Method and device for magnesium method titanium sponge production reactor inner heat exchange

A reactor and sponge titanium technology, which is applied in the field of heat exchange inside the reactor, can solve the problems of slowing down the feeding speed, ineffective output, and difficult heat output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

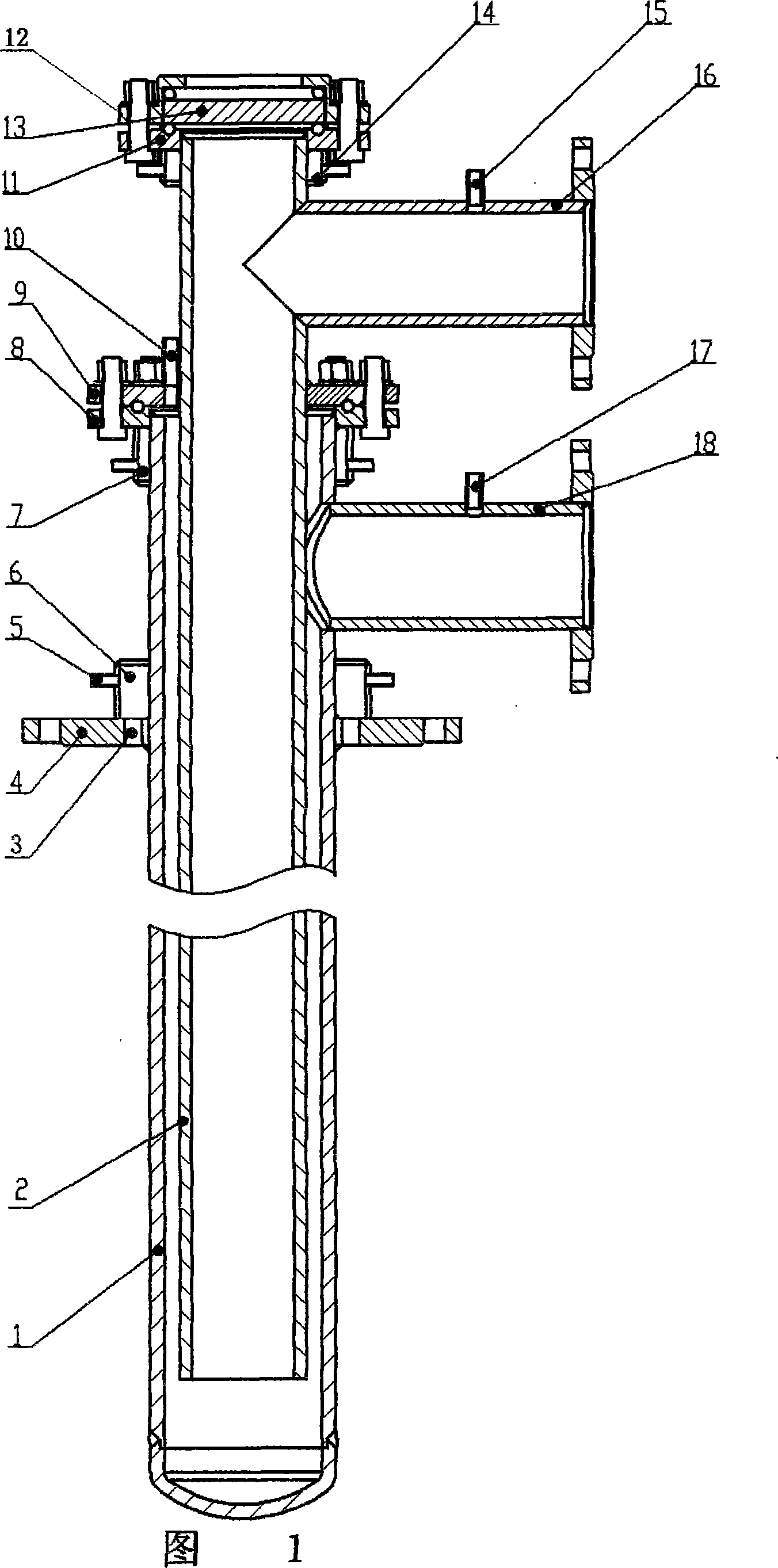

[0011] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Embodiments will be described below with reference to the drawings.

[0012] A sleeve-and-tube heat exchanger designed for implementing the internal heat exchange method of the magnesium sponge titanium production reactor, which is welded with a flange 8 on the upper end of the outer tube 1 whose lower end is a head, and on the flange 8 A cooling water jacket 7 is installed below the outer pipe 1, a return air pipe 18 is welded on the upper side of the outer pipe 1, a temperature measuring port 17 is arranged on the pipe wall of the return air pipe 18, and a flange plate 9 is welded on the upper part of the inner pipe 2. The connection between the blue plate 8 and the flange plate 9 installs the inner tube 2 in the outer tube 1, and the inner side of the flange plate 9, near the position of the inner tube 2, is provided with a nozzle 10 for measuring the temperature in the tube and inserting a thermocouple. An air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com