Nano-TiO2 loaded chitosan compound and preparation method thereof

A technology of nano-titanium dioxide and chitosan, which is applied in textiles, papermaking, and fiber treatment, can solve the problems of poor antibacterial durability, low safety, and delayed antibacterial effect, and achieve mild reaction conditions, wide application range, and good sustained release performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

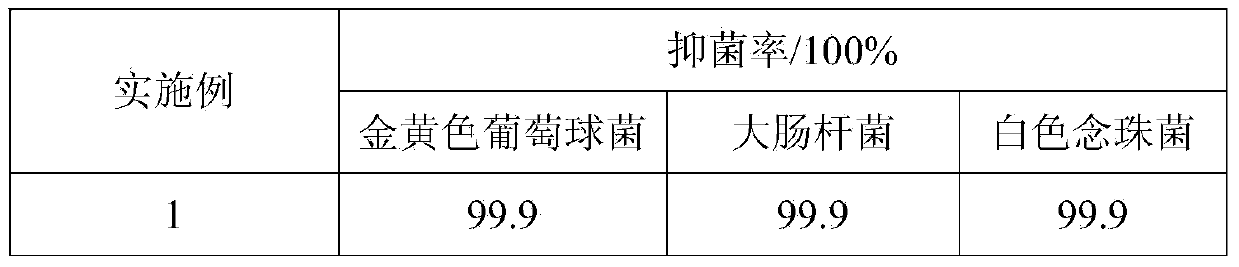

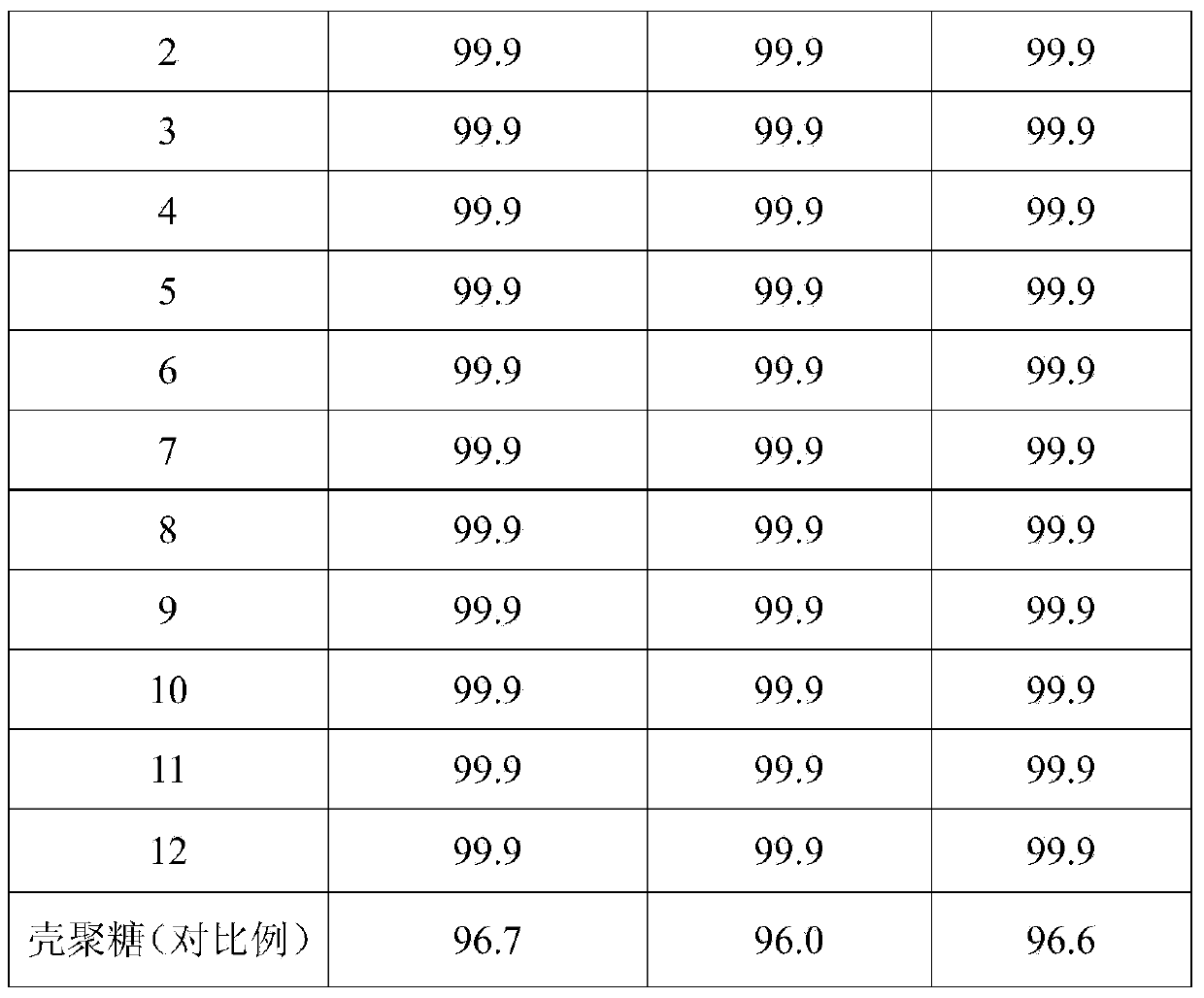

Examples

Embodiment 1

[0023] Example 1: Use acetic acid solution to fully dissolve chitosan, prepare a chitosan solution with a mass percentage of 0.5%, take 15mL of the above chitosan solution and 0.0365g of nano-TiO 2 Placed in a beaker, ultrasound makes nano-TiO 2 Disperse uniformly in the chitosan solution, and then add 0.15mL Tween80 to obtain the pre-emulsified water phase mixture; add 100mL petroleum ether, 50mL liquid paraffin and 7.5mL emulsifier Span80 to a three-necked flask, and after stirring, it becomes oil Phase mixture. Add the pre-emulsified water phase mixture to the oil phase mixture uniformly and slowly by spraying, control the reaction temperature at 30°C, stir for 0.5h, add 0.1mL glutaraldehyde, continue to stir for 4h, stand still, filter with suction, and wash. After drying, chitosan loaded nano-TiO is obtained 2 Antibacterial microspheres, the electron microscope photos are as figure 1 As shown, figure 1 The scale bar in is 200μm.

Embodiment 2

[0025] Use acetic acid solution to fully dissolve chitosan, prepare a chitosan solution with a mass percentage of 2%, take 15mL of the above chitosan solution and 0.0365g of nano-TiO 2 Placed in a beaker, ultrasound makes nano-TiO 2 Disperse uniformly in the chitosan solution, then add 0.15mL Tween80 to obtain the pre-emulsified water phase mixture; add 100mL petroleum ether, 50mL liquid paraffin and 7.5mL emulsifier Span80 to a three-necked flask, and stir it evenly by mechanical means, which is an oil Phase mixture. Add the pre-emulsified water phase mixture to the oil phase mixture uniformly and slowly by spraying, control the reaction temperature at 30°C, stir for 0.5h, add 0.39mL glutaraldehyde, continue to stir for 4h, stand still, filter and wash, After drying, chitosan loaded nano-TiO is obtained 2 Antibacterial microspheres.

Embodiment 3

[0027] Use acetic acid solution to fully dissolve chitosan, prepare a chitosan solution with a mass percentage of 1%, take 15mL of the above chitosan solution and 0.0365g of nano-TiO 2 Placed in a beaker, ultrasound makes nano-TiO 2 Disperse uniformly in the chitosan solution, and then add 0.075mL Tween80 to obtain a pre-emulsified water phase mixture; add 100mL petroleum ether, 50mL liquid paraffin and 7.5mL emulsifier Span80 to a three-necked flask, and stir it evenly, and it is an oil Phase mixture. Add the pre-emulsified water phase mixture to the oil phase mixture uniformly and slowly by spraying, control the reaction temperature at 30°C, stir for 0.5h, add 0.2mL glutaraldehyde, continue stirring for 4h, stand still, filter and wash, After drying, chitosan loaded nano-TiO is obtained 2 Antibacterial microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com