Washing machine used for summer squashes

A technology of zucchini and washing machine, which is applied in the field of agricultural product processing, can solve the problems of melon flesh not being discharged in time, affecting the cleaning effect, restricting the cleaning efficiency, etc., and achieving the effects of saving manpower, improving the cleaning effect and improving the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

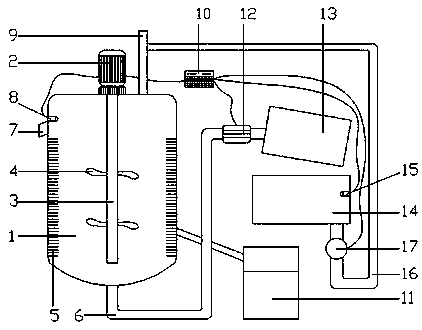

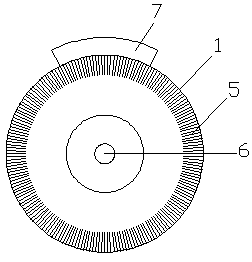

[0023] Such as figure 1 , 2 Shown, a kind of cleaning machine for zucchini comprises stirring tank 1, PLC controller 10 and the ozone generator 11 that links to each other with stirring tank 1; Arc surface structure, and the bottom is connected with the mixing pipe 6; the output end of the stirring motor 2 is connected with the stirring shaft 3, and the stirring shaft 3 is connected with the stirring blade 4; the inner wall of the stirring tank 1 is provided with a brush 5 along the circumference, near the upper end An overflow tank 7 is connected to the wall of the tank, and the upper end of the overflow tank 7 is provided with a first liquid level sensor 8 corresponding to the interior of the mixing tank 1; the end of the mixing pipe 6 is connected with a mixing pump 12, and the mixing pump 12 The feed port is connected with a drainage tank 13; a water collection tank 14 is arranged directly below the drainage tank 13, and a second liquid level sensor 15 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com