A circuit board cutting equipment based on dust absorption principle

A dust absorption and cutting equipment technology, applied in metal processing and other directions, can solve the problems of high temperature, humidity and dust requirements, and the influence of circuit board use, so as to achieve better blowing effect, improve filtering effect, and increase flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

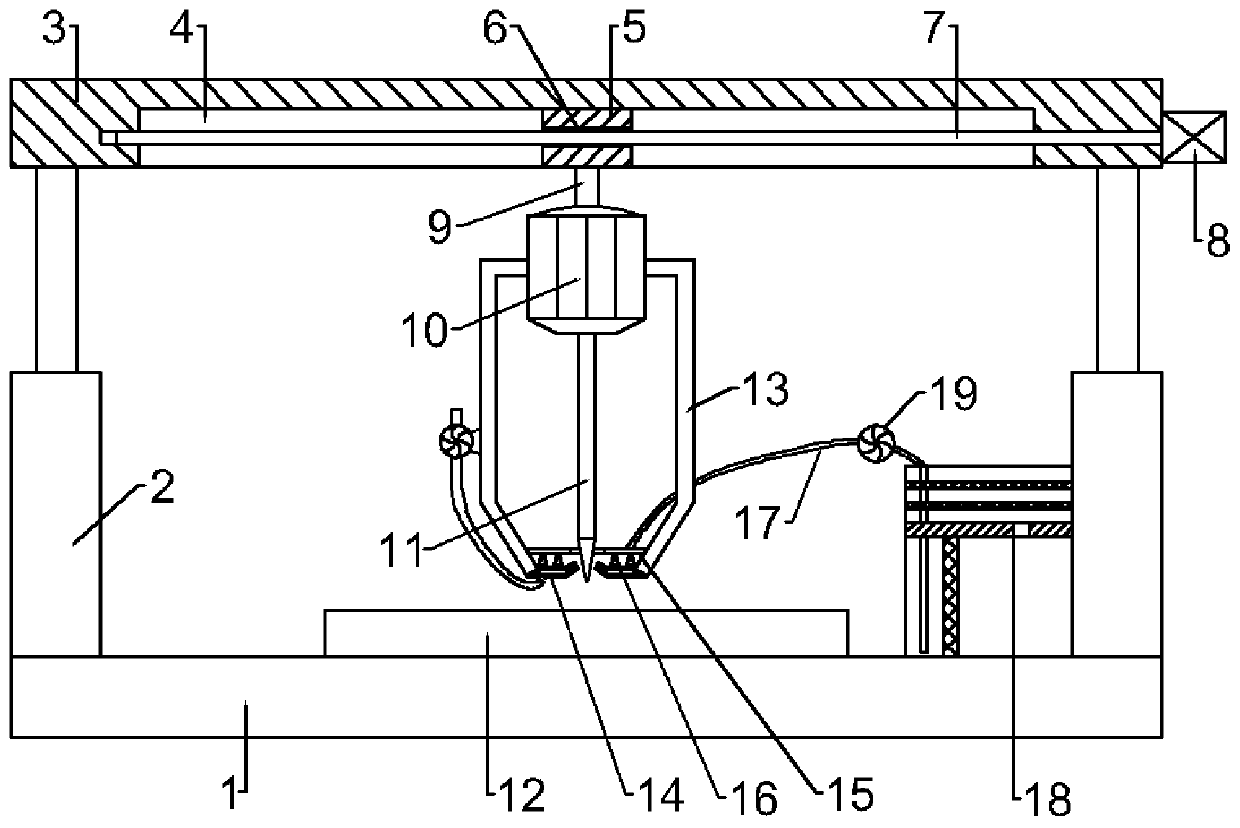

[0024] see figure 1 , in an embodiment of the present invention, a circuit board cutting device based on the principle of dust absorption, including a base plate 1, a circuit board 12 is placed on the base plate 1, two electric push rods 2 are fixedly connected to the left and right ends of the base plate 1, two The top of the electric push rod 2 is jointly fixedly connected with a top plate 3, and the top plate 3 is provided with a moving groove 4 with the opening facing downwards. A moving block 5 is arranged in the moving groove 4, and a threaded through hole 6 is provided on the moving block 5. The hole 6 is internally threaded with a threaded rod 7, the two ends of the threaded rod 7 are rotationally connected with the two ends of the moving groove 4, and the right end of the threaded rod 7 is fixedly connected with the output shaft of the motor 8, and the lower side of the moving block 5 is fixedly connected through the connecting column 9 Cutting motor 10 is arranged, a...

Embodiment 2

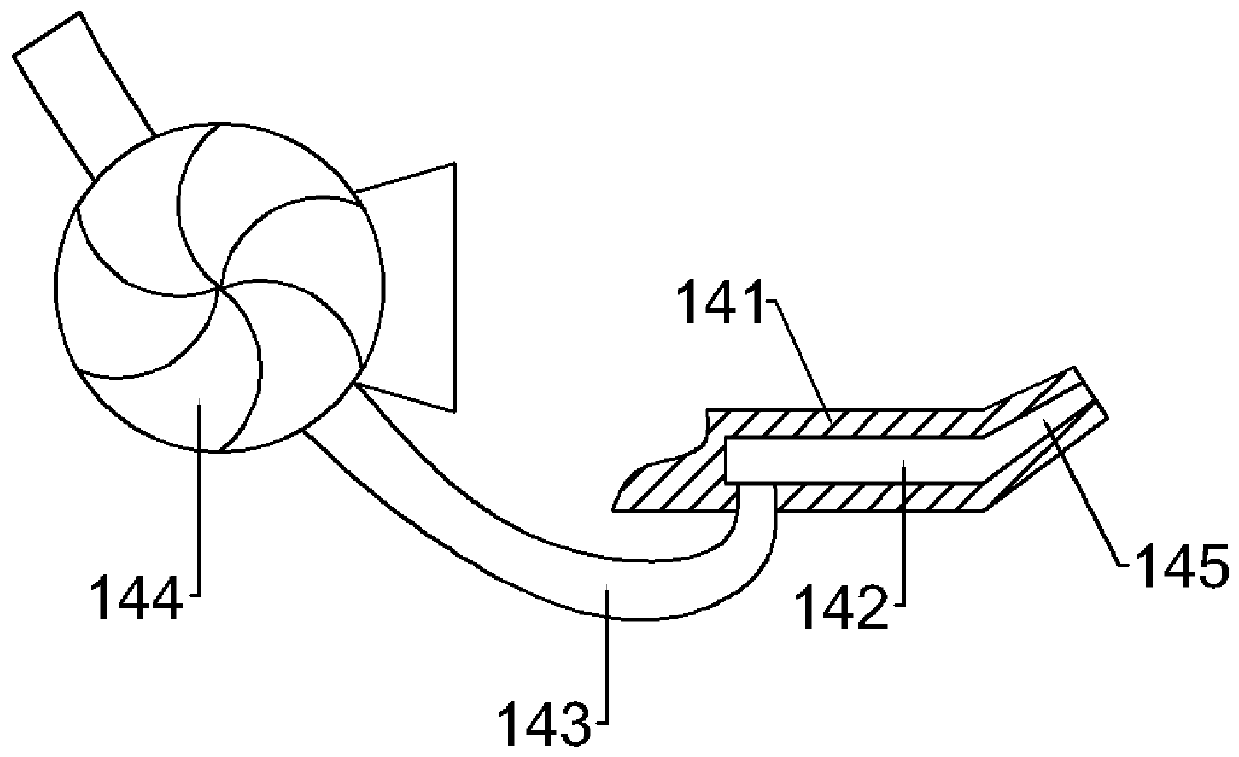

[0027] see figure 1 and figure 2 , the outer cover of the cutting motor 10 is provided with a protective cover 13, and the outer bottom of the protective cover 13 is provided with a blowing device 14, and the blowing device 14 includes an air distribution ring plate 141, and the air distribution ring plate 141 is fixedly connected with the bottom end of the protective cover 13 , and the inside of the air distribution ring plate 141 is provided with an air distribution cavity 142, the air distribution cavity 142 is connected to the blower 144 on the outer wall of the protective cover 13 through the first hose 143, and the inner side of the air distribution ring plate 141 is fixedly connected There is a raised part 145, which will produce a little dust during cutting. At this time, start the blower 144, and the blower 144 will blow the outside air into the air distribution chamber 142 through the first hose 143, and then spray it out through the raised part 145, so that The du...

Embodiment 3

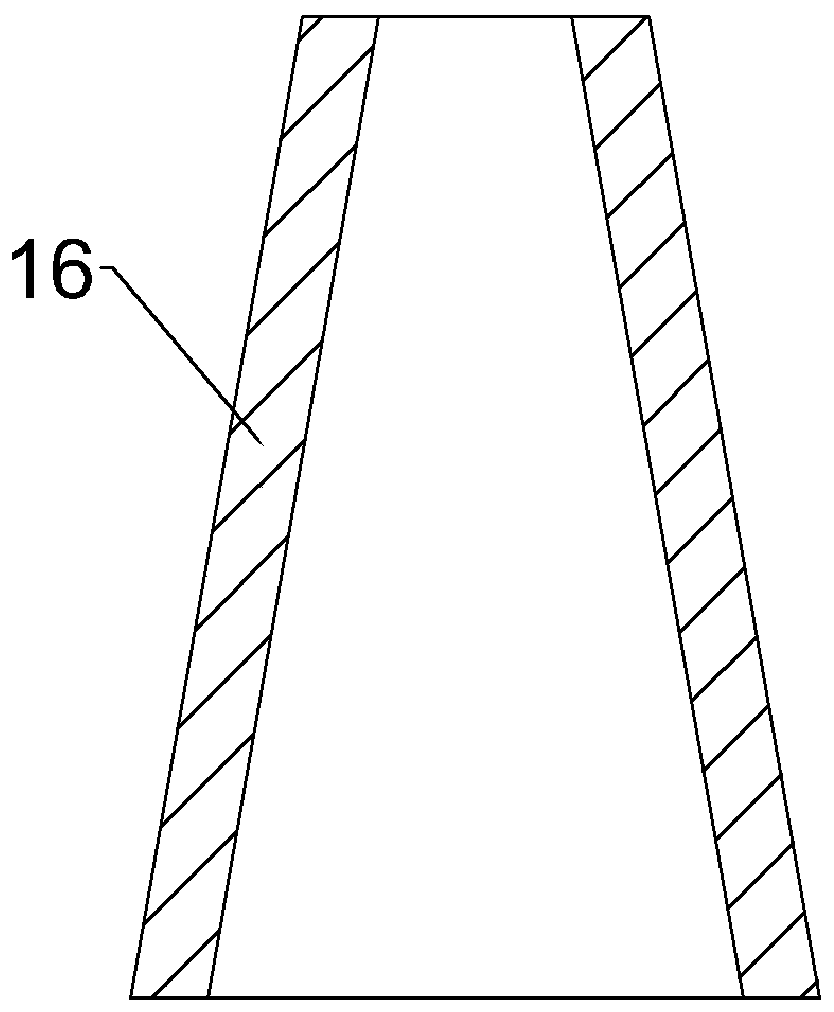

[0030] see figure 1 and image 3 , the inner bottom of the protective cover 13 is fixedly connected with an absorbing ring plate 15, and an absorbing cavity is opened inside the absorbing ring plate 15, and several absorbers 16 are evenly arranged on the lower side of the absorbing ring plate 15, and the cross section of the absorbing bodies 16 is It is in the shape of an isosceles trapezoid with a small top and a large bottom, and the absorber 16 communicates with the inside of the absorbing cavity. The absorbing ring plate 16 communicates with the absorbing device 18 on the bottom plate 1 through the second hose 17, and the second hose 17 is provided with an induced fan 19, and the induced fan 19 works to suck the dust entering the protective cover 13 into the absorption cavity through the absorber 16, and then enters the absorption device 18 through the second hose 17 to be absorbed;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com