Clean treatment method of compound fertilizer granulation tail gas

A technology for tail gas cleaning and treatment, which is applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of high labor intensity, long solid-liquid separation cycle, and waste of resources, so as to improve the efficiency of solid-liquid separation and avoid Equipment corrosion problems, the effect of avoiding the escape of ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

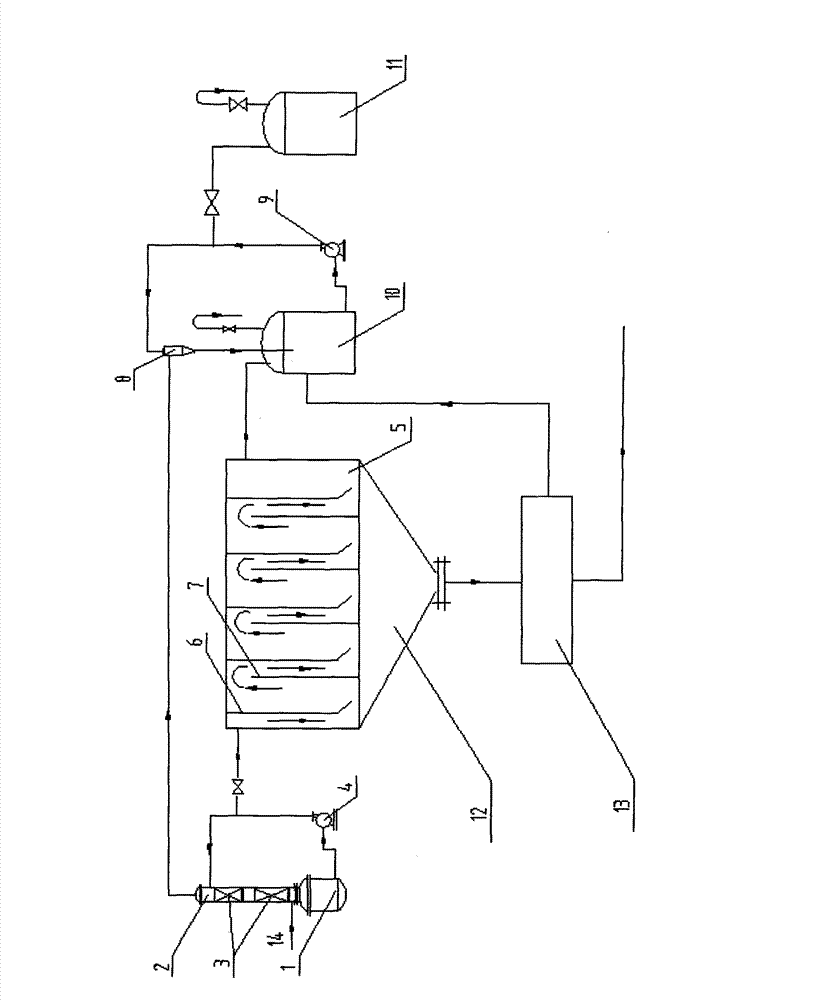

[0058] A kind of compound fertilizer granulation tail gas cleaning treatment method of the present invention

[0059] It includes a dust recovery unit and a water washing treatment unit, which is characterized in that the water washing treatment unit includes vacuum water washing, sealing baffle sedimentation, ammonia gas salt formation and fixing treatment process, and the specific treatment steps are as follows:

[0060] ①. Vacuum water absorption

[0061]Add tap water to the specified liquid level in the still 1 of the circulating absorption tower, turn on the circulation pump A4, pump the circulating water washing liquid in the still 1 of the circulating absorption tower into the top of the absorption tower 2, and the tail gas 14 after dust removal from the dust recovery unit is Under the vacuum condition generated by the jet pump 8, it flows through the tray 3 from bottom to top and makes countercurrent contact with the circulating water washing liquid, so that the fine d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com