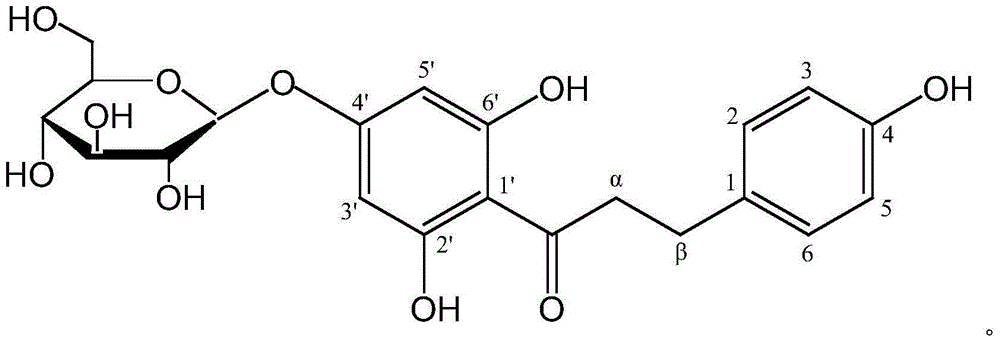

Mass isolation method of natural sweetener Trilobatin

A natural sweetener, trilobatin technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of failure to achieve large-scale preparation and separation, low separation efficiency, etc., and shorten the separation time , large amount of preparation, and simple separation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of Duosuike sweet tea extract:

[0039] Take the dried Duosuike sweet tea leaves, and the samples are pulverized by a pulverizer. Weigh 500 g of Duosuike sweet tea powder, add 20 times the weight of ethanol solution with a volume fraction of 50%, reflux for extraction for 3 hours, and filter; repeat the above steps for the filter residue, and then extract twice, combine the filtrates, and concentrate under reduced pressure to extract Shape, Duosuike sweet tea extract 45.6g.

[0040] (2) Further purification of Duosuike sweet tea extract:

[0041] After taking 20 g of the sweet tea extract obtained in step (1) and adding an appropriate amount of water to suspend it, put it into a separatory funnel, add ethyl acetate to extract 500 mL, extract 3 times, collect the ethyl acetate extract, and rotate Concentrate and dry under reduced pressure by evaporation to obtain 8.3 g of ethyl acetate extract.

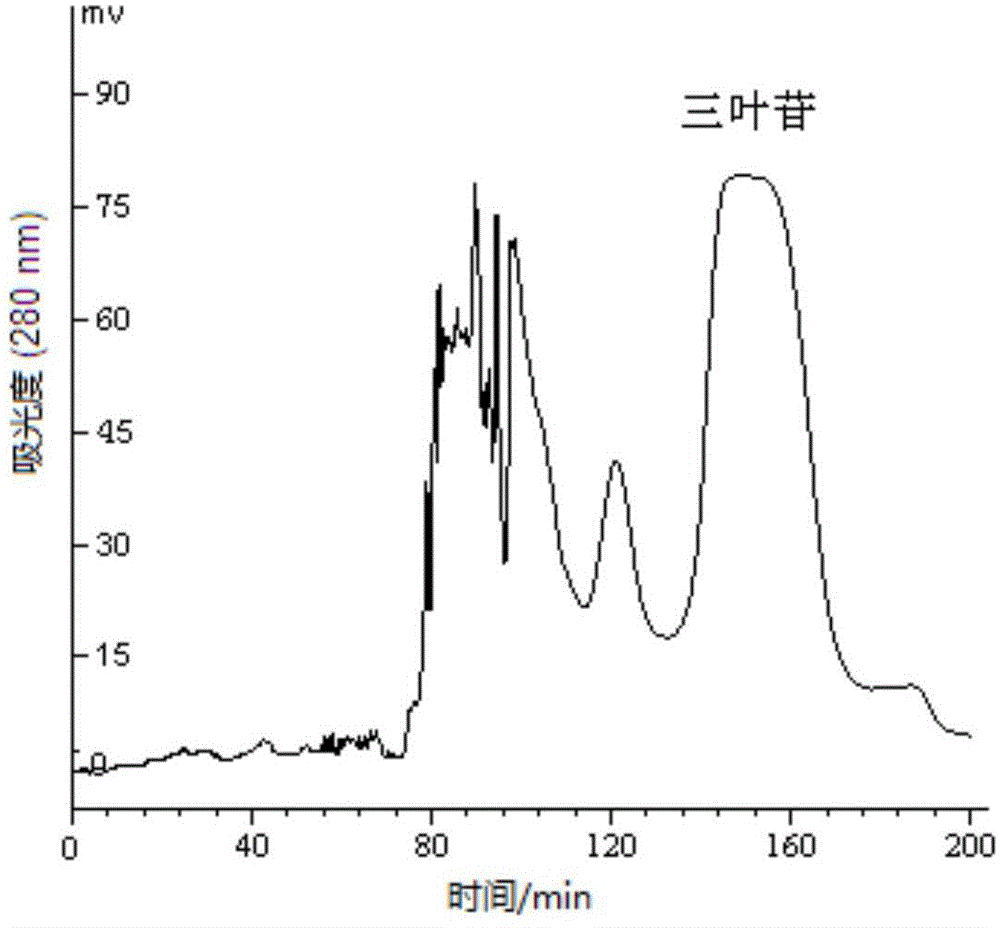

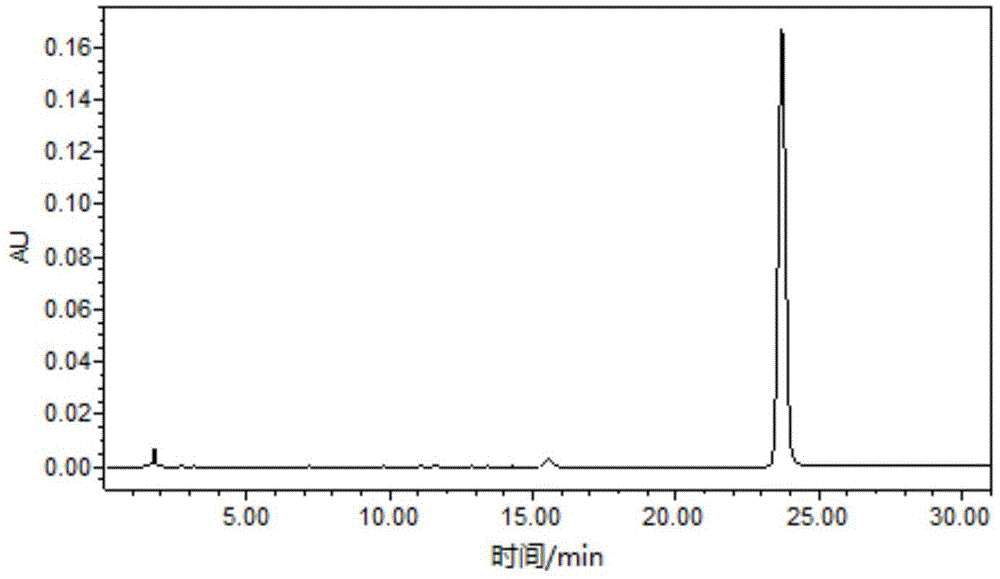

[0042] (3) trilobatin in the crude ethyl acetate isolate...

Embodiment 2

[0050] (1) Preparation of Duosuike sweet tea extract:

[0051] Take 200 g of Duosuike sweet tea powder pulverized by a pulverizer, add 50 times the weight of the ethanol solution with a volume fraction of 70%, reflux for extraction for 2.5 hours, and filter; repeat the above steps for the filter residue, and then extract twice, combine the filtrate, and depressurize Concentrate to the extract form, Duosuike sweet tea extract 21.4g.

[0052] (2) Further purification of Duosuike sweet tea extract:

[0053] After taking 10 g of the sweet tea extract obtained in step (1) and adding an appropriate amount of water to suspend it, put it into a separatory funnel, add ethyl acetate to extract 400 mL at the same time, extract 3 times, collect the ethyl acetate extract, and rotate Evaporate and concentrate to dry under reduced pressure to obtain 4.2 g of ethyl acetate extract.

[0054] (3) high-speed countercurrent chromatographic separation of trilobatin in the ethyl acetate extract:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com