Method of separating preparation of volatile components from acorus tatarinowii

A technology for volatile components and calamus, applied in the field of medicine, can solve the problems of cumbersome steps, high cost, complicated operation, etc., and achieve the effects of reducing the loss of volatile components, avoiding long-term heating, and simple recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

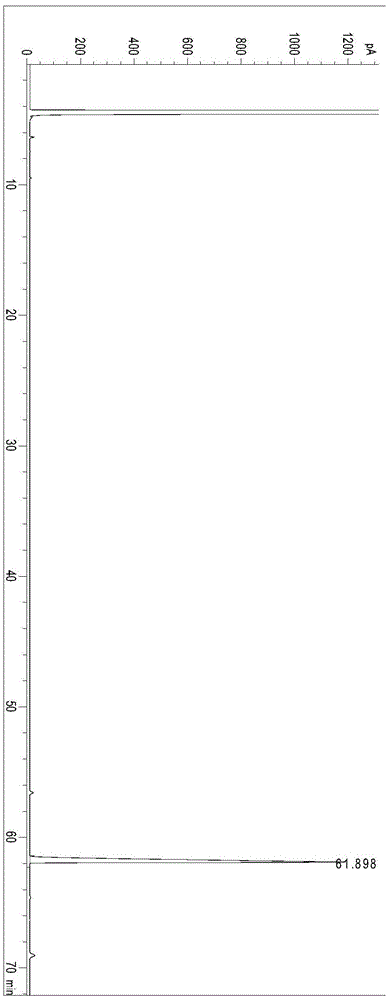

[0039] Take the coarse powder of Acorus calamus, prepare the volatile oil of Acorus calamus by steam distillation, dissolve it in n-hexane to obtain the sample solution to be separated, and inject it into the preparative SFC separation system by an autosampler. The separation conditions are as follows:

[0040] The size of the chromatographic column is Φ19×100mm, the silica gel filler, the particle size is 3-50μm; the mobile phase is CO 2 and modifying agent isopropanol, wherein, the volume ratio of the modifying agent is 10%; the flow rate is 10mL / min; the temperature is 60° C.; the pressure is 100 bar.

[0041] The ultraviolet photometric detector used for online detection, the detection wavelength is 288nm, and the peak fractions of α-asarone, β-asarone and γ-asarone were collected respectively, and the purity was analyzed by GC: α-asarone>98.3% , β-asarone>98.1%, γ-asarone>99.3%, calculated by the weight of volatile oil, the total yield of the three compounds is 77.1%. Ex...

Embodiment 2

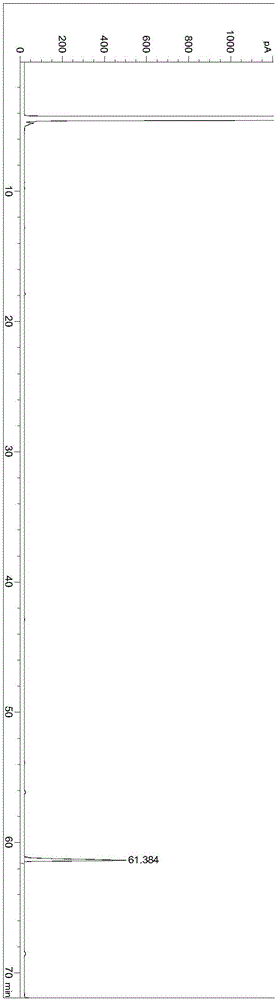

[0042] Take the coarse powder of Acorus calamus, prepare the volatile oil of Acorus calamus by steam distillation, dissolve it with n-hexane to obtain the sample solution to be separated, and inject it into the preparative SFC separation system by an autosampler, the conditions are as follows:

[0043] The size of the chromatographic column is Φ19×150mm, the silica gel filler, the particle size is 3-50μm; the mobile phase is CO 2 and modifying agent isopropanol, wherein, the volume ratio of the modifying agent is 10%; the flow rate is 30mL / min; the temperature is 50°C; the pressure is 150bar.

[0044] The ultraviolet photometric detector used for online detection, the detection wavelength is 288nm, and the peak fractions of α-asarone, β-asarone and γ-asarone were collected respectively, and the purity was analyzed by GC: α-asarone>98.5% , β-asarone>98.3%, γ-asarone>99.5%, calculated by the weight of volatile oil, the total yield of the three compounds is 74.6%. Example 3

Embodiment 3

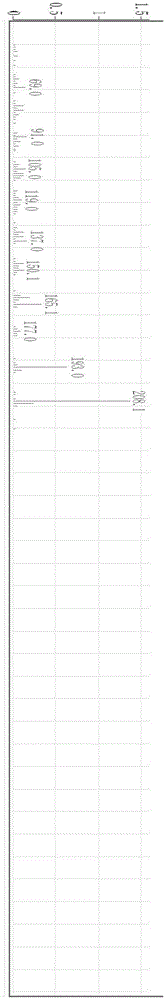

[0045] Take the coarse powder of Acorus calamus, prepare the volatile oil of Acorus calamus by steam distillation, dissolve it with n-hexane to obtain the sample solution to be separated, and inject it into the preparative SFC separation system by an autosampler, the conditions are as follows:

[0046] The size of the chromatographic column is Φ19×250mm, the silica gel filler, the particle size is 3-50μm, and the mobile phase is CO 2and modifying agent isopropanol, wherein, the volume ratio of the modifying agent is 15%; the flow rate is 20mL / min; the temperature is 40°C; the pressure is 200bar.

[0047] The ultraviolet photometric detector used for online detection, the detection wavelength is 288nm, and the peak fractions of α-asarone, β-asarone and γ-asarone were collected respectively, and the purity was analyzed by GC: α-asarone>98.70% , β-asarone>98.56%, γ-asarone>99.98%, calculated by the weight of volatile oil, the total yield of the three compounds is 79.0%. Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com