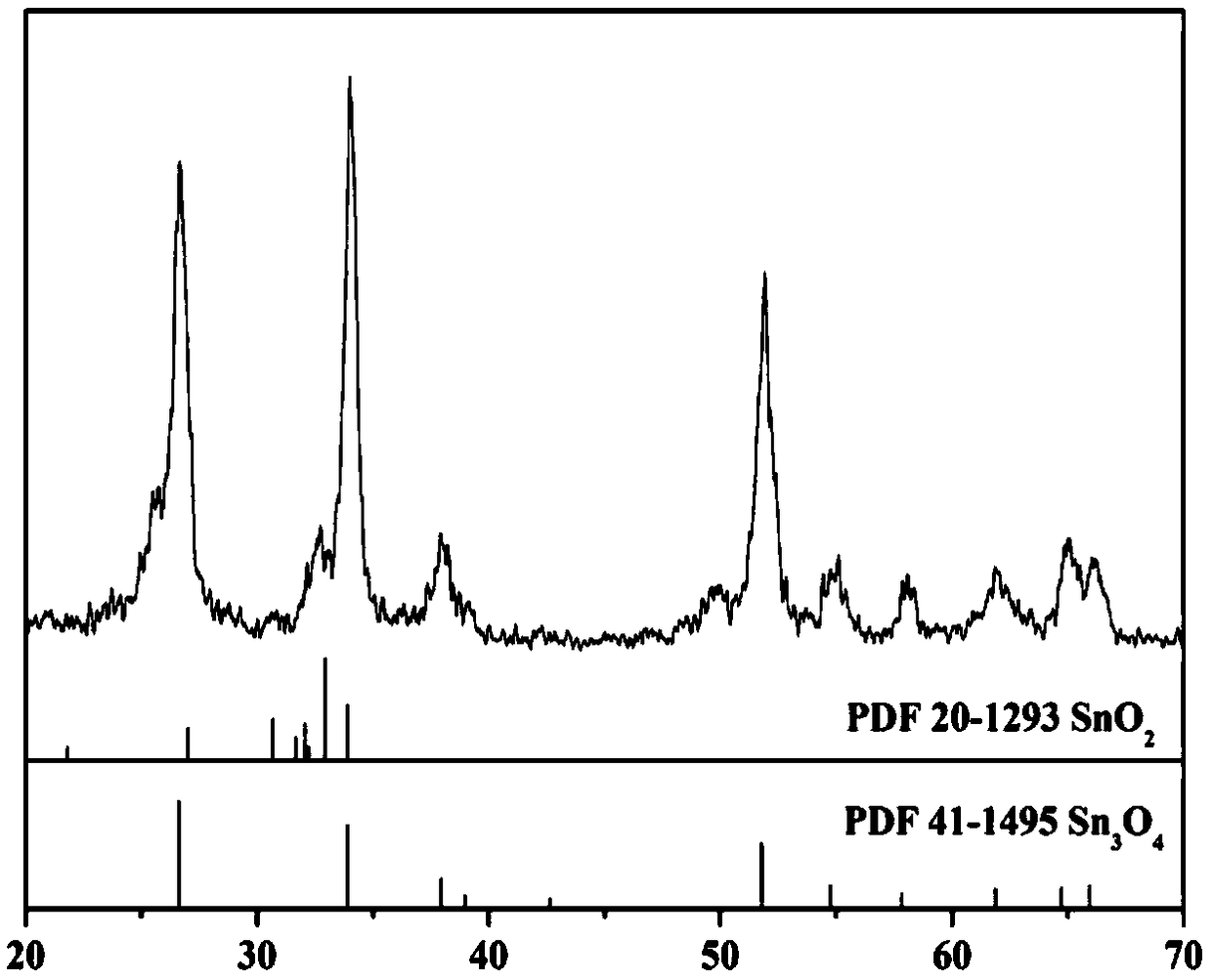

Method for preparing tin oxide/tri-tin tetra-oxide negative electrode materials with nanosheet structures for lithium ion batteries

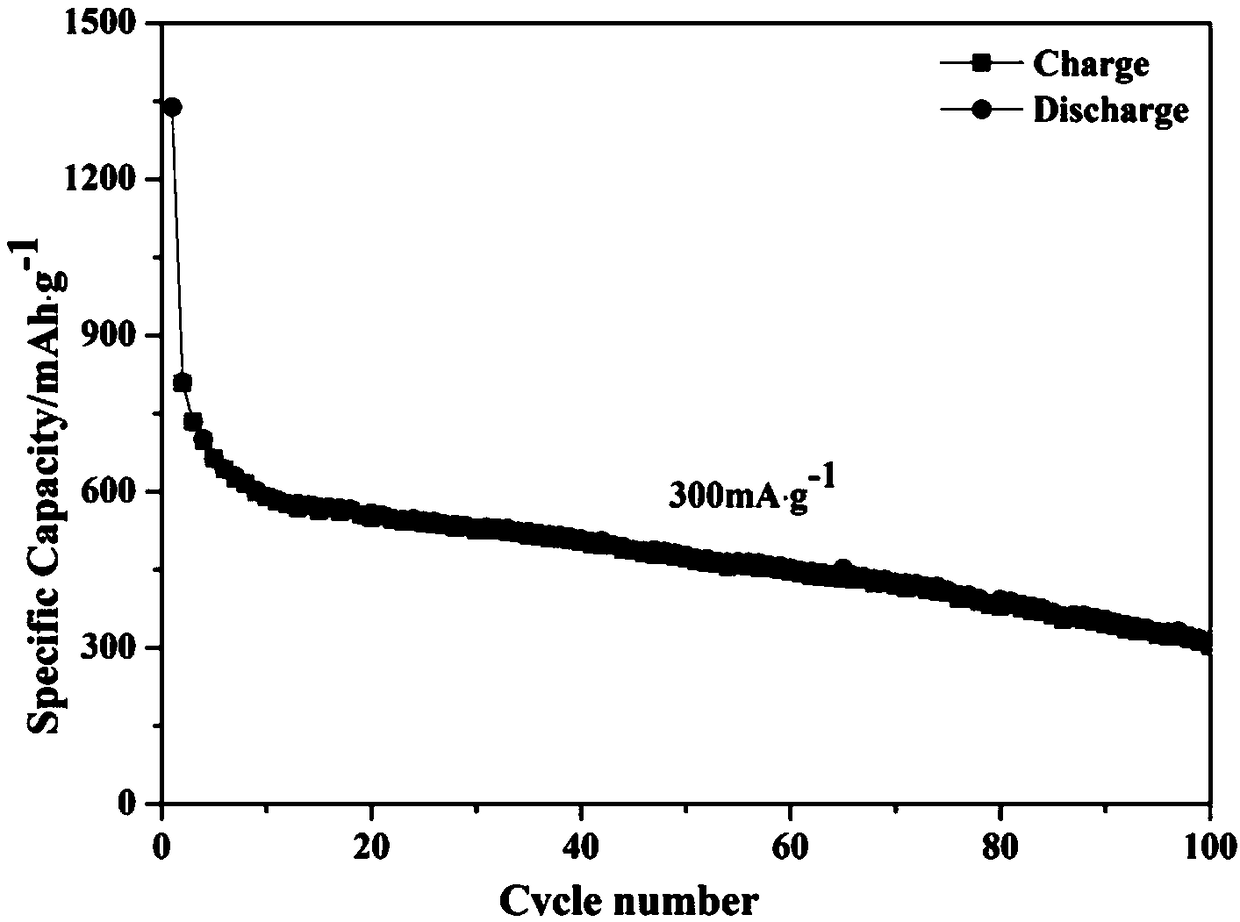

A technology for lithium tin tetroxide and ion batteries, applied in battery electrodes, nanotechnology, secondary batteries, etc., can solve the problems of less research on battery materials, and achieve improved electrochemical performance, strong crystallinity, and easy process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Put 0.5gSnCl 4 ·5H 2 O was dissolved in 40 mL of deionized water, so that it was fully dissolved to form solution A, and NaOH was dissolved in the above solution A to prepare solution B according to the element mass ratio mSn:mNa=(0.5:0.6);

[0032] 2) Under the action of magnetic stirring, 0.3 g of urea was added to the B solution, and it was continuously stirred to form a uniform mixed solution C,

[0033] 3) Put the C solution into a homogeneous hydrothermal reactor to seal, the filling ratio is controlled at 40%, put into a homogeneous hydrothermal reactor, the reaction temperature is controlled at 160°C, and the reaction time is controlled at 12h;

[0034] 4) After the reaction is over, take out the precursor, and wash it three times by centrifugation with deionized water and absolute ethanol, respectively, to obtain a white precursor and vacuum dry it at 80 °C for 12 h to obtain SnO 2 Precursor.

[0035] 5) SnO in a muffle furnace at 300°C 2 Heating for 1h,...

Embodiment 2

[0037] 1) Put 0.7012g SnCl 4 ·5H 2 O was dissolved in 50 mL of deionized water to fully dissolve it to form solution A. According to the element mass ratio m Sn :m Na =(0.7102:0.8002) Dissolve NaOH in above-mentioned solution A to prepare solution B;

[0038] 2) Under the action of magnetic stirring, 0.5g of urea was added to the B solution, and the mixture was continuously stirred to form a uniform mixed solution C,

[0039] 3) Put the C solution into a homogeneous hydrothermal reactor to seal, the filling ratio is controlled at 50%, put into a homogeneous hydrothermal reactor, the reaction temperature is controlled at 180°C, and the reaction time is controlled at 24h;

[0040] 4) After the reaction is over, take out the precursor, and wash it three times by centrifugation with deionized water and absolute ethanol, respectively, to obtain a white precursor and vacuum dry it at 80 °C for 12 h to obtain SnO 2 Precursor.

[0041] 5) SnO in a muffle furnace at 400°C 2 Heati...

Embodiment 3

[0044] 1) Put 1gSnCl 4 ·5H 2 O was dissolved in 60 mL of deionized water to make it fully dissolved to form solution A. According to the element mass ratio m Sn :m Na =(1:0.95) NaOH is dissolved in above-mentioned solution A to prepare solution B;

[0045] 2) Under the action of magnetic stirring, 0.7g of urea was added to the B solution, and it was continuously stirred to form a uniform mixed solution C,

[0046] 3) Put the C solution into a homogeneous hydrothermal reactor to seal, the filling ratio is controlled at 60%, put into a homogeneous hydrothermal reactor, the reaction temperature is controlled at 200°C, and the reaction time is controlled at 30h;

[0047] 4) After the reaction is over, take out the precursor, wash it by centrifugation with deionized water and anhydrous ethanol for 3 times, respectively, to obtain a white precursor, and vacuum dry it at 80 °C for 12 hours to obtain SnO 2 Precursor.

[0048] 5) SnO in a muffle furnace at 500°C 2 Heating for 5h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com