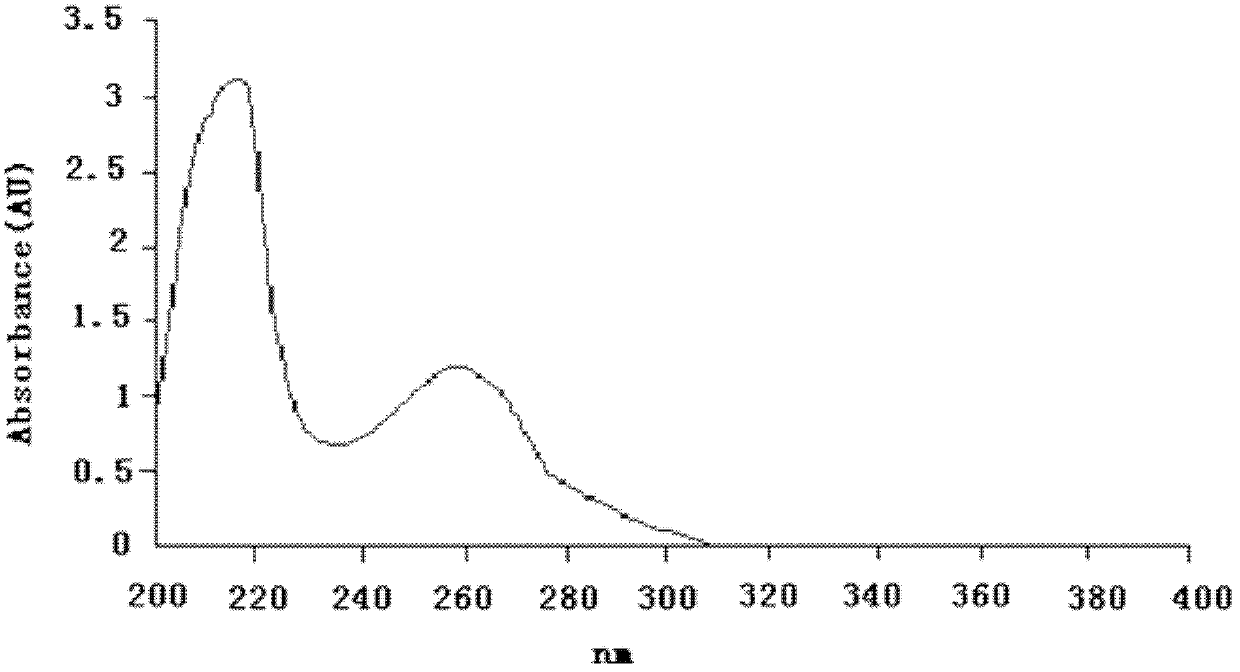

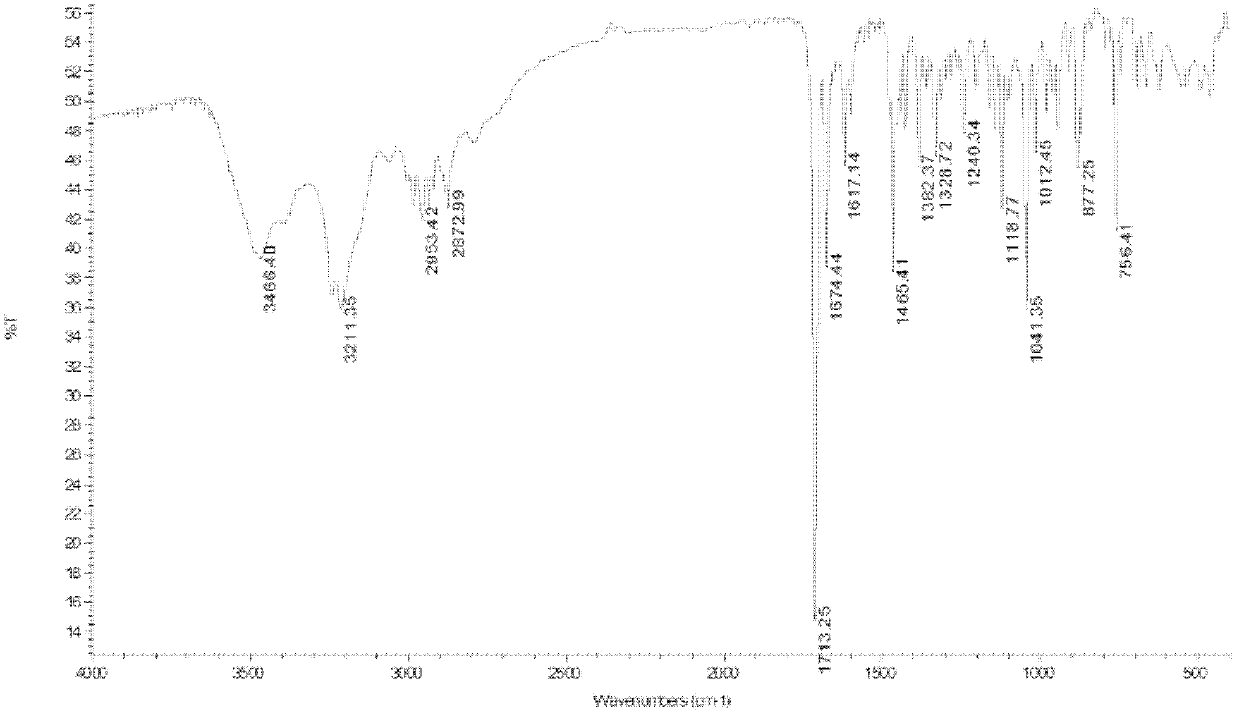

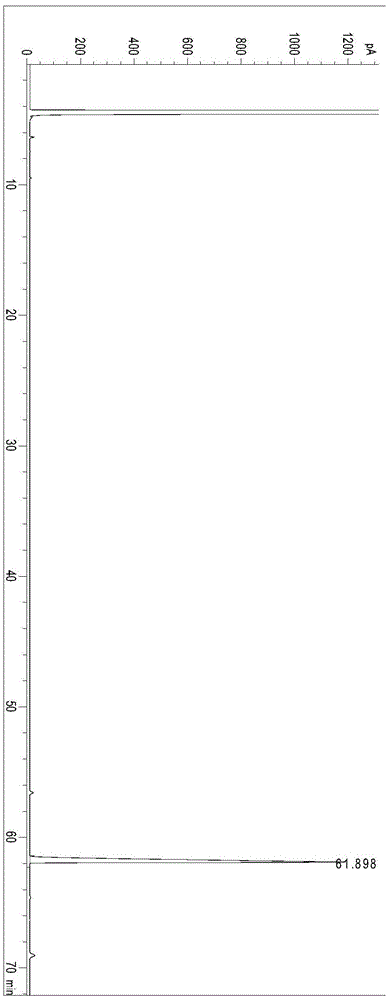

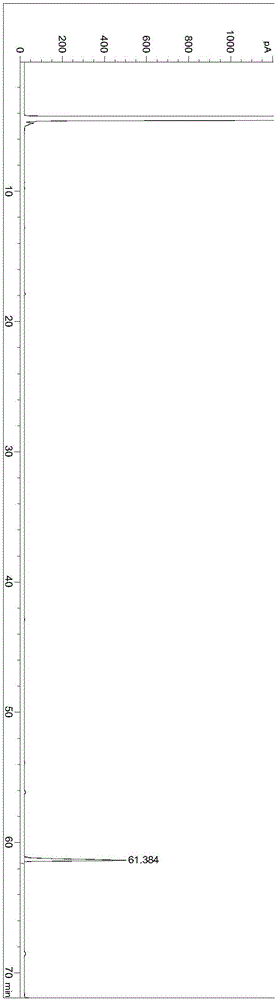

ActiveCN102321094AHigh yieldShort separation cycleOrganic active ingredientsOrganic chemistryInfraredResolution (mass spectrometry)

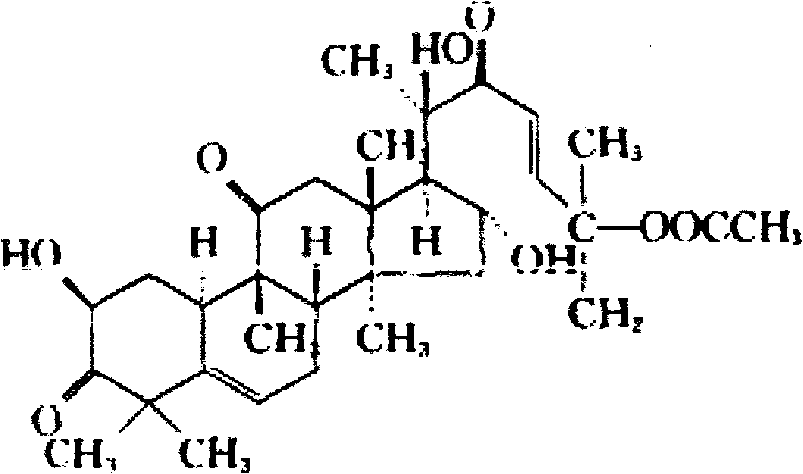

The invention discloses a new Gelsmium elegans Benth. alkaloid compound as well as a preparation method and application thereof. In the preparation method, a target compound is separated from Gelsmium elegans Benth. by using a pH-zone-refining countercurrent chromatography and taking a total Gelsmium elegans Benth. alkaloid crude extract as a raw material and a high-speed counter-current chromatographic instrument as separation equipment; and the method has the advantages of large preparation amount, less sample loss and strong controllability, and is convenient and fast and is suitable for industrial production. By the determination of high-resolution mass spectrometry, ultraviolet spectrum, infrared spectrum, <1>H, <13>C-NMR (nuclear magnetic resonance) spectrum, <1>H-<1>HCOSY (correlation spectrometry), HSQC (heteronuclear single quantum coherence) spectrum and HMBC (heteronuclear multiple-bond correlation) spectrum, the new Gelsmium elegans Benth. alkaloid compound has the structure of a formula (I). A pharmacological test shows that the compound in the invention has dose dependence, powerful analgesic effect, less tolerance, addiction and side effect and treatment index far higher than that of total Gelsmium elegans Benth. alkaloid, can be used for preparing a novel powerful low-toxicity medicament or lead compound used for treating pain, and has definite industrial prospect.

Owner:FUJIAN MEDICAL UNIV

Method of separating preparation of volatile components from acorus tatarinowii

InactiveCN105130762AReduce mass transfer resistanceEasy to recycleEther separation/purificationBulk chemical productionOrganic solventSimple sample

The invention relates to a method of separating preparation of volatile components from acorus tatarinowii, wherein the volatile components can include monomer compounds or a composition thereof. The method comprises following steps: (A) with the volatile components as a raw material, extracting a crude volatile extract from the acorus tatarinowii; (B) dissolving the crude volatile extract in an organic solvent to prepare a sample solution for separating preparation; and (C) performing separating preparation to the solution through super-critical fluid chromatography technology to obtain the acorus tatarinowii volatile components. In the method, the acorus tatarinowii volatile components are separated and prepared through the super-critical fluid chromatography technology, and at the same time, a new approach of preparing [alpha]-asarone, [beta]-asarone and [gamma]-asarone is developed. Through the super-critical fluid chromatography technology, the [alpha]-asarone, the [beta]-asarone and the [gamma]-asarone are prepared synchronously just through simple sample injection and separation at a high purity. The method is high in yield of products, is short in separation time and is high in efficiency.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD

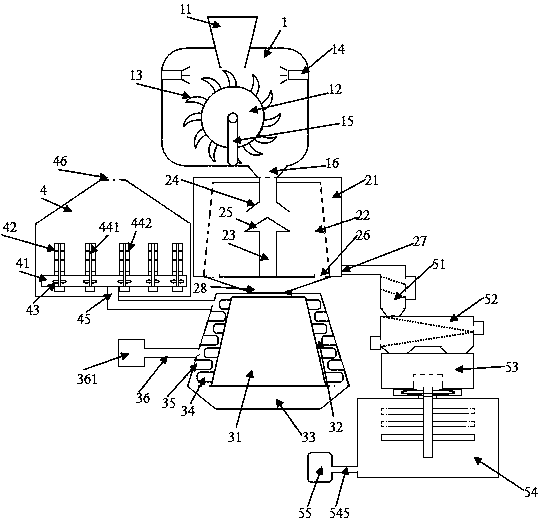

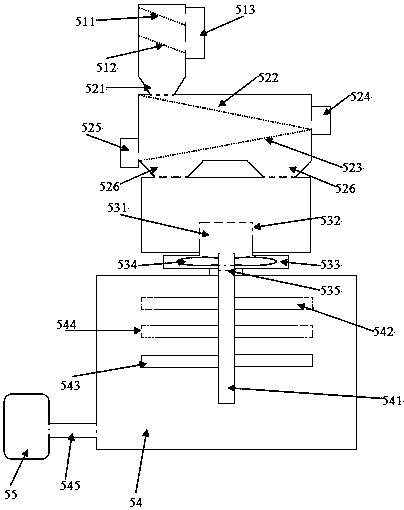

Clean treatment device of compound fertilizer granulation tail gas

InactiveCN103084035ASettling separation period is shortEasy to separateCombination devicesFiltrationResource saving

The invention relates to a clean treatment device of compound fertilizer granulation tail gas, belonging to recycling of industrial waste gas carrying materials. The device comprises a dust recovery unit and a water washing treatment unit, wherein the water washing treatment unit comprises a treatment process of vacuum water washing, sealed flow deflection settling, and ammonia gas salification and fixation. The treatment process comprises the following steps: (1) vacuum water absorption; (2) sealed flow deflection settling; (3) ammonia gas salification and fixation; and (4) pressure filtration. The clean treatment device of compound fertilizer granulation tail gas does not need any acidification or neutralization section, and has the advantages of short period for solid-liquid settlement separation and favorable separating effect; in the solid-liquid separation process and use process, little ammonia gas escapes; and the method is beneficial to resource saving and environment protection. The invention is suitable for recycling tail gas generated by a compound fertilizer or complex fertilizer granulation device.

Owner:韦子木

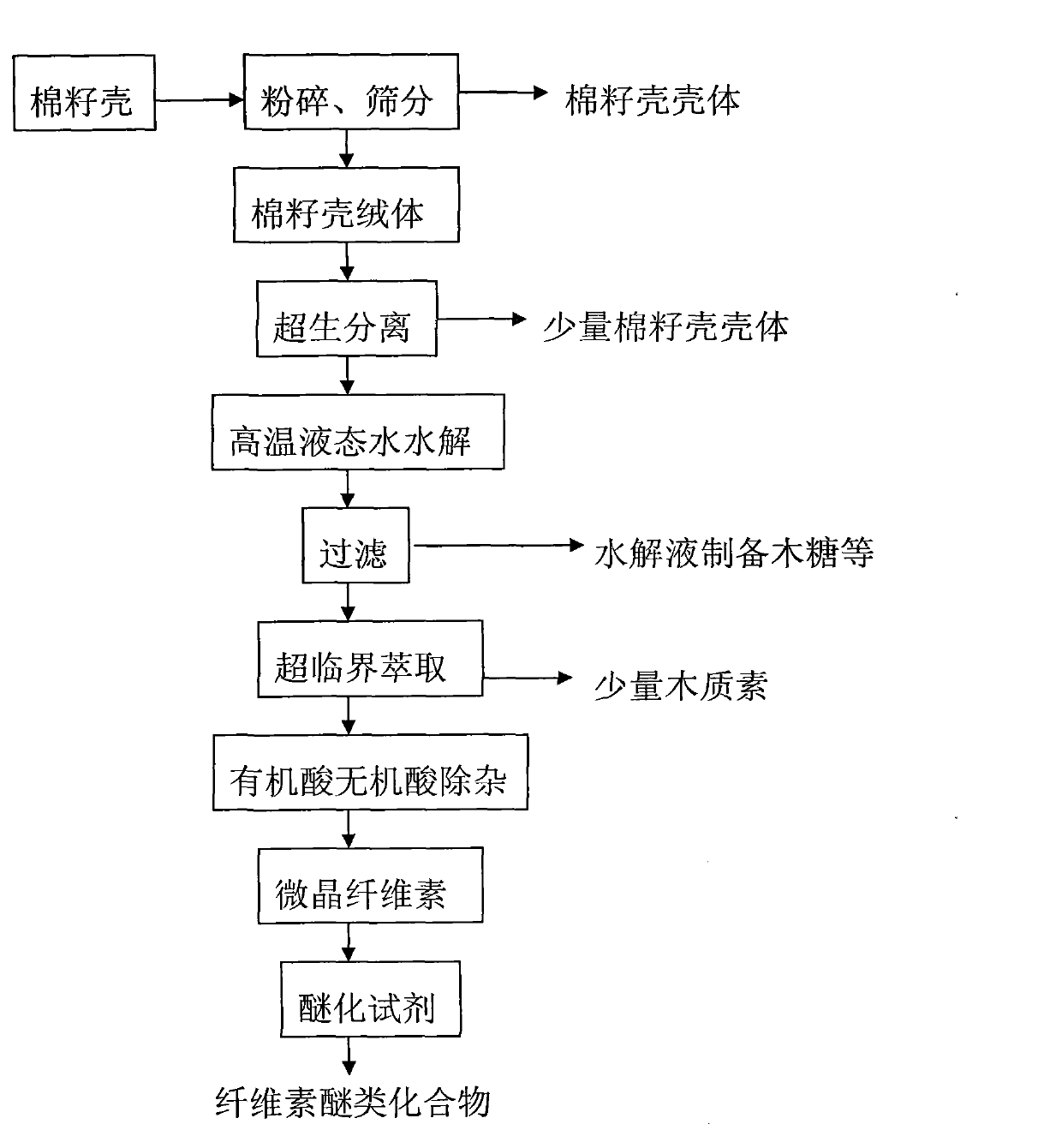

Method for preparing cellulose compounds by using cottonseed hull as raw material

InactiveCN103122034AReduce lossesLarge amount of processingBulk chemical productionCarbamateLiquid water

The invention discloses a method for preparing cellulose compounds by using a cottonseed hull as a raw material, which is realized by hydrolyzing hemicellulose of cottonseed hull staple by using high-temperature and high-pressure liquid water, removing lignin through supercritical extraction, removing a small amount of impurities by using organic acid and inorganic acid and simultaneously preparing microcrystalline cellulose. The method comprises the following steps: separating a hull wrapped by cottonseed hull staple through ultrasonic treatment, and hydrolyzing hemicellulose in the cottonseed hull staple by using liquid water at high temperature and high pressure; performing supercritical CO2 extraction, and adding a right amount of assistant to remove lignin, thus obtaining coarse cellulose; and removing a small amount of impurities by using organic acid and inorganic acid, and simultaneously preparing microcrystalline cellulose, wherein the prepared cellulose can react with chloroacetic acid, sodium hydroxide, urea, 3-chloro-2-hydroxypropyl trimethyl ammonium chloride and other reagents to be prepared into carbamate cellulose, carboxymethyl cellulose, hydroxyethyl methyl cellulose and other cellulose ether compounds. The method overcomes the defect of using a large amount of acid and alkali in the existing cottonseed hull cellulose recovery, has the advantages of quick and effective hemicellulose separation, low cellulose loss, obviously shortened separation period, low energy consumption and high cellulose product purity, and has remarkable economic benefits and social benefits.

Owner:TARIM UNIV

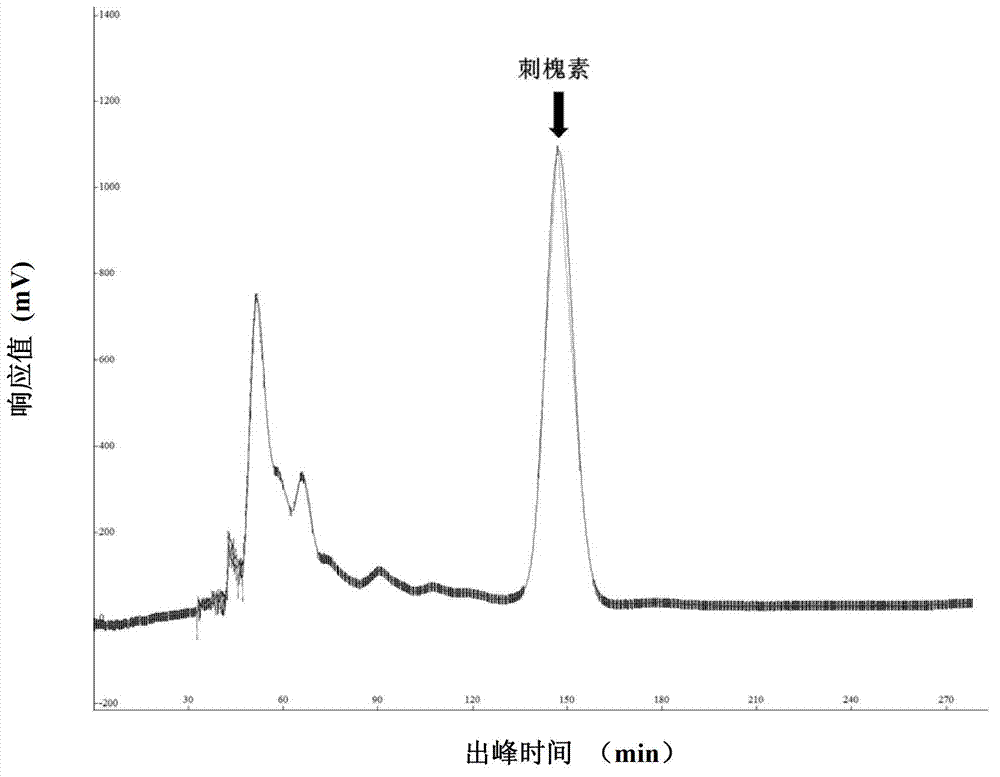

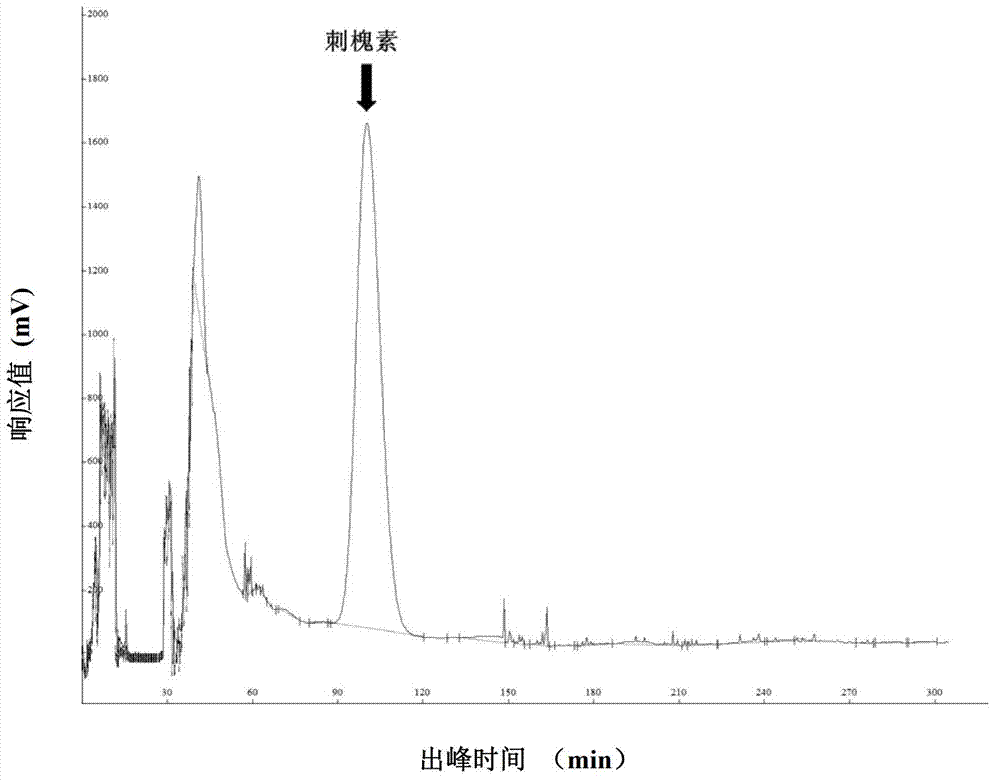

Method for separating and preparing robinin monomer from wild chrysanthemum flowers

The invention provides a method for separating and preparing robinin monomer from wild chrysanthemum flowers, relates to a method for processing wild chrysanthemum flowers, and provides a high separation efficiency and high recycling rate method for separating and preparing robinin from wild chrysanthemum flowers by adopting the high-speed counter-current chromatography. The method comprises the following steps of: 1) preparing a solvent system which forms a stationary phase and a moving phase, wherein the solvent system consists of normal hexane, ethyl acetate, methanol and water; 2) filling the stationary phase by using high-speed counter-current chromatographic instrument, and adjusting the moving speed of the moving phase and the rotating speed of a host, and pumping the moving phase for balancing; 3) feeding a sample by a feed valve; and 4) collecting a target component, reducing pressure, evaporating to dryness and re-crystallizing to obtain the robinin monomer.

Owner:XIAMEN UNIV

Clean treatment method of compound fertilizer granulation tail gas

ActiveCN103084034ASettling separation period is shortShort separation cycleCombination devicesFiltrationResource saving

The invention relates to a clean treatment method of compound fertilizer granulation tail gas, belonging to recycling of industrial waste gas carrying materials. The method utilizes a dust recovery unit and a water washing treatment unit, wherein the water washing treatment unit comprises a treatment process of vacuum water washing, sealed flow deflection settling, and ammonia gas salification and fixation. The treatment process comprises the following steps: (1) vacuum water absorption; (2) sealed flow deflection settling; (3) ammonia gas salification and fixation; and (4) pressure filtration. The clean treatment method of compound fertilizer granulation tail gas does not need any acidification or neutralization section, and has the advantages of short period for solid-liquid settlement separation and favorable separating effect; in the solid-liquid separation process and use process, little ammonia gas escapes; and the method is beneficial to resource saving and environment protection. The invention is suitable for recycling tail gas generated by a compound fertilizer or complex fertilizer granulation device.

Owner:山东青上化工有限公司

Separation and purification method of canine immunoglobulin and application of canine immunoglobulin

PendingCN112480246AHigh purityReduce yield lossSerum immunoglobulinsPeptide preparation methodsEthanol precipitationIntravenous gammaglobulin

The invention relates to a separation and purification method of canine immunoglobulin and application of the canine immunoglobulin, and the separation and purification method comprises the step of sequentially carrying out cation exchange chromatography and hydrophobic chromatography on a centrifugal supernatant of canine plasma to obtain the canine immunoglobulin. According to the separation andpurification method of the canine immunoglobulin, disclosed by the invention, the purity of the canine immunoglobulin can be improved by creatively carrying out a specific two-step chromatography combination mode, namely cation exchange chromatography and hydrophobic chromatography, on pretreated healthy canine plasma, so that the purity of a product is higher, and the content of impure protein is lower; and the application security is greatly improved. Compared with the traditional low-temperature ethanol precipitation process, the canine immunoglobulin yield loss caused by precipitation, deep filtration and dissolution processes is reduced, and 100-1000L of plasma raw material can be treated on the chromatography scale of 100L of medium, so that the method can be completely amplified toactual production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Integrated crushing device for medical use

ActiveCN108212468AAchieve coolingImprove friendlinessDispersed particle filtrationMultistage water/sewage treatmentWastewaterPollution

The invention relates to an integrated crushing device for medical use. The integrated crushing device for the medical use comprises a crushing chamber, a solid-liquid separating chamber, a grinding chamber, a solid-gas separating chamber and a recycled water treatment chamber. Through detailed design of specific arrangement modes of the crushing chamber, the solid-liquid separating chamber, the grinding chamber and the solid-gas separating chamber, the production efficiency and the quantity of a finished product is guaranteed not to be lost in a medicament crushing process. Through specific arrangement of the recycled water treatment chamber, wastewater produced in a production process is recycled and reutilized, so that zero pollution in a production process is really realized.

Owner:应剑军

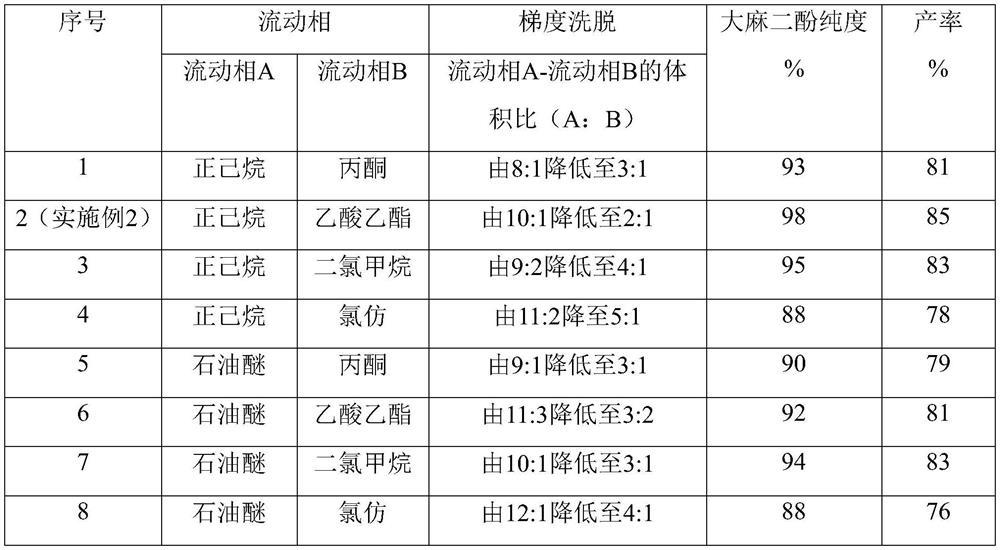

Method for preparing cannabidiol

ActiveCN111978156AEasy to separateShort separation cycleOrganic chemistryOrganic compound preparationOrganosolvCannabidiol

The invention relates to a method for preparing cannabidiol. The method comprises the following steps: separating a sample solution containing cannabidiol by adopting supercritical fluid chromatography to obtain high-purity cannabidiol, wherein a mobile phase in the supercritical fluid chromatography is supercritical carbon dioxide added with a modifier. According to the method, the high-purity cannabidiol can be efficiently and simply separated, the content of a main impurity, namely, cannabidiol, can be remarkably reduced, the purity of the cannabidiol is up to 97.59% to 99.89%, the sample loading amount is large, the separation period is short, the comprehensive yield is remarkably increased, and the organic solvent residue is low; and meanwhile, the method is suitable for separation and purification of various samples containing cannabidiol, is also suitable for industrial large-scale production and has a very wide application range.

Owner:YUNNAN HEMPMON PHARMA CO LTD

Gradient elution based method for continuously separating boron-enriched isotope through ion exchange chromatography

ActiveCN107261846AReduce formationImprove securityIsotope separationBoron-oxygen compoundsSimulated moving bedStrong acids

The invention discloses a gradient elution based method for continuously separating boron-enriched isotope through ion exchange chromatography. The method comprises the following steps: (1) feeding materials, namely, pumping a boric acid aqueous solution into a chromatographic column for ion exchange chromatography, wherein the chromatographic column is loaded on a simulated moving bed; performing material feeding adsorbing on the chromatographic column; (2) gradient eluting, namely, pumping an eluting solution into the chromatographic column, and then performing gradient eluting on the chromatographic column; and (3), collecting, namely, collecting a 10B acid solution from a lower end outlet of the chromatographic column; and evaporating and concentrating to obtain a 10B acid solid product, wherein the eluting solution for gradient eluting in step (2) is strong acid aqueous solution of which concentration continuously varies from 0 to 1 mol / L. According to the method, the strong acid aqueous solution of which the concentration continuously varies is used as the eluting solution on the simulated moving bed device, so that the enhanced separating of boron isotope is achieved; the separating capability of ion exchange chromatography is improved; the separating flow rate is increased; the separating cycle is reduced; and the abundance and the yield of the 10B acid solid product are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Washing machine used for summer squashes

PendingCN110871193AEasy to separateShort separation cycleCleaning using toolsCleaning using liquidsElectric machineryEnvironmental engineering

The invention relates to a washing machine used for summer squashes. The washing machine comprises a stirring tank, a PLC and an ozone generator connected with the stirring tank. A stirring motor anda water inlet pipe are arranged on the upper end portion of a tank body of the stirring tank, and the bottom of the tank body of the stirring tank is of a cambered surface structure and is connected with a material mixing pipe. The output end of the stirring motor is connected with a stirring shaft. Stirring blades are connected to the stirring shaft. Brushes are arranged on the inner wall of thestirring tank in the circumferential direction. An overflow tank is connected to the portion, close to the upper end portion, of the wall of the tank body. A first liquid level sensor is arranged on the portion, corresponding to the inner portion of the stirring tank, of the upper end of the overflow tank. The tail end of the material mixing pipe is connected with a material mixing pump. A discharge port of the material mixing pump is connected with a water draining tank. A water collection tank is arranged under the water draining tank. A second liquid level sensor is arranged in the water collection tank, and the outer end of the bottom of the water collection tank is connected with a circulating pump. The output end of the circulating pump is connected with a circulating pipeline. The tail end of the circulating pipeline communicates with the water inlet pipe. By means of the washing machine, the washing effect and efficiency are improved, the automation degree is high, and labor issaved.

Owner:酒泉凯地农业科技开发有限公司

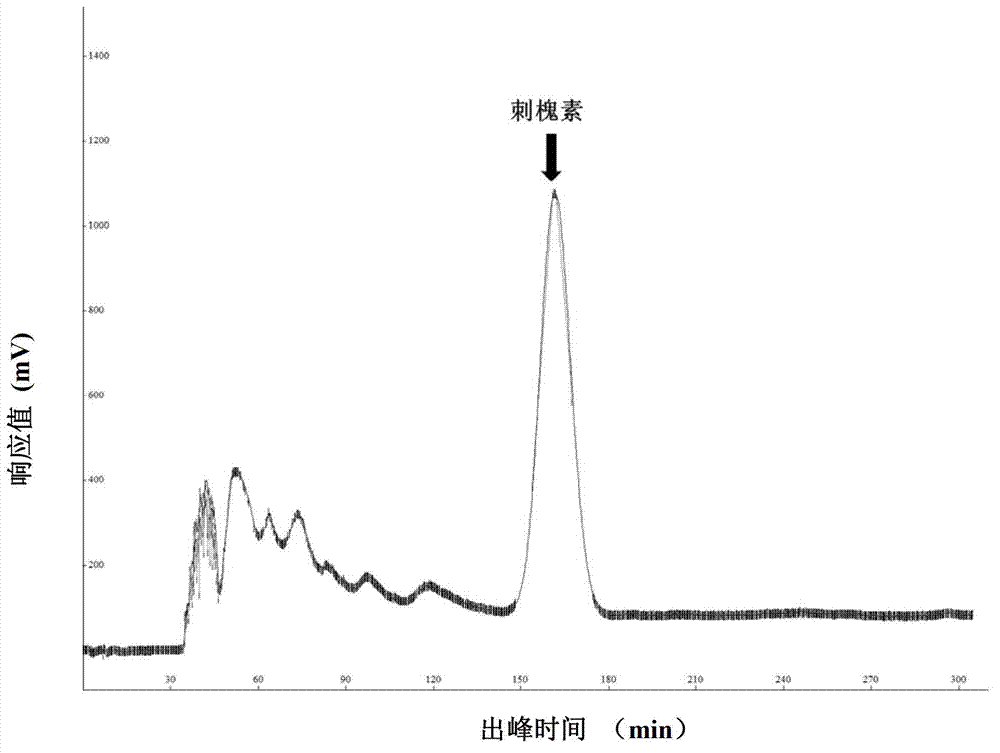

MPLC (medium-pressure liquid chromatography) separation and purification method for koumine

InactiveCN107987087ASimple and fast operationShort separation cycleOrganic chemistryPurification methodsEvaporation

The invention discloses an MPLC (medium-pressure liquid chromatography) separation and purification method for koumine. The method is characterized by comprising the following steps: 1) preparing a loading solution and an elution solvent system; 2) filling a chromatographic column with filler; 3) adding the loading solution, performing gradient elution, collecting eluates of corresponding absorption peaks according to appearance time, detecting the eluates with high-performance liquid chromatography, combining the eluates containing the koumine, and performing reduced-pressure evaporation andethanol recrystallization to obtain a koumine monomer. The loading solution is prepared through the following steps: total gelsemium alkaloids or low-purity koumine are or is dissolved in an organic solvent, and a sample solution is filtered by an organic filter membrane. The filler of the chromatographic column is normal-phase or reverse-phase silica gel filler. Compared with the traditional column chromatography and high-speed counter-current methods, the separation and purification method for the koumine has the advantages of being simple and convenient to operate and good in controllability. Medium-pressure preparative chromatographs with different specifications can be selected for separation, the preparation amount can reach hectogram scale, and industrial manufacture requirements can be met.

Owner:FUJIAN MEDICAL UNIV

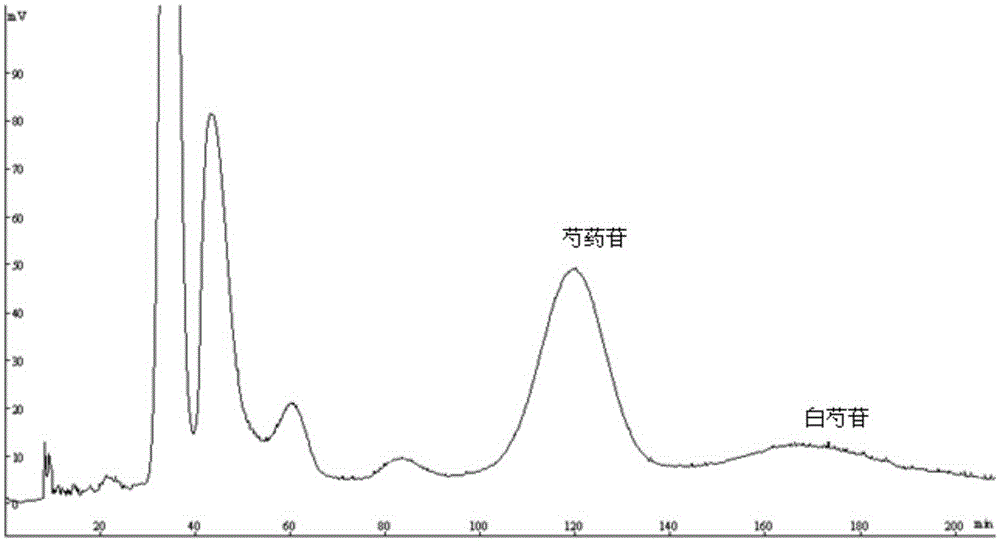

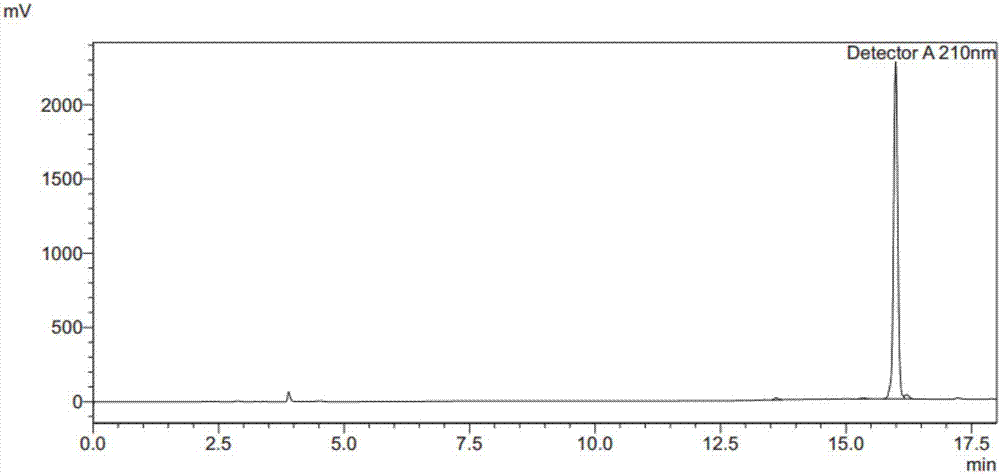

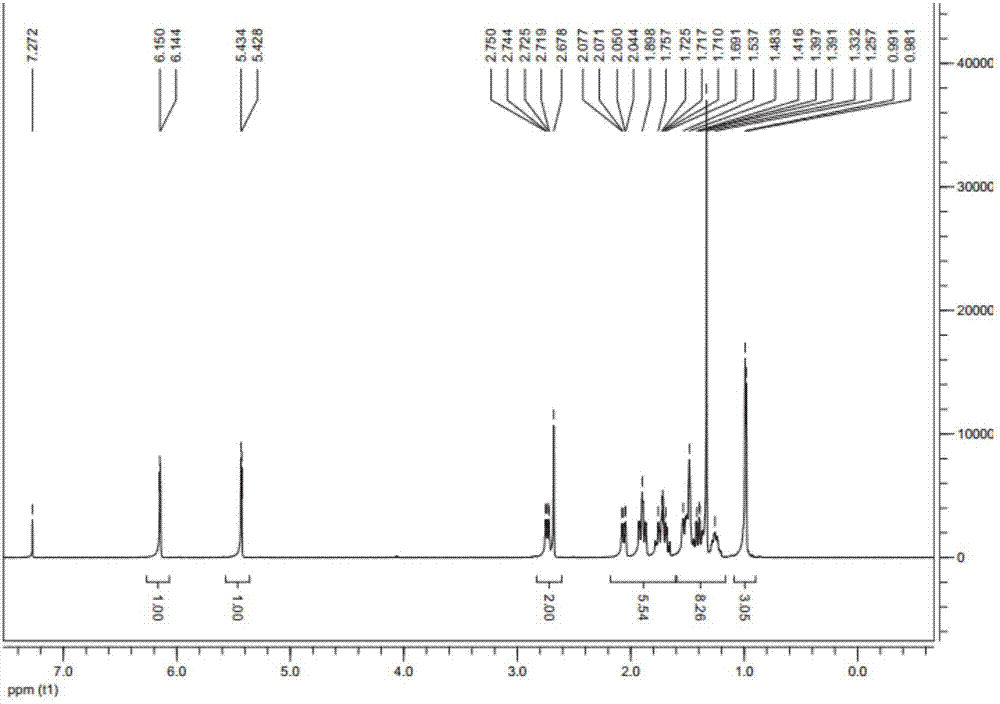

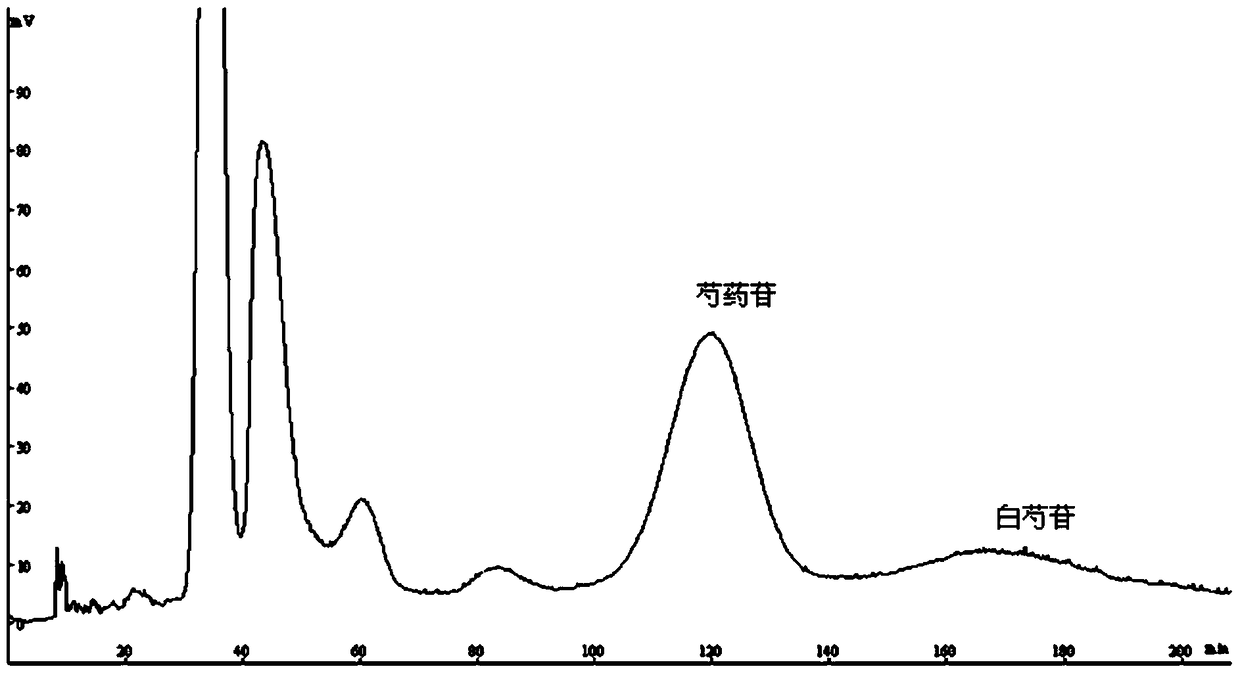

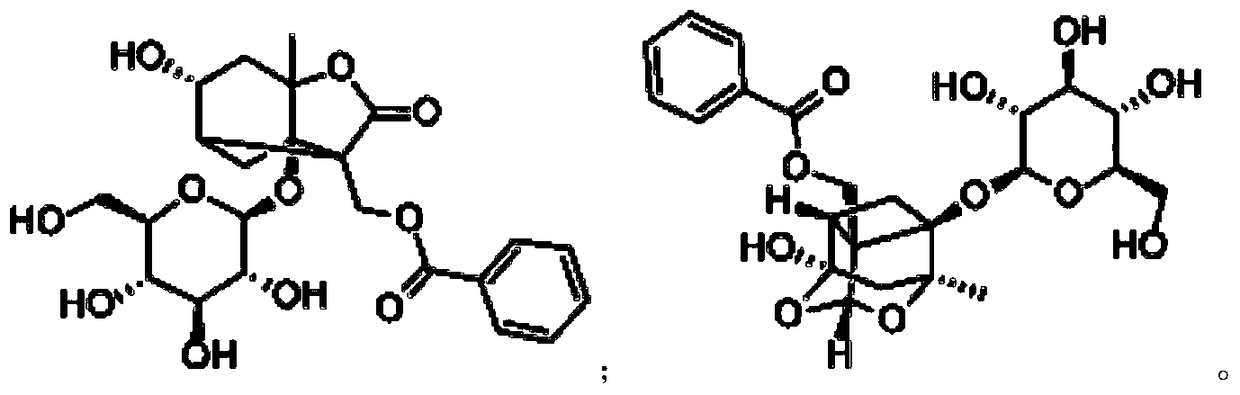

Preparation method of high-purity paeoniflorin and albiflorin

ActiveCN105273015AHigh purityIncrease production capacitySugar derivativesSugar derivatives preparationUltraviolet detectorsCountercurrent chromatography

The invention relates to a preparation method of high-purity paeoniflorin and albiflorin. The method includes the steps of firstly, adding smashed paeoniaceae plant raw materials containing paeoniflorin and albiflorin to an ethanol solution, conducting ultrasonic extraction, concentrating an extracting solution to obtain extract, dissolving extract with water, and conducting extraction and pressure reduction concentration to obtain extract; secondly, eluting extract with an alcohol-water solution through column chromatography with macroporous resin as filler, collecting flow components containing paeoniflorin and albiflorin, and conducting concentrating and drying to obtain coarse extract; thirdly, separating out the coarse extract through a high-speed countercurrent chromatography method, conducting online monitoring through an ultraviolet detector, collecting flow components and pressure reduction concentration, and conducting crystallizing and drying to obtain paeoniflorin and albiflorin, wherein a solvent system of the high-speed countercurrent chromatography is prepared from carbon trichloride, butyl alcohol, methyl alcohol and water. Paeoniflorin and albiflorin prepared through the method are high in product purity and good in quality, are suitable for high-speed countercurrent chromatographs of various types and can be easily and industrially amplified.

Owner:SHANGHAI TAUTO BIOTECH CO LTD

Method for preparing high-purity cannabidiol by combining macroporous resin enrichment with dynamic axial compression column system

PendingCN111848358AAddressing Purity IssuesResolution timeOrganic chemistryOrganic compound preparationPhysical chemistryGradient elution

The invention discloses a method for preparing high-purity cannabidiol by combining macroporous resin enrichment with a dynamic axial compression column system, and belongs to the technical field of natural medicine preparation. The method comprises the following steps: drying floccules and leaves of industrial hemp, crushing and sieving; obtaining industrial hemp powder, heating, refluxing and extracting to prepare an upper column solution; passing through a macroporous adsorption resin chromatographic column; performing post-water elution, recovering the solvent from the eluent, concentrating to obtain a cannabidiol primary extract, adding methanol and crude silica gel, uniformly stirring, drying to obtain a loading sample, treating the loading sample by using a dynamic axial compressioncolumn system, carrying out gradient elution by using a mobile phase, concentrating the eluent, filtering, recovering the mobile phase solvent, and drying to obtain cannabidiol crystals. The method has the advantages of high yield, high cannabidiol purity and short extraction time, solves the problems of low production efficiency, low purity and long extraction time in the existing cannabidiol extraction technology, and is suitable for industrial extraction of cannabidiol.

Owner:黑龙江阳光工业大麻研究院

Method for extracting arteannuin B from herba artemisiae annuae

ActiveCN107383043AShort separation cycleReduce separation costsOrganic chemistrySolventChromatographic column

The invention discloses a method for extracting arteannuin B from herba artemisiae annuae. The method comprises the following steps: after crushing the herba artemisiae annuae, immersing the herba artemisiae annuae with methanol to obtain an immersing solution; then carrying out crude separation through a macroporous resin column, carrying out secondary separation through a polyamide adsorption resin chromatographic column, carrying out sephadex chromatographic column separation and carrying out high performance liquid chromatographic column separation in sequence. The method disclosed by the invention has a short separation period and used solvents only comprise methanol and pure water; most of solvents and separation columns can be repeatedly utilized so that the separation cost is saved; meanwhile, the method is safe to operate and is environmentally friendly. Meanwhile, the purity of the separated arteannuin B can reach 98 percent or more and scopoletin impurities can be removed. By adopting the method disclosed by the invention, the arteannuin B with high purity is effectively extracted from the herba artemisiae annuae and the extraction efficiency is high, so that the method is suitable for large-scale production and has very strong industrial practicability.

Owner:武汉天植生物技术有限公司

A kind of preparation method of high-purity paeoniflorin and paeoniflorin

ActiveCN105273015BHigh purityIncrease production capacitySugar derivativesSugar derivatives preparationCountercurrent chromatographyAlcohol

The invention relates to a preparation method of high-purity paeoniflorin and albiflorin. The method includes the steps of firstly, adding smashed paeoniaceae plant raw materials containing paeoniflorin and albiflorin to an ethanol solution, conducting ultrasonic extraction, concentrating an extracting solution to obtain extract, dissolving extract with water, and conducting extraction and pressure reduction concentration to obtain extract; secondly, eluting extract with an alcohol-water solution through column chromatography with macroporous resin as filler, collecting flow components containing paeoniflorin and albiflorin, and conducting concentrating and drying to obtain coarse extract; thirdly, separating out the coarse extract through a high-speed countercurrent chromatography method, conducting online monitoring through an ultraviolet detector, collecting flow components and pressure reduction concentration, and conducting crystallizing and drying to obtain paeoniflorin and albiflorin, wherein a solvent system of the high-speed countercurrent chromatography is prepared from carbon trichloride, butyl alcohol, methyl alcohol and water. Paeoniflorin and albiflorin prepared through the method are high in product purity and good in quality, are suitable for high-speed countercurrent chromatographs of various types and can be easily and industrially amplified.

Owner:SHANGHAI TAUTO BIOTECH CO LTD

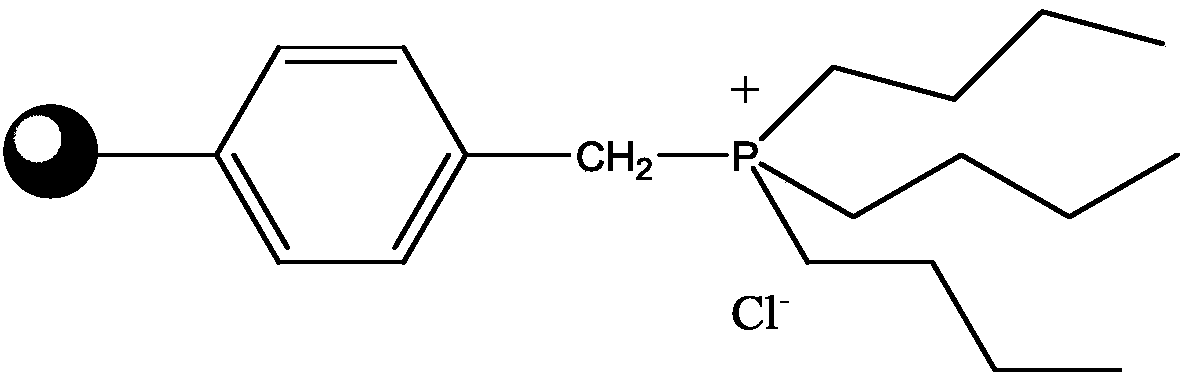

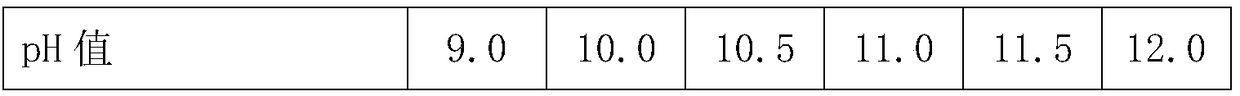

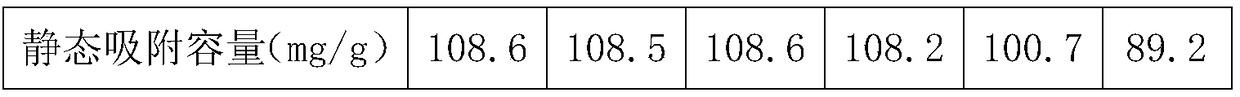

Method for separating platinum and rhodium from alkaline cyanide solution by using polystyrene-tributyl quaternary phosphonium resin

ActiveCN109385525AShort separation cycleLarge adsorption capacityProcess efficiency improvementPhosphoniumCyanide

The invention discloses a method for separating platinum and rhodium from an alkaline cyanide solution by using polystyrene-tributyl quaternary phosphonium resin (PS-BQP for short), and belongs to thetechnical field of platinum group metal separation. The method comprises the following steps: by taking the PS-BQP as an adsorbent, jointly adsorbing Pt(CN)42<-> and Rh(CN)63<-> in an alkaline cyanide solution medium with a pH being equal to 9.0 to 11.0 and at a solid-liquid ratio being 1:100 (g / mL); performing step-by-step elution on the adsorbed Pt(CN)42<-> and Rh(CN)63<-> according to a two-step elution method: firstly, using a KCI solution at a concentration of 0.5 to 1 mol / L to desorb the Rh(CN)63<-> adsorbed on the PS-BQP and then using an NH4SCN solution at a concentration of 1.0 to 1.5 mol / L to desorb the Pt(CN)42<-> adsorbed on PS-BQP, thereby achieving separation of the Pt(CN)42<-> and the Rh(CN)63<->. The method is simple in operation flow and short in separation period; the recovery rate of platinum is higher than 96.0%, and the recovery rate of ruthenium is higher than 95.0%; the adsorption capacity of the PS-BQP adsorbent is high, and the stability is good; the PS-BQP adsorbent can be repeatedly used after being regenerated by the saturated KCl solution.

Owner:YUNNAN UNIV

Method for separating and purifying quercetin tagetin from marigold

ActiveCN105693676BWide variety of sourcesHigh degree of automationOrganic chemistryMethanol waterIsocratic elution

The invention provides a method for separating and purifying quercetin tagetin from marigolds, which comprises the following steps: drying the dried flowers of marigolds and grinding them into powder, soaking them in ethanol or extracting them under reflux, rotating the filtered filtrate to dryness, and dissolving In a mixed solvent of methanol-water; perform one-dimensional liquid chromatography: use DAISO C18 as a chromatographic column, phase A water and phase B methanol as mobile phase, phase B concentration 50-55% isocratic elution for 20min, according to the ultraviolet absorption spectrum Collect the eluate after 6-12 minutes as the target component, and then dissolve it in methanol-water mixed solvent after rotary evaporation to dryness; carry out two-dimensional liquid chromatography: use Acchrom X-Amide as the chromatographic column, A phase water, B phase acetonitrile It is the mobile phase, and the B phase concentration is 92-98% and isocratic elution for 40 minutes. According to the ultraviolet absorption spectrum, the 27-33-minute eluate is collected as the target component, and the quercetin-tagoldin with a purity of more than 99% is obtained by rotary evaporation to dryness. .

Owner:TIANJIN YAOYU BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com