Row-type gathering blowing duct for the drafting area of the traveling cleaning system of the roving frame

A blowing pipe and cleaning system technology, applied in textiles and papermaking, etc., can solve the problems of large air volume loss, flying flower spreading, orientation of flying flower in the drafting area, and unsatisfactory collection effect of gathering and gathering, so as to reduce the loss of air outlet air volume , ideal blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

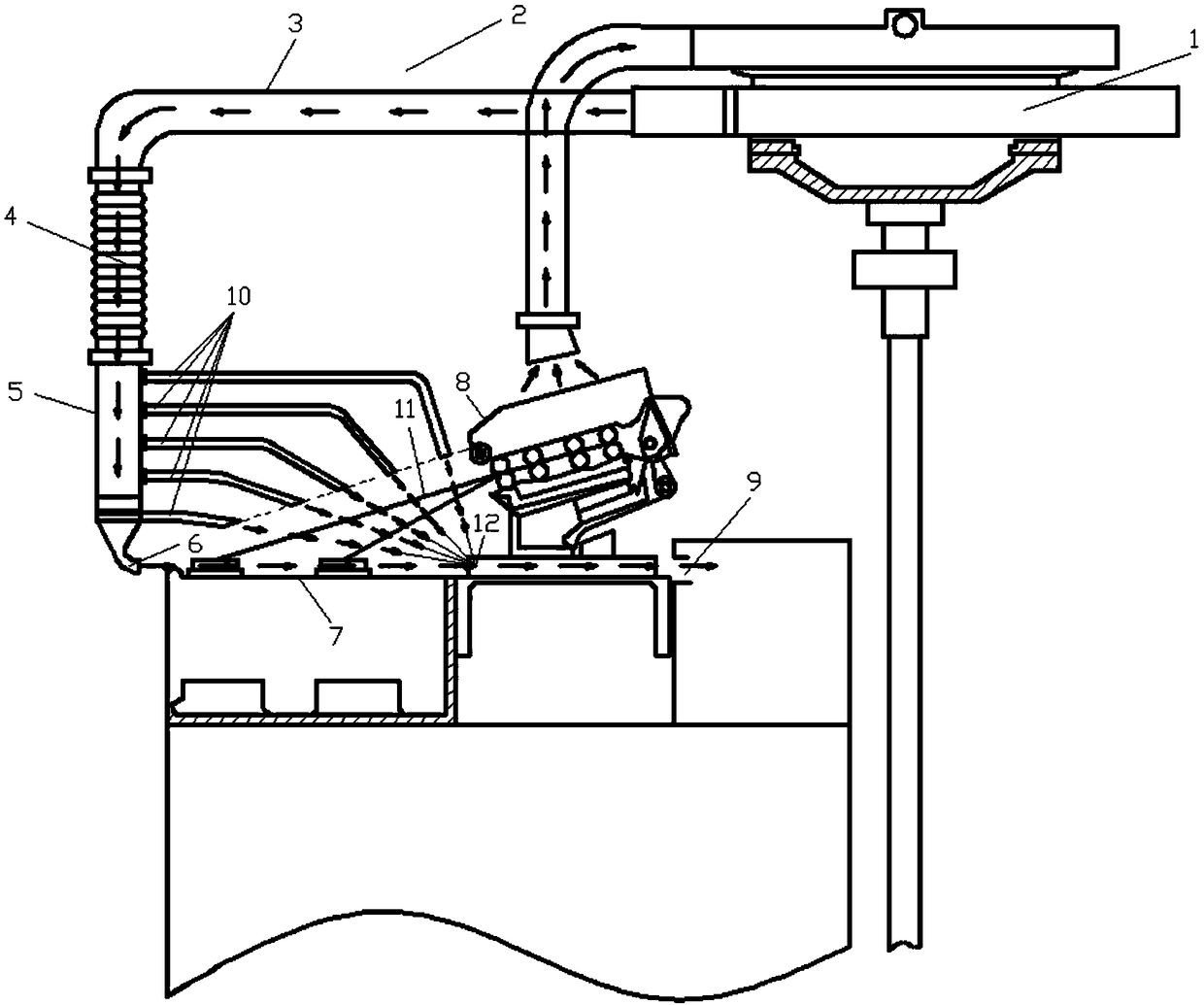

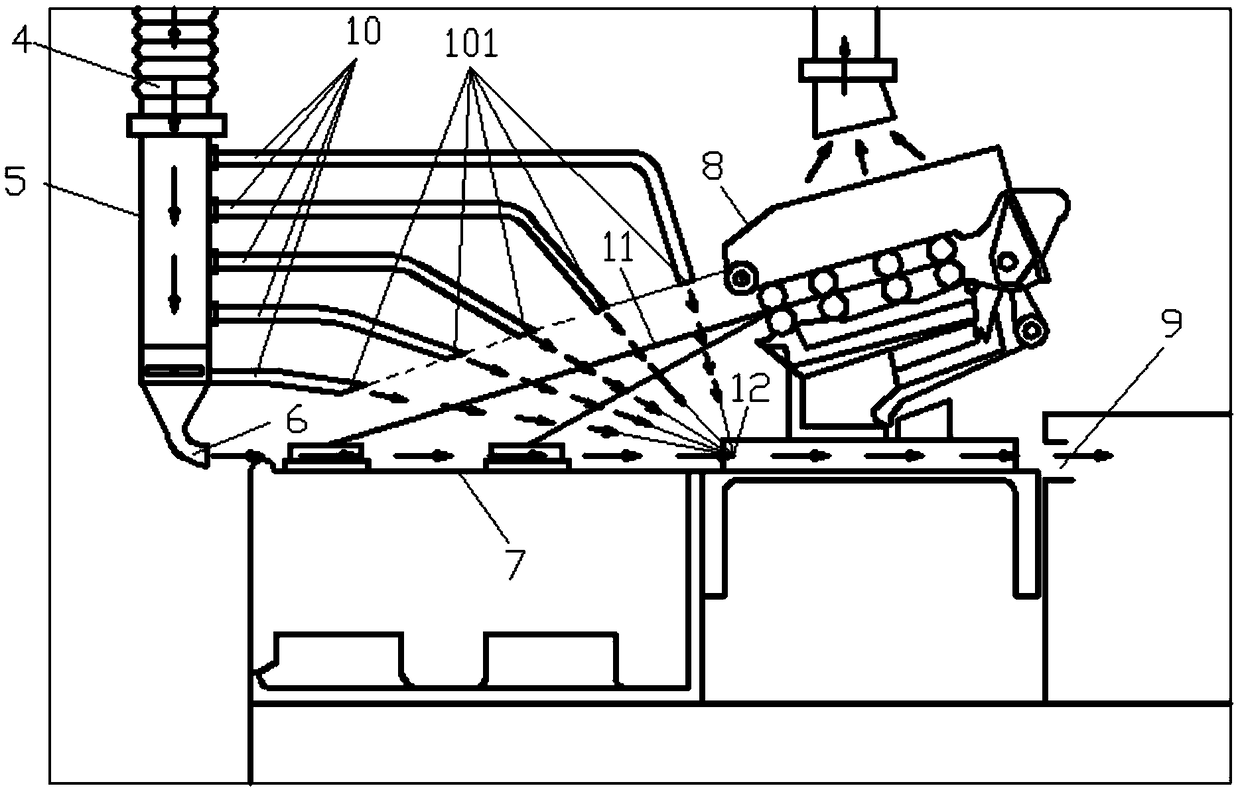

[0017] Attached below Figure 1-2 An embodiment of the present invention is described.

[0018] Row-type gathering blowing ducts for the drafting area of the traveling cleaning system of the roving frame, (e.g. figure 1 As shown) includes a blowing duct 2 connected to the air outlet of the itinerant cleaner 1, and the blowing duct 2 consists of an upper "L"-shaped rigid section 3, a middle vertical telescopic section 4 and a lower vertical rigid section 5 The vertical telescopic section 4 in the middle is used to adjust the longitudinal extension distance of the blowing duct 2. The upper "L"-shaped rigid section 3 and the lower vertical rigid section 5 are used to install each branch blowing pipeline. The lower end of the vertical rigid section 5 is provided with a flat square blowing nozzle I6 which is convenient for directional air supply and increases the wind pressure. The flat square blowing nozzle I6 is facing the roving locomotive table 7 and blowing horizontally, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com