Grinding treatment method for thinned liquid crystal glass substrate

A technology of liquid crystal glass substrate and processing method, which is applied in chemical instruments and methods, grinding devices, grinding machine tools, etc., can solve the problems of liquid crystal substrate yield not meeting customer needs, untreated concave and convex points of incoming materials, affecting production efficiency, etc. , to reduce the reverse throw rate after grinding, shorten the polishing time, and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

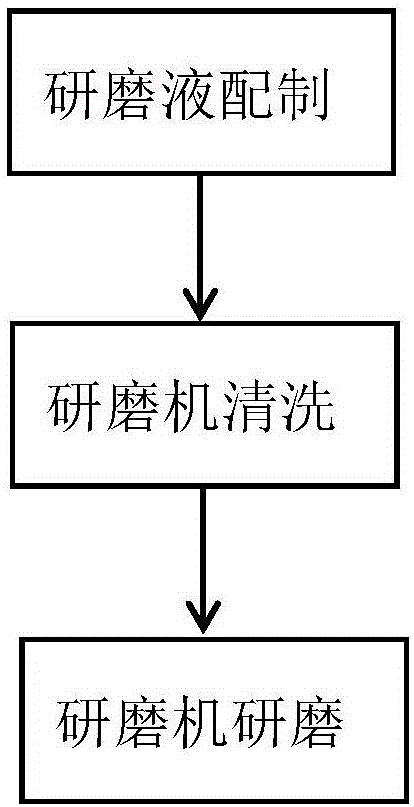

[0027] A method for grinding a liquid crystal glass substrate after thinning, comprising the following steps:

[0028] (1) Preparation of grinding liquid: grinding liquid is formed by mixing ultrapure water and cerium oxide polishing powder;

[0029] Connect the ultrapure water pipeline from the power department to the grinding machine;

[0030] Clean the grinding barrel first to ensure that there is no foreign matter or lumpy polishing powder on the inner wall; then add 2 / 3 bucket of ultra-pure water, start the circulation of the grinding liquid, wash away the remaining grinding liquid in the pipeline, and then wash the remaining grinding liquid in the grinding barrel Pour out the pure water. If there are foreign objects in the grinding barrel, continue to wash until it is clean;

[0031] Add ultrapure water to about 5cm above the grinding bucket, start stirring, and add 2000mL particle size of 1.0 μm cerium oxide polishing powder; the model of cerium oxide polishing powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com