Separation and purification method of canine immunoglobulin and application of canine immunoglobulin

A technology for separation and purification of immunoglobulin, applied in the field of blood products, can solve problems such as difficult large-scale preparation, high demand for media, and low production efficiency, and achieve the effects of reducing separation steps, high purity, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for separating and purifying canine immunoglobulin and canine immunoglobulin products, specifically as follows:

[0051] (1) Canine plasma pretreatment: Take fresh frozen canine plasma at -20°C and slowly thaw in a refrigerator at 4°C, then centrifuge (4°C, 10000r / min, 30min), and filter the centrifuged supernatant with gauze (8 layers). Use 0.5mol / L hydrochloric acid to adjust the pH to 5.0, centrifuge again (4°C, 10000r / min, 30min), take the supernatant, and use equilibrium buffer (sodium citrate 50mmol / L, pH=5.0) to dilute to a protein concentration of 5g / L L.

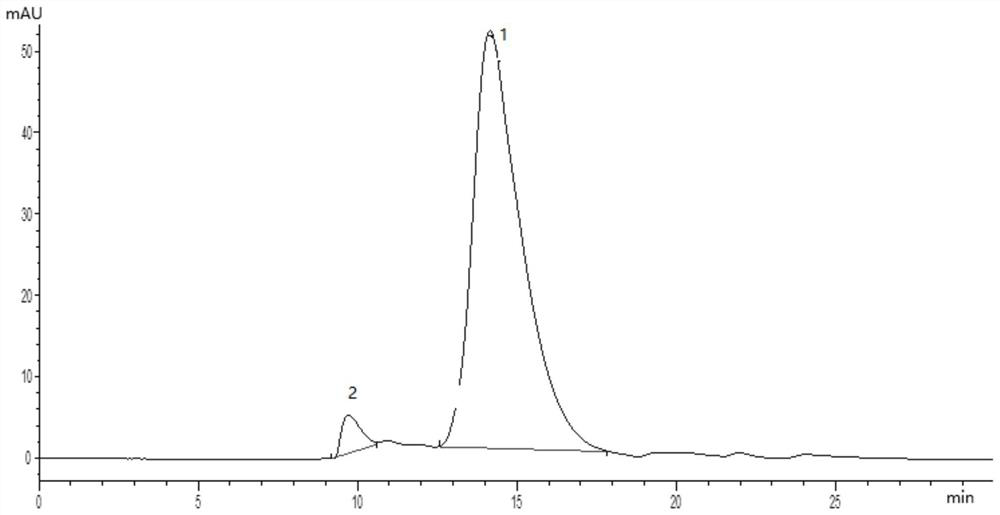

[0052] (2) Cation exchange chromatography: CM QZT 6FF medium is packed in the chromatography column, the ratio of column bed volume to sample volume is 1:5, and the packed chromatography column uses equilibrium buffer (sodium citrate 50mmol / L, pH=5.0) to balance 5 column volumes; the supernatant after centrifugal separation of canine plasma is filtered through a 0.45 μm mic...

Embodiment 2

[0058] This embodiment provides a method for separating and purifying canine immunoglobulin and canine immunoglobulin products, specifically as follows:

[0059] (1) Canine plasma pretreatment: Take fresh frozen canine plasma at -20°C and slowly thaw in a refrigerator at 4°C, then centrifuge (4°C, 10000r / min, 30min), and filter the centrifuged supernatant with gauze (8 layers). Use 0.5mol / L hydrochloric acid to adjust the pH to 6.0, centrifuge again (4°C, 10000r / min, 30min), take the supernatant, and use equilibrium buffer (sodium citrate 50mmol / L, pH=6.0) to dilute to a protein concentration of 10g / L L.

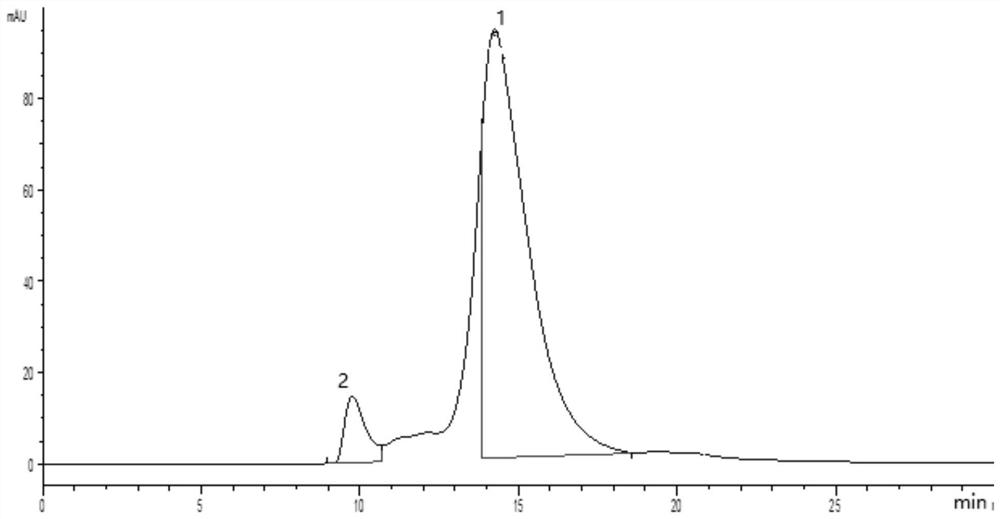

[0060] (2) Cation exchange chromatography: Pack SP QZT 6FF medium in the chromatography column, the ratio of column bed volume to sample volume is 1:5, and the packed chromatography column uses equilibration buffer (sodium citrate 20mmol / L, pH=6.0) to balance 5 column volumes; the supernatant after centrifugation of canine plasma is filtered through a 0.45 μm microfiltrati...

Embodiment 3

[0066] This embodiment provides a method for separating and purifying canine immunoglobulin and canine immunoglobulin products, specifically as follows:

[0067] (1) Canine plasma pretreatment: Take fresh frozen canine plasma at -20°C and slowly thaw in a refrigerator at 4°C, then centrifuge (4°C, 10000r / min, 30min), and filter the centrifuged supernatant with gauze (8 layers). Use 0.5mol / L hydrochloric acid to adjust the pH to 6.5, centrifuge again (4°C, 10000r / min, 30min), take the supernatant, and use equilibrium buffer (sodium citrate 20mmol / L, pH=6.5) to dilute to a protein concentration of 15g / L L.

[0068] (2) Cation exchange chromatography: Pack the Capto S medium in the chromatographic column, the ratio of the column bed volume to the loading volume is 1:15, and the packed chromatographic column uses an equilibrium buffer (sodium citrate 20mmol / L , pH=6.5) to balance 5 column volumes; the supernatant after centrifugation of canine plasma was filtered through a 0.45 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com