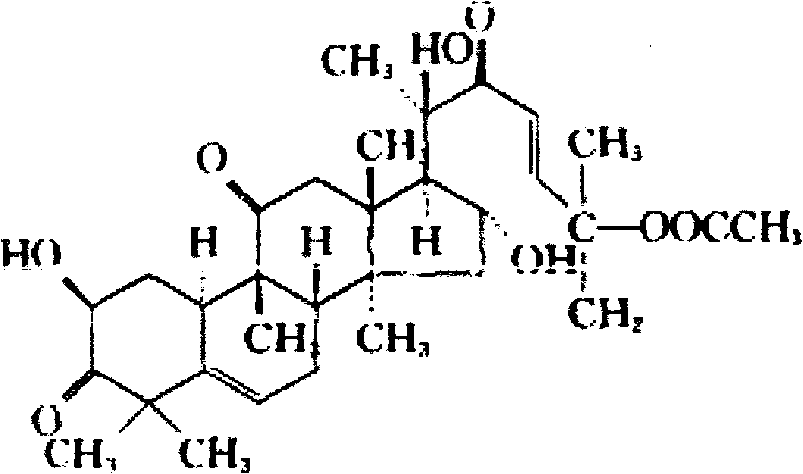

Method for extracting cucurbitacin B

A technology of cucurbitacin and activated carbon, which is applied in steroids, fermentation, organic chemistry and other directions, can solve the problems of difficulty in resin column, difficult to control hydrolysis conditions, small separation and processing capacity of silica gel column, etc., and achieves good impurity removal effect and conditions The effect of easy control and lower product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Crush melon pedicles to 20 mesh, take 1kg and mix it with ph3 hydrochloric acid aqueous solution, add 1g of β-glucosidase and mix it for enzymolysis at 40°C for 2 days, then put the raw materials of enzymolysis into the extraction container, add 15L of 80% ethanol solution for reflux extraction 2 times, each extraction for 2 hours, the combined extracts were added to a short column of activated carbon alumina (mixing ratio 5:3), the injection solution was decompressed to recover ethanol to an alcohol concentration of 30%, left to crystallize, and filtered out to obtain 260 g of crude crystals. Add chloroform to dissolve the crystals, filter to recover chloroform to 1 / 3 volume, and place the crystals to obtain 120g of secondary crystals. Dissolve the secondary crystals with 90% ethanol under reflux, then add 15g of activated carbon for injection to decolorize, filter and set aside Crystallize and dry the crystals to obtain 80g of the product cucurbitacin B, with a content...

Embodiment 2

[0026] Crush melon pedicles to 80 mesh, take 1kg and mix it with ph5 sulfuric acid aqueous solution, add 5g of amylase and mix it for enzymolysis at 30°C for 4 days, put the raw materials of enzymolysis into the extraction container, add 5L of 90% ethanol solution to reflux and extract for 3 times , extracted for 1 hour each time, the combined extracts were added to a short column of activated carbon alumina (mixing ratio 2:3), the ethanol was recovered under reduced pressure to an alcohol concentration of 40%, placed to crystallize, and 245 g of crude crystals were obtained by filtration, and the crude crystals were added to Chloroform is cold-dissolved, and the chloroform is recovered by filtration to 1 / 6 volume, and placed to crystallize to obtain 123g of secondary crystals. The secondary crystals are refluxed with 95% ethanol to dissolve, and then 20g of activated carbon for injection is added to decolorize, filtered and placed to crystallize. Dry the crystals to get the pr...

Embodiment 3

[0028] Crush melon pedicles to 60 mesh, mix 1kg with ph4 salt citric acid aqueous solution, add 5g of cellulase and mix for enzymolysis at 40°C for 3 days, put the raw materials of enzymolysis into the extraction container, add 10L of 95% ethanol solution to reflux extraction 2 times, each extraction for 2 hours, the combined extracts were added to a short column of activated carbon alumina (mixing ratio 4:3), the injection solution was decompressed to recover ethanol to an alcohol concentration of 50%, left to crystallize, and filtered to obtain 251 g of crude crystals. Add chloroform to the crystals to dissolve, filter to recover chloroform to 1 / 4 volume, and place the crystals to obtain 110g of secondary crystals, dissolve the secondary crystals with 99% ethanol under reflux, then add 15g of activated carbon for injection to decolorize, filter and set aside Crystallize and dry the crystals to obtain the product cucurbitacin B77g, with a content of 99%, (if the content is not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com