Method for preparing high-purity cannabidiol by combining macroporous resin enrichment with dynamic axial compression column system

A technology of axial compression and macroporous resin, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of long extraction time, low purity, low yield, etc., and achieve short separation cycle, reduce Environmental pollution, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

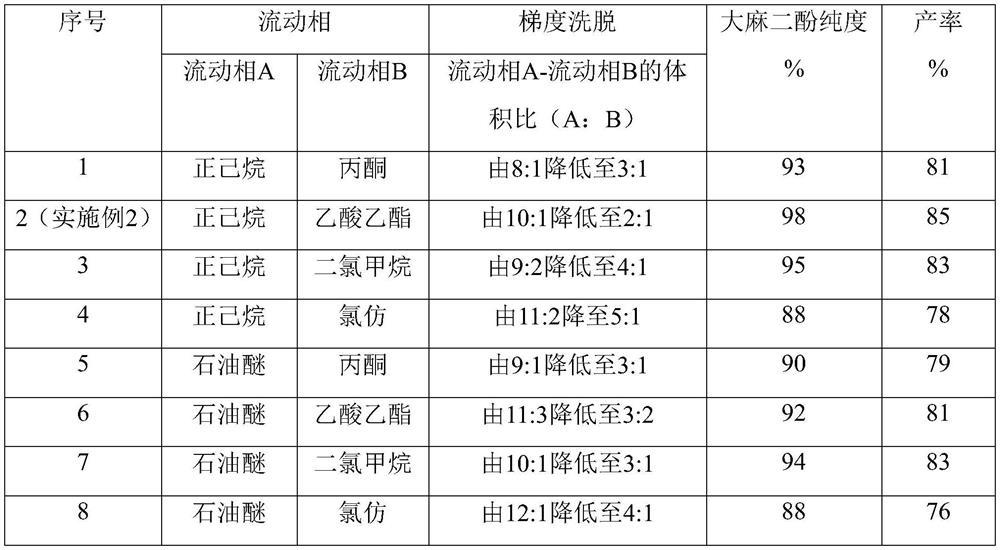

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing high-purity cannabidiol by enriching a macroporous resin combined with a dynamic axial compression column system. The method is carried out according to the following steps:

[0035] Step 1: drying the tidbits and leaves of industrial hemp at 55°C for 8 hours until the water content is between 3% and 5%, crushing and passing through a 100-mesh sieve to obtain industrial hemp powder;

[0036] Step 2: Add 20 times the volume of 75% (volume percent concentration) ethanol solution to the industrial hemp powder, heat and reflux for extraction 3 times, each time for 1.5 hours, combine the extracts, centrifuge or filter, and recover the extraction solvent under reduced pressure. Carry out double-effect concentration, after concentration, adjust the pH value to 5.0-6.0 to get the column solution, pass the column solution through the macroporous adsorption resin chromatography column at a flow rate of 2BV / h, and the column solution ...

Embodiment 2

[0040] This embodiment provides a method for preparing high-purity cannabidiol by enriching a macroporous resin combined with a dynamic axial compression column system. The method is carried out according to the following steps:

[0041] Step 1: drying the tidbits and leaves of industrial hemp at 60°C for 6 hours until the water content is between 3% and 5%, crushing them and passing them through an 80-mesh sieve to obtain industrial hemp powder;

[0042] Step 2: Add 16 times the volume of 50% (volume percent concentration) methanol solution to the industrial hemp powder, heat and reflux for extraction 3 times, each time for 2 hours, combine the extracts, then concentrate after centrifugation or filtration, and adjust the pH after concentration When the value reaches 4.0-5.0, the column solution is obtained. Pass the column solution through the macroporous adsorption resin chromatography column at a flow rate of 3BV / h, and the column solution is 1:10 according to the ratio of s...

Embodiment 3

[0049] This embodiment provides a method for preparing high-purity cannabidiol by enriching a macroporous resin combined with a dynamic axial compression column system. The method is carried out according to the following steps:

[0050] Step 1: drying the tidbits and leaves of industrial hemp at 70°C for 6 hours until the water content is between 3% and 5%, crushing and passing through a 60-mesh sieve to obtain industrial hemp powder;

[0051] Step 2: Add 12 times the volume of 80% (volume) methanol solution to the industrial hemp powder, heat and reflux for extraction twice, each time for 3 hours, combine the extracts, filter the obtained filtrate to recover the extraction solvent under reduced pressure, adjust after concentration When the pH value reaches 6.8, the column solution is obtained, and the column solution is passed through the macroporous adsorption resin chromatography column at a flow rate of 2BV / h, and the column solution is 1:9 according to the ratio of solids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com