Metallographic preparation method of tungsten-zirconium alloy

A technology of alloy and tungsten-zirconium, which is applied in the field of metallographic preparation of tungsten-zirconium alloy, can solve the problems of fuzzy display of microstructure during polishing, extremely high requirements for parameter control, and extremely high requirements for operators, so as to achieve real and clear structure morphology , Promote production efficiency, improve accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of the dichromium trioxide polishing agent used in embodiment 1 and embodiment 2 comprises the following steps:

[0031] Mixed solution preparation: add chromium trioxide to water to form a mixed solution;

[0032] Primary filtration: pour the mixture into 200-mesh single-layer copper mesh for filtration, and keep the filtered suspension;

[0033] Secondary filtration: Pour the first-filtered suspension into a 200-mesh double-layer copper mesh and filter again; let the second-filtered suspension stand for 40 minutes, and remove the viscous part of the lower layer as a chromium oxide polishing agent. The ratio of chromium trioxide added in the mixed solution: water is 3g: 100mL.

[0034] Example 1

[0035] Prepare metallographic sample according to the method of the present invention, comprise the following steps:

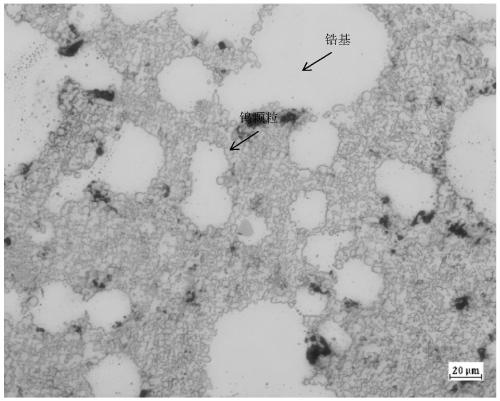

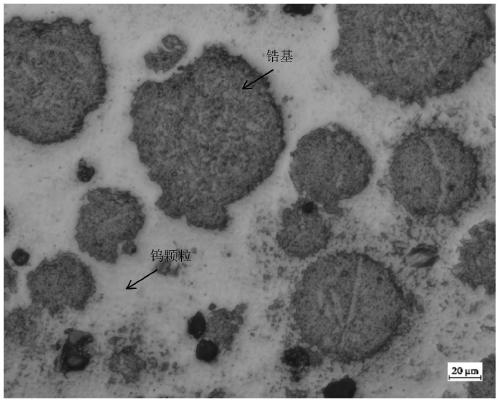

[0036] 1) Sampling; select tungsten-zirconium alloy prepared by sintering method (tungsten content 55wt%), intercept about 2cm 2 sample, ...

Embodiment 2

[0045] Prepare metallographic sample according to the method of the present invention, comprise the following steps:

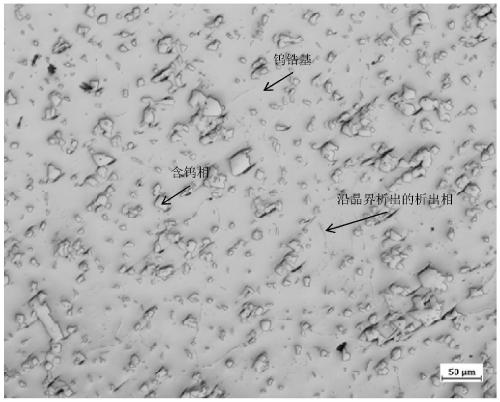

[0046] 1) Sampling: tungsten-zirconium alloy (60% tungsten content) was prepared by smelting in a vacuum furnace, and about 2cm was taken. 2 sample, the cut surface is the inspection surface;

[0047] 2) Grinding; use sandpaper to grind the inspection surface to remove surface scratches; the grinding time is 4 minutes. After the grinding is completed, put the sample in alcohol for ultrasonic cleaning for 40 seconds, take it out and dry it; specifically include the following steps:

[0048] Coarse grinding: rough grinding with 180 mesh water sandpaper;

[0049] Fine grinding: Rotate the sample 90 degrees, use 240 mesh, 400 mesh, 600 mesh, 800 mesh silicon carbide water sandpaper to grind in turn, use water as lubricant, and rotate the sample 90 degrees in the same direction after grinding Then carry out the next pass of grinding;

[0050] Fine grinding: Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com