Photovoltaic electric cable for switching between the wind power and solar power

A solar energy conversion, photovoltaic cable technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of narrow temperature resistance range, difficult to adapt, insufficient adaptability, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

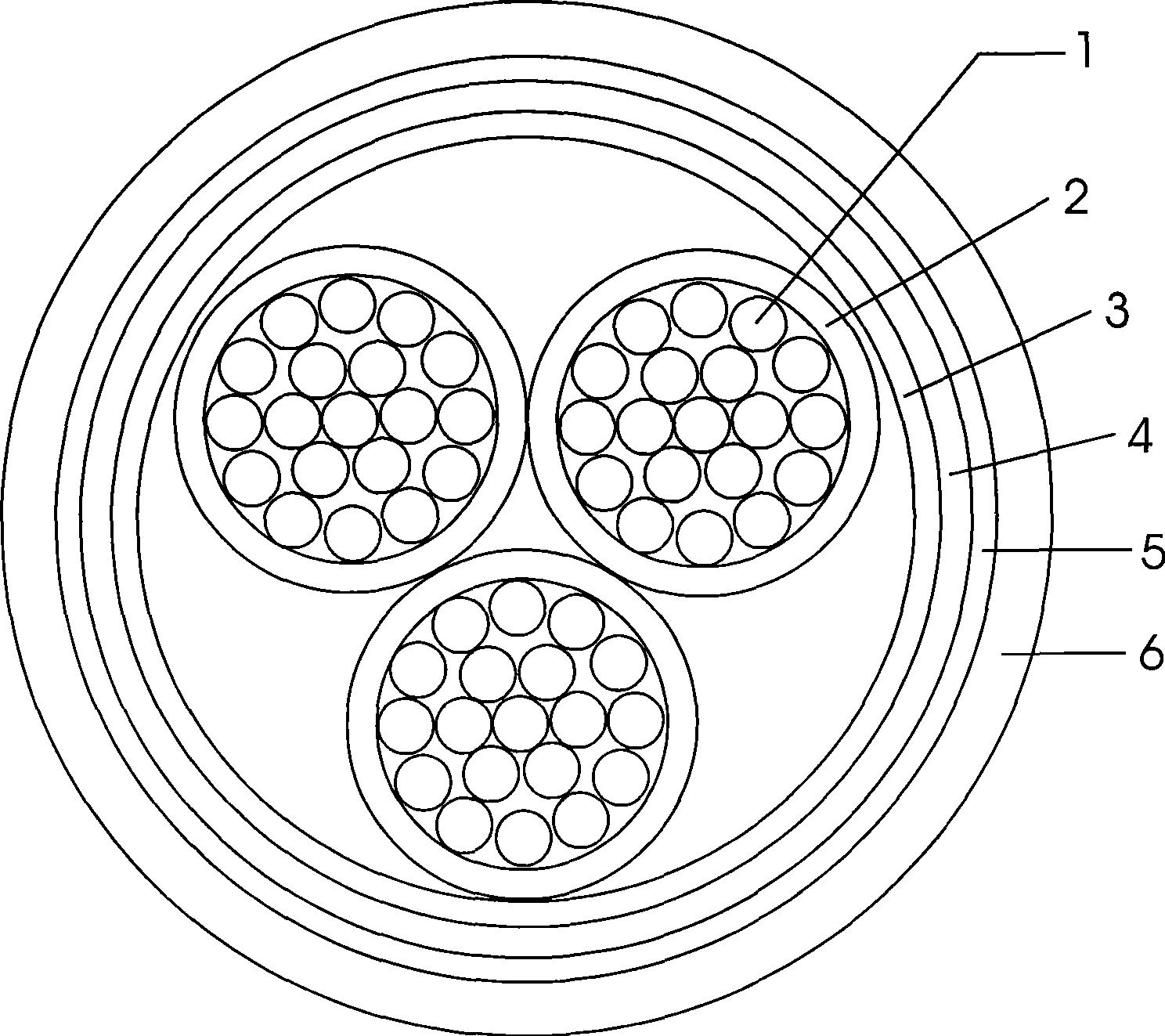

[0028] Such as figure 1 As shown, a photovoltaic cable for wind energy and solar energy conversion of the present invention includes an insulated wire core, and the insulated wire core is a copper conductor 1 coated with an irradiation cross-linked low-smoke and halogen-free insulating layer 2, and the insulated wire core The outer layer is concentrically wrapped with glass fiber tape 3 , metal shielding layer 4 , water blocking tape 5 and radiation cross-linked low-smoke halogen-free sheath 6 . Among them, the copper conductor 1 is an annealed copper conductor with a circular cross section. The annealed copper conductor is composed of a plurality of tinned copper strands twisted, and the insulated wire core is made of a plurality of cores required by the production specification. Copper conductor bundles with low-smoke and halogen-free insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com