Method for extracting intravenous injection human immunoglobulin by low temperature ethanol

A technology of human immunoglobulin and low-temperature ethanol, which is applied in the field of preparation of intravenous human immunoglobulin, can solve the problems of long separation period of components, low purity, and the need to improve the yield of human immunoglobulin, so as to shorten the separation period, Effect of improving clarity and improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

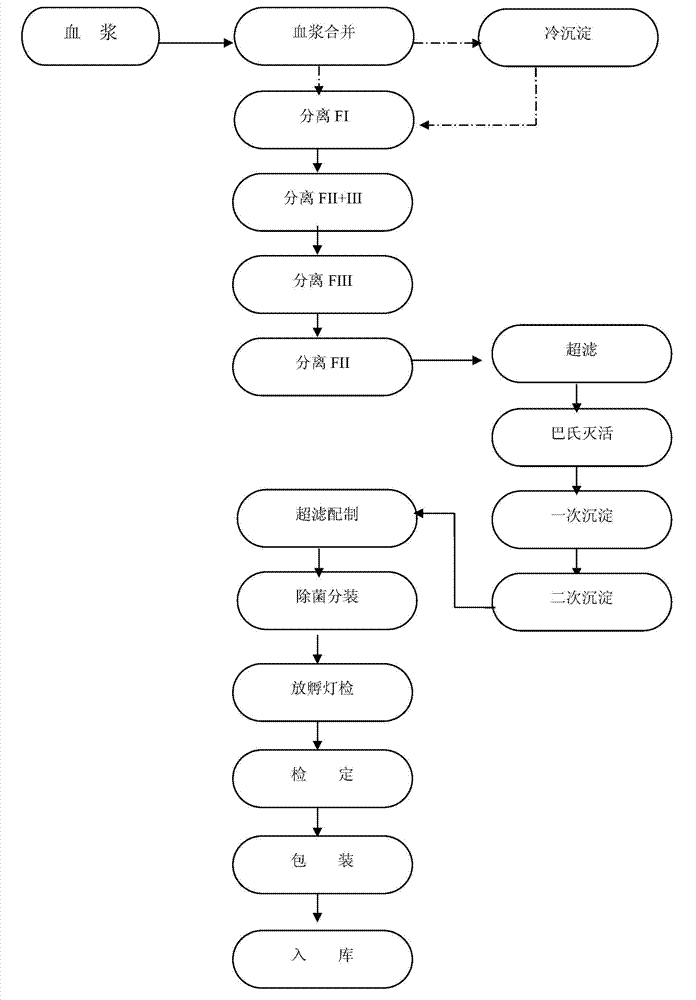

[0027] see figure 1 , the method for extracting intravenously injected human immunoglobulin with low-temperature ethanol, using human plasma as raw material, adopting low-temperature ethanol method and pressure filtration method to produce human immunoglobulin, the production operating pressure is less than 0.25MPa, comprising the following steps:

[0028] Step 1. Separation of FI from plasma:

[0029] Control the temperature of the fused human plasma at 0.0°C, adjust the protein concentration to 40g / l, adjust the conductivity of the solution to 12.0ms / cm, pH to 6.80, ethanol concentration to 7.0% by volume, and control the temperature to -1.0 °C, after the precipitation is complete, use a filter press to filter under pressure, choose a deep layer filter plate with a pore size of no more than 0.9 μm (such as 0.9 μm), control the temperature of the filter press to below -1 °C, and filter to separate The FI precipitate was obtained to obtain the FI supernatant.

[0030] Step 2...

Embodiment 2

[0045] see figure 1 , the method for extracting intravenously injected human immunoglobulin with low-temperature ethanol uses human plasma as raw material, adopts low-temperature ethanol method and pressure filtration method to produce human serum albumin, and the production operating pressure is less than 0.25MPa, comprising the following steps:

[0046] Step 1. Separation of FI from plasma:

[0047] The temperature of the fused human plasma is controlled at 2.0°C, the protein concentration is adjusted to 52.5g / l, the conductivity of the solution is adjusted to 13.1ms / cm, the pH value is adjusted to 7.05, the ethanol concentration is adjusted to 8.5% by volume, and the temperature is controlled to -2.0°C, after the precipitation is complete, use a filter press to filter under pressure, choose a deep layer filter plate with a pore size of no more than 0.9 μm (such as 0.6 μm), and control the temperature of the filter press to below -1°C. The FI precipitate was separated by fi...

Embodiment 3

[0063] see figure 1 , the method for extracting intravenously injected human immunoglobulin with low-temperature ethanol uses human plasma as raw material, adopts low-temperature ethanol method and pressure filtration method to produce human serum albumin, and the production operating pressure is less than 0.25MPa, comprising the following steps:

[0064] Step 1. Separation of FI from plasma:

[0065] Control the temperature of the fused human plasma at 4.0°C, adjust the protein concentration to 65g / l, adjust the conductivity of the solution to 14.0ms / cm, adjust the pH value to 7.30, adjust the ethanol concentration to 10.0% by volume, and control the temperature to - 3.0°C, after the precipitation is complete, use a filter press to filter under pressure, choose a deep layer filter plate with a pore size of no more than 0.9 μm (such as 0.3 μm), control the temperature of the filter press to below -1°C, and filter The FI precipitate was separated, and the FI supernatant was ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com