Monocrystal ternary positive electrode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and cathode materials, which is applied in the field of lithium-ion batteries, single crystal ternary cathode materials and their preparation, can solve the problems of low discharge specific capacity of single crystal materials, lower capacity than polycrystalline materials, and high requirements for crushing and processing. Achieve the effect of favorable capacity, excellent specific capacity, and reduced mixed discharge of lithium and nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

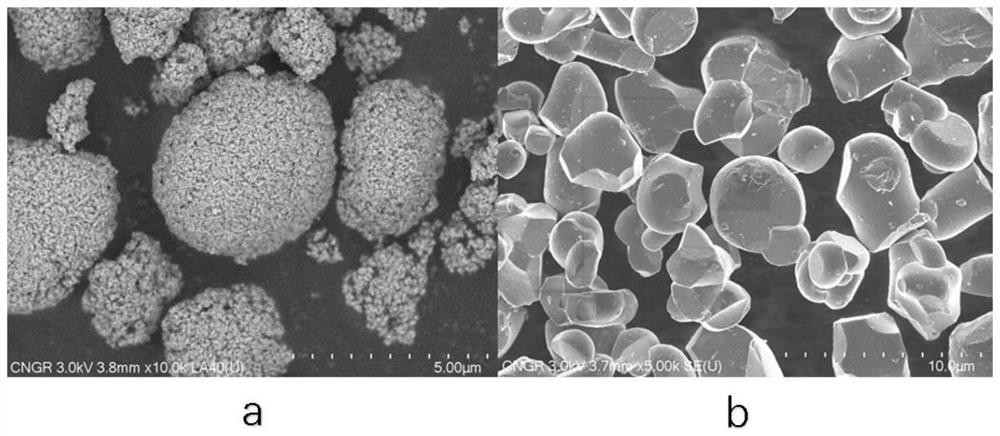

[0074] Another embodiment of the present invention provides a method for preparing a single crystal ternary positive electrode material, comprising the following steps:

[0075] Mixing the precursor of a single crystal ternary positive electrode material with a crystallinity of 60% to 70%, a lithium source and additives, and sintering in an oxygen-containing atmosphere to obtain a single crystal ternary positive electrode material with a crystallinity of 80% to 90% ;

[0076] Wherein, the single crystal ternary positive electrode material is LiNi x Co y Mn z O 2 , x+y+z=1, 0

[0077] Additives include compounds of Sr, Ca, Mg, Al, Zr, Y, Nb, W, B, the compounds include oxides, hydroxides of Sr, Ca, Mg, Al, Zr, Y, Nb, W, B And one or a combination of salts, such as SrO, SrO 2 , Sr(OH) 2 , SrCO 3 , SrCO 3 , SrNO 3 , SrCl 2 , SrSO 4 , SrS, CaCO 3 , MgCO 3 , Mg(OH) 2 , Mg(NO 3 ) 2 , ZrO, ZrCO 3 , B 2...

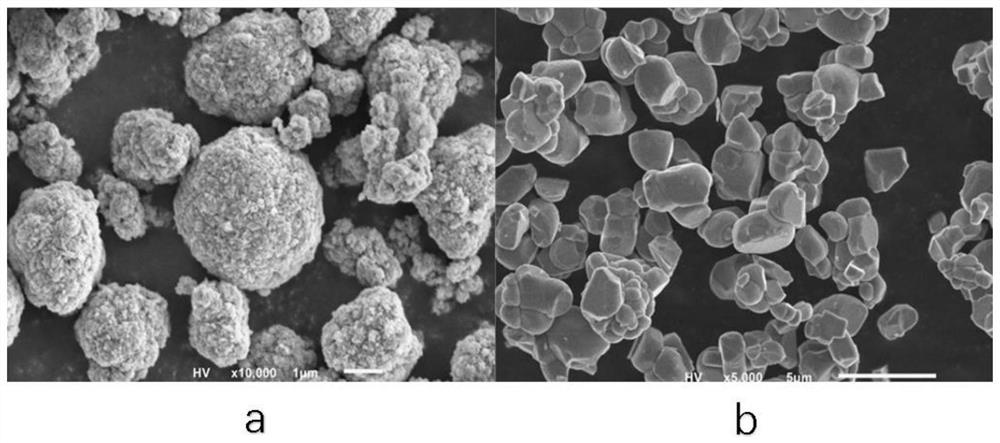

Embodiment 1

[0105] 1) The nickel, cobalt and manganese sulfate crystals with a molar ratio of 0.6:0.2:0.2 are configured into a uniform ternary metal salt mixed solution of 116g / L, and pure water and sodium hydroxide with a mass concentration of 32% are added to the reactor. The solution and 21% aqueous ammonia solution were configured as bottom liquid with pH 12.0, nitrogen protection was introduced to prevent oxidation, the stirrer was turned on, the rotating speed was 500r / min, and the temperature of the reaction kettle was raised to 60°C.

[0106] 2) the ternary metal salt mixed solution, the sodium hydroxide solution and the ammonia solution are fed into the reactor simultaneously, the flow rate of the ternary metal salt solution is 4L / h, and the flow rate of the sodium hydroxide solution is 2.0L / h, The flow rate of the aqueous ammonia solution is 0.3L / h, the reaction temperature is 60°C, the pH of the reaction system is controlled within the range of 11.9 to 12.0, a continuous proces...

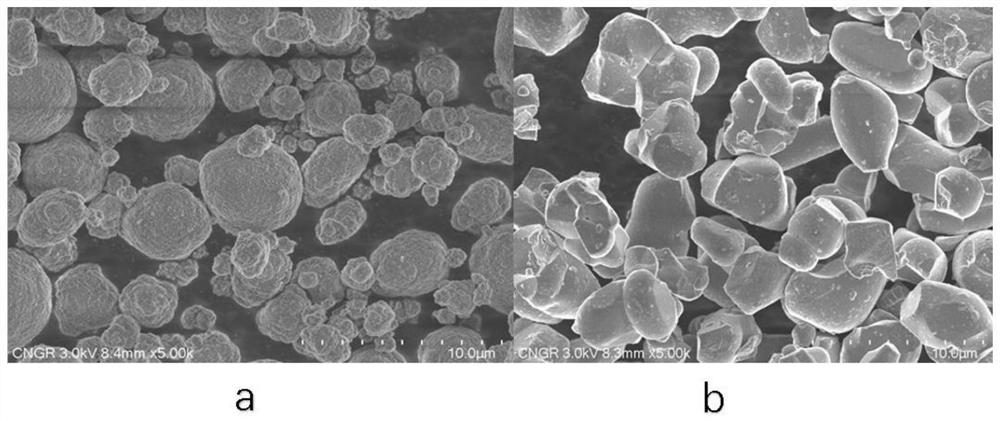

Embodiment 2

[0111] 1) The nickel, cobalt, and manganese sulfate crystals with a molar ratio of 0.7:0.1:0.2 are configured into a uniform ternary metal salt mixed solution of 116 g / L, and pure water and 32% sodium hydroxide by mass are added to the reactor. The solution and the 21% aqueous ammonia solution were configured as bottom liquid with pH of 12.0, nitrogen protection was introduced to prevent oxidation, the stirrer was turned on, the rotating speed was 600r / min, and the temperature of the reaction kettle was raised to 60°C.

[0112]2) adding the ternary metal salt mixed solution, ammonia water and liquid caustic simultaneously into the reactor, the ternary metal salt flow rate is 5L / h, the liquid caustic flow rate is 2.0L / h, the ammonia water flow rate is 0.2L / h, and the reaction temperature The temperature is controlled at 60°C, the pH range of the reaction system is controlled to be 11.9-12.0, a continuous process is adopted, feeding and discharging are continuous, and the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com