Method for preparing cannabidiol

A cannabidiol and chromatography technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of time-consuming and labor-intensive processing, large consumption of organic solvents, unsatisfactory comprehensive yield, etc. The effect of large sample volume and short separation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

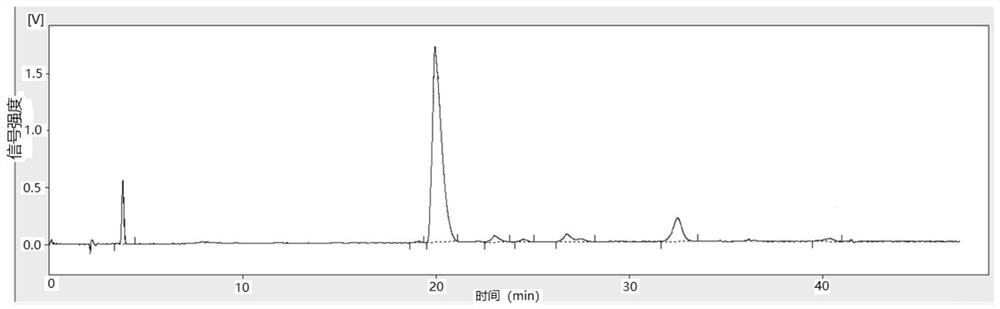

Image

Examples

Embodiment 1

[0049] In this embodiment, cannabis flowers and leaves are prepared by supercritical fluid chromatography to prepare cannabidiol, and the operation method is as follows:

[0050] Weigh 50g of dried cannabis flower leaves, extract twice with 500mL n-hexane at 25°C, combine the extracts, concentrate to an anhydrous thick paste (weight 4.17g, converted cannabidiol is 0.92g), and use n-heptane Dissolve at 30°C, pass through a short column of silica gel packed with 1.1 g of silica gel, rinse with 5 mL of n-heptane, combine, inject into a supercritical fluid chromatography injection valve, and perform continuous gradient separation. Equipment parameters are: equipment model: CS-SFC50, chromatographic column: high-purity silica gel (Hedera Si) 9μm 15×250mm, column temperature: 30°C, back pressure: 12MPA, detection wavelength: 220nm. The mobile phase elution procedure is:

[0051] time (min) Flow rate (mL / min) A: CO 2

B: Dichloromethane C: Methanol 0 2 95%...

Embodiment 2

[0062] In this embodiment, cannabis flowers and leaves are prepared by supercritical fluid chromatography. The difference between the operation method and Example 1 is only the mobile phase elution procedure, which is:

[0063] time (min) Flow rate (mL / min) A: CO 2

B: Dichloromethane 0 2 95% 5% 5 2 65% 30% 52 2 45% 55% 60 2 95% 5%

[0064] Collect the target peak product at 18.5-21.4min, and recover the solvent; collect 0-4min, recover the solvent and then destroy it; collect the other peaks and recover the solvent to make an oily thick paste for later use.

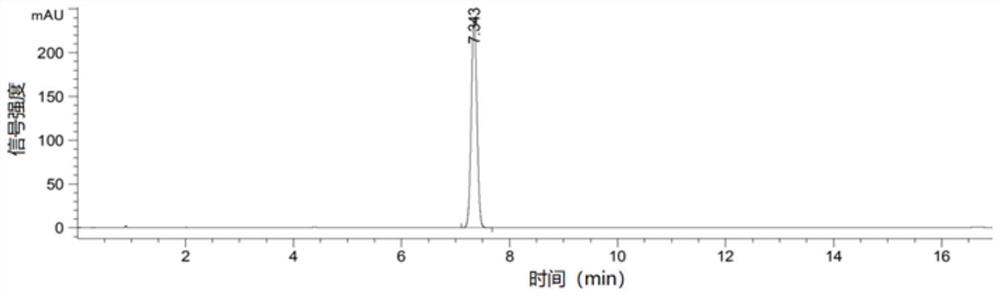

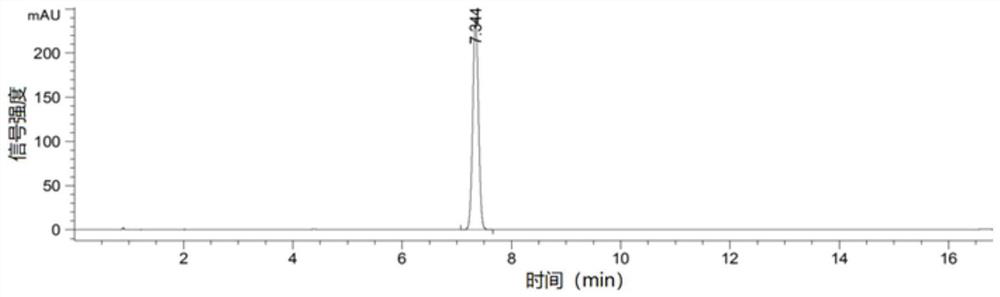

[0065] The target peak product is concentrated under reduced pressure and vacuum dried, and crushed to a size below 100 mesh to obtain the high-purity cannabidiol product. Use high performance liquid chromatography to carry out the detection of its purity, and specific content is consistent with embodiment 1, and its liquid chromatogram is as follows Figure 4 As shown,...

Embodiment 3

[0068] In this example, a large amount of cannabis flowers and leaves are prepared by supercritical fluid chromatography to prepare cannabidiol, and the operation method is as follows:

[0069] Weigh 5Kg of dried cannabis flower leaves, extract twice with 50L 95% ethanol at 25°C, combine the extracts, concentrate to an anhydrous thick paste (weight 514g, converted cannabidiol is 93.22g), and use n-heptane : Ethyl acetate (V / V=8:1) was dissolved at 30°C, passed through a short column of silica gel packed with 260g of silica gel, rinsed with 100mL of n-heptane, merged, injected into the supercritical fluid chromatography injection valve, and carried out continuous Isocratic elution. The equipment parameters are: equipment model: CS-SFC100, chromatographic column: phenylene ether group bonded silica gel 25 μm 80×400 mm, column temperature: 40°C, back pressure: 15MPA, detection wavelength: 220nm. The mobile phase elution procedure is:

[0070] time (min) Flow rate (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com