Continuous gradient elution system based on stimulated moving bed and treatment method of continuous gradient elution system

A technology for simulating moving bed and elution system, which is applied in the field of chemical and chemical separation, and can solve problems such as unavailable supply, long separation cycle, and small single-stage separation factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

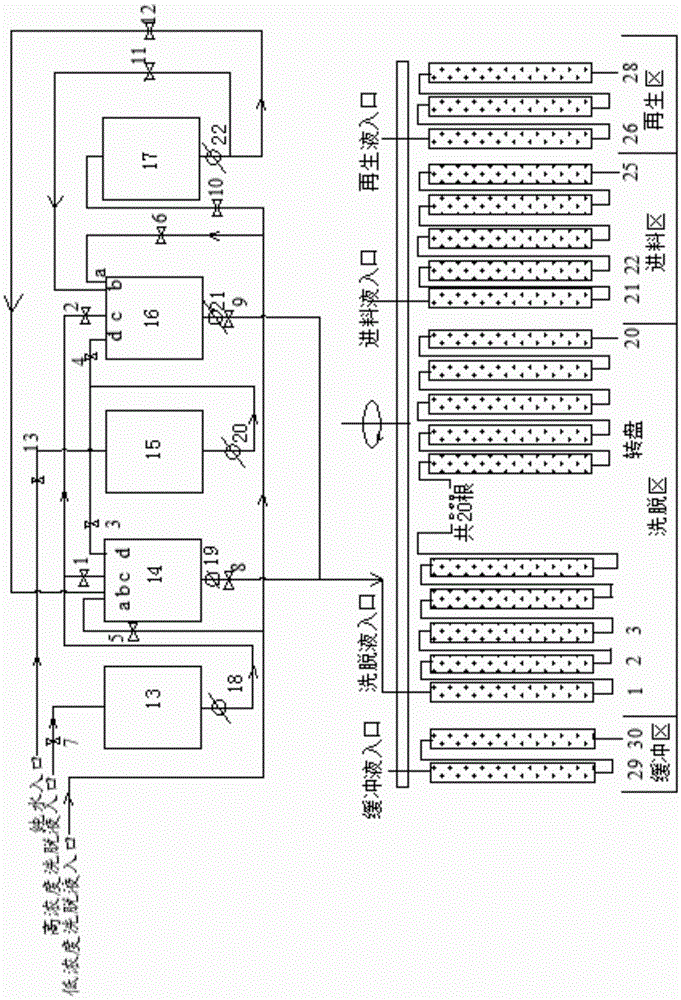

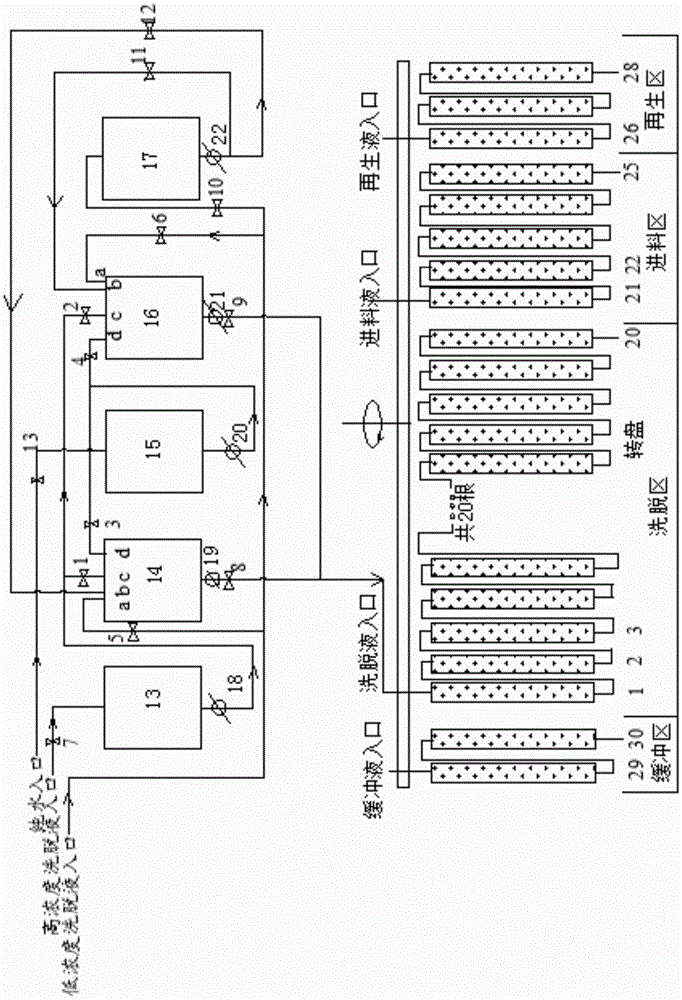

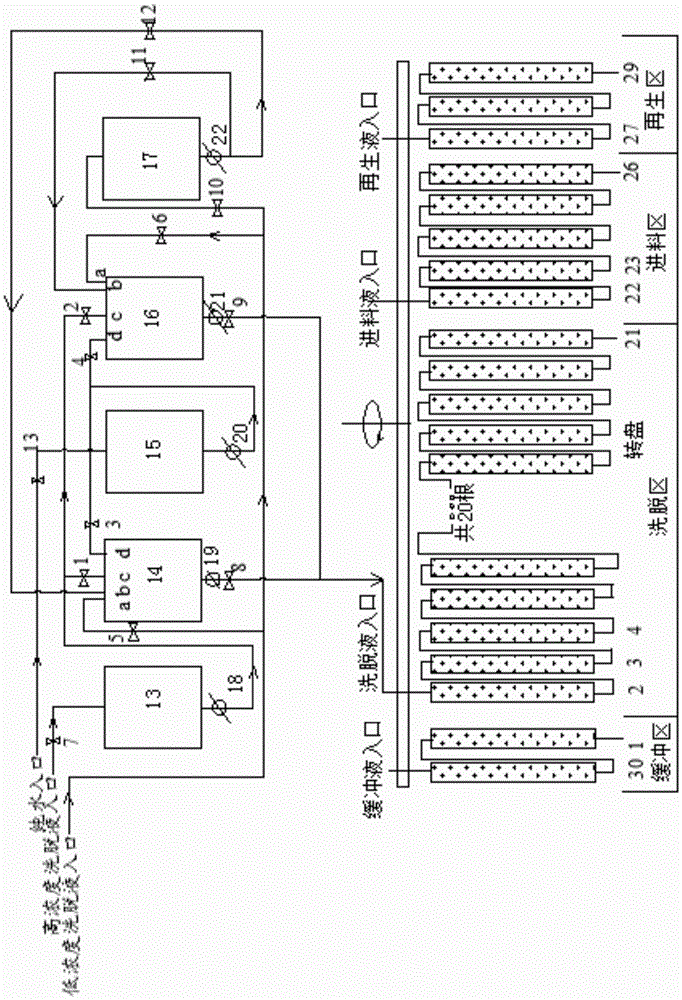

[0065] Such as figure 1 As shown, this embodiment provides a continuous gradient elution system based on a simulated moving bed, and the system includes a simulated moving bed and an associated device connected to a single chromatographic column in the elution zone of the simulated moving bed. The supporting device comprises a first eluent storage tank 13, a second eluent storage tank 17, a pure water storage tank 15, a first eluent buffer tank 14 and a second eluent buffer tank 16, the first eluent The liquid outlet of the dehydration storage tank 13 is connected with the liquid inlets of the first eluent buffer tank 14 and the second eluent buffer tank 16 respectively through pipelines, and the liquid outlet of the pure water storage tank 15 is connected with the first eluent buffer tank 15 respectively. The liquid inlet of the eluent buffer tank 14 and the second eluent buffer tank 16 is connected by a pipeline, and the liquid outlet of the second eluent storage tank 17 is...

Embodiment 2

[0067] In this embodiment, the system described in Embodiment 1 is adopted, and the aqueous hydrochloric acid solution whose concentration increases linearly with time is used as the gradient eluent, and is combined with a simulated moving bed SMB device to realize boron isotope separation. First prepare two kinds of hydrochloric acid with different concentrations as the eluent of the experiment, wherein the hydrochloric acid with relatively high concentration is represented by eluent A, and the hydrochloric acid with relatively low concentration is represented by eluent B. The concentration of hydrochloric acid in eluent A is 1mol / L, and the concentration of hydrochloric acid in the initial state of eluent B is 0.1mol / L. Take 2F 1 =F 2 , the flow rate F of the eluent A 1 =15mL / min; flow rate F of eluent B 2 = 30 mL / min. Liquid flow F from the pure water storage tank 15 to the first eluent buffer tank 14 or the second eluent buffer tank 16 3 =30mL / min; the liquid flow F o...

Embodiment 3

[0070] In this embodiment, the system described in Embodiment 1 is adopted, and the aqueous hydrochloric acid solution whose concentration gradually increases in a concave curve with time is used as the gradient eluent, and a simulated moving bed device is used to realize boron isotope separation. First prepare two kinds of hydrochloric acid with different concentrations as the eluent of the experiment, wherein the hydrochloric acid with relatively high concentration is represented by eluent A, and the hydrochloric acid with relatively low concentration is represented by eluent B. The concentration of hydrochloric acid in eluent A is 1mol / L, and the concentration of hydrochloric acid in the initial state of eluent B is 0.1mol / L. Take 3F 1 =F 2 , the flow rate F of the eluent A 1 =10mL / min; flow rate F of eluent B 2 = 30 mL / min. Liquid flow F from the pure water storage tank 15 to the first eluent buffer tank 14 or the second eluent buffer tank 16 3 =30mL / min; the liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com