Gallium phosphide photocatalyst for photolysis of water to produce hydrogen and preparation method of gallium phosphide photocatalyst

A technology for photo-splitting water for hydrogen production and photocatalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc. Easy to obtain and improve the effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

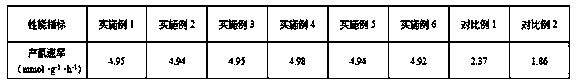

Examples

Embodiment 1

[0026] (1) Mechanically grind gallium phosphide particles into powder, ultrasonically disperse them in deionized water and let them stand for a certain period of time, take the supernatant, centrifuge and dry, continue to add the obtained powder into N,N-dimethylacetamide, ultrasonically After dispersing, let it stand for a certain period of time, take the supernatant and centrifuge and dry it to obtain micronized gallium phosphide powder; the time for ultrasonic dispersion in deionized water is 16 minutes, and the resting time is 70 minutes; in N,N-dimethylacetamide The time for ultrasonic dispersion is 36 minutes, and the standing time is 130 minutes;

[0027] (2) Disperse the micronized gallium phosphide powder and electron acceptor compound prepared in step (1) in absolute ethanol, transfer them to a high-energy ball mill for mixed ball milling, and obtain a mixed dispersion; the electron acceptor compound is iron Potassium cyanide; the rotating speed of the ball mill is 6...

Embodiment 2

[0030] (1) Mechanically grind gallium phosphide particles into powder, ultrasonically disperse them in deionized water and let them stand for a certain period of time, take the supernatant, centrifuge and dry, continue to add the obtained powder into N,N-dimethylacetamide, ultrasonically After dispersing, let it stand for a certain period of time, take the supernatant and centrifuge and dry it to obtain micronized gallium phosphide powder; the time for ultrasonic dispersion in deionized water is 12 minutes, and the resting time is 80 minutes; in N,N-dimethylacetamide The time of ultrasonic dispersion is 32min, and the standing time is 130min;

[0031] (2) Disperse the micronized gallium phosphide powder and electron acceptor compound prepared in step (1) in absolute ethanol, transfer them to a high-energy ball mill for mixed ball milling, and obtain a mixed dispersion liquid; the electron acceptor compound is heavy Potassium chromate; the rotational speed of the ball mill is 6...

Embodiment 3

[0034] (1) Mechanically grind gallium phosphide particles into powder, ultrasonically disperse them in deionized water and let them stand for a certain period of time, take the supernatant, centrifuge and dry, continue to add the obtained powder into N,N-dimethylacetamide, ultrasonically After dispersion, stand for a certain period of time, take the supernatant and centrifuge and dry to obtain micronized gallium phosphide powder; the time for ultrasonic dispersion in deionized water is 18 minutes, and the standing time is 80 minutes; in N,N-dimethylacetamide The time of ultrasonic dispersion is 38min, and the standing time is 140min;

[0035] (2) Disperse the micronized gallium phosphide powder and electron acceptor compound prepared in step (1) in absolute ethanol, transfer them to a high-energy ball mill for mixed ball milling, and obtain a mixed dispersion liquid; the electron acceptor compound is high Potassium manganate; the rotational speed of the ball mill is 750r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com