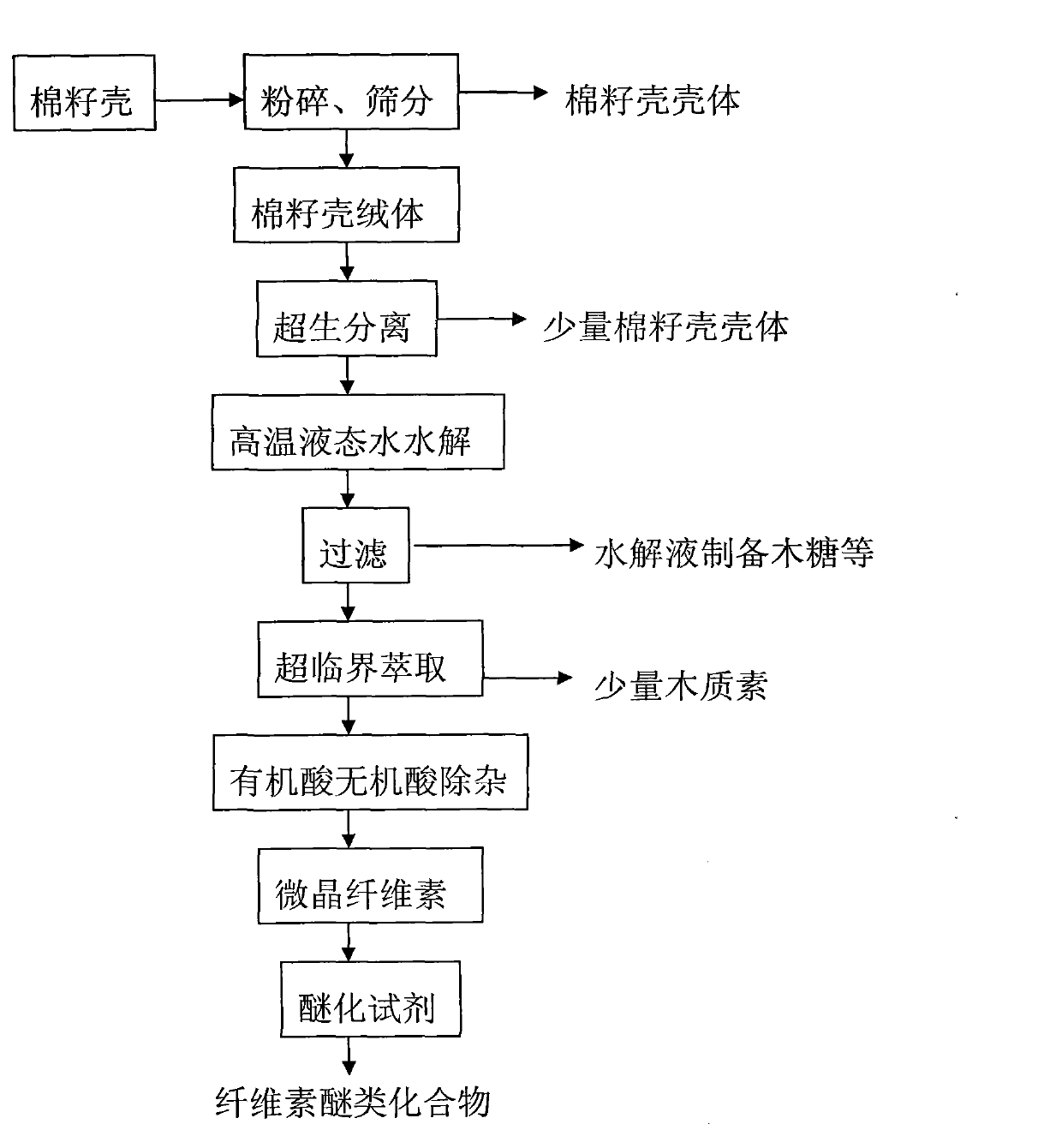

Method for preparing cellulose compounds by using cottonseed hull as raw material

A cellulose and cottonseed husk technology, applied in the cotton industry, chemical industry, and agricultural fields, can solve the problems of low added value of products, insignificant economic benefits, etc., and achieve obvious economic and social benefits, low discharge of three wastes, and treatment capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get 200 grams of local cottonseed hulls in Alar City, Xinjiang, pulverize with a pulverizer equipped with a 40-mesh sieve, and the pulverized matter is sieved with a 40-mesh and 60-mesh sieve, and utilizes the suede (cellulose 71.7% and semi-fiber 10.2% lignin, 18.1% lignin). Put the fleece into a beaker, add water and put it into an ultrasonic detergent to vibrate at a frequency of 20KHz for 15 minutes, the shell wrapped in the fleece sinks to the bottom of the beaker, and the upper layer suspension is sent into a high-pressure reactor and heated up , hydrolyzed at 140°C for 3 hours, the hydrolyzed solution was ultrasonically settled, the suspension was filtered and washed to obtain solid wool; the wool was added with supercritical CO 2 In the extractor, add 10% ethylene glycol extraction aid, filter and separate to obtain a small amount of lignin and suede (crude cellulose); add 1:0.5:1 nitric acid, formic acid and acetic acid solution to the suede (crude cellulose), ...

Embodiment 2

[0026] Get 200 grams of local cottonseed hulls in Alar City, Xinjiang, pulverize with a pulverizer equipped with a 40-mesh sieve, and the pulverized matter is sieved with a 40-mesh, 60-mesh, and 80-mesh sieve, and the cashmere body (cellulose 68.1% , hemicellulose 10.3%, lignin 21.6%). Put the fleece into a beaker, add water and put it into an ultrasonic detergent for vibration, frequency 25KHz, vibration for 25 minutes, the upper suspension is sent to a high-pressure reactor, heated, hydrolyzed at 160°C for 3 hours, and the hydrolyzed solution is ultrasonically settled , the suspension was filtered and washed to obtain solid fluff; the fluff was added with supercritical CO 2 In the extractor, add 10% 1,4-butanediol extraction aid, filter and separate to obtain a small amount of lignin and suede (crude cellulose); add 1:1 nitric acid and acetic acid solution to the suede (crude cellulose), Heating and reacting for 1.5 hours, filtering to obtain white cellulose, and crushing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com