Alkaline non-polluting aluminum alloy electrochemical polishing solution

A polishing liquid and aluminum alloy technology, which is applied in the field of electrochemical polishing, can solve the problems of high price, high cost, and poor production conditions, and achieve the effects of less aluminum loss, short polishing time, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1T

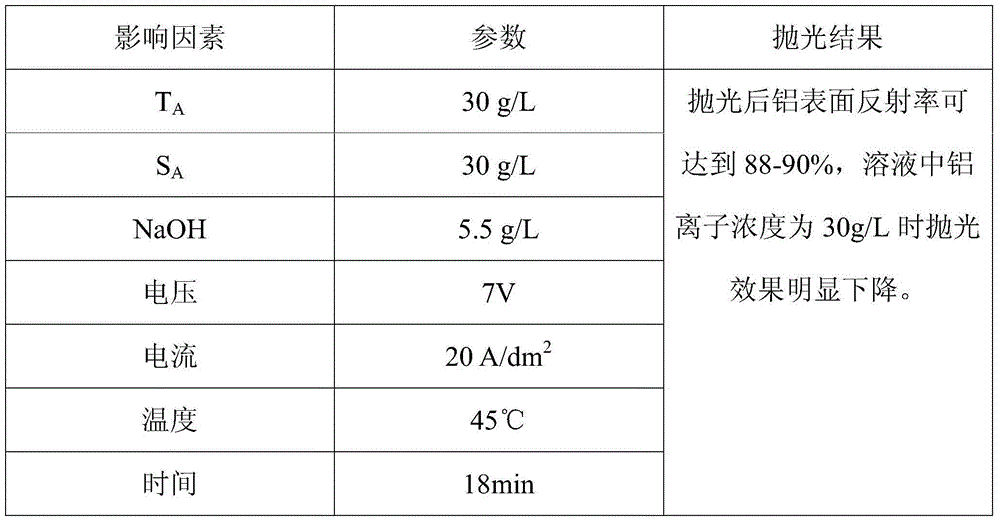

[0022] Example 1 with T A Be the performance detection of the polishing liquid of the present invention of brightener

[0023] Cut the industrial pure aluminum with a purity of 99.2% into pieces, after mechanical polishing, metallographic sandpaper grinding and chemical degreasing, use the polishing solution shown in Table 1 and the process conditions shown in Table 1, with stainless steel as the auxiliary electrode , The potentiostat controls the voltage, the electric mixer controls the flow rate of the solution, and the constant temperature bath controls the operating temperature for polishing, followed by washing, drying and testing the quality.

[0024] According to production needs, comprehensively evaluate the polishing effect from various aspects:

[0025] (1) The light reflectance of the silver mirror is 100% as a reference, and the light reflectance of the polished aluminum surface is measured by a photocell to indicate the degree of polishing leveling. The high...

Embodiment 2T

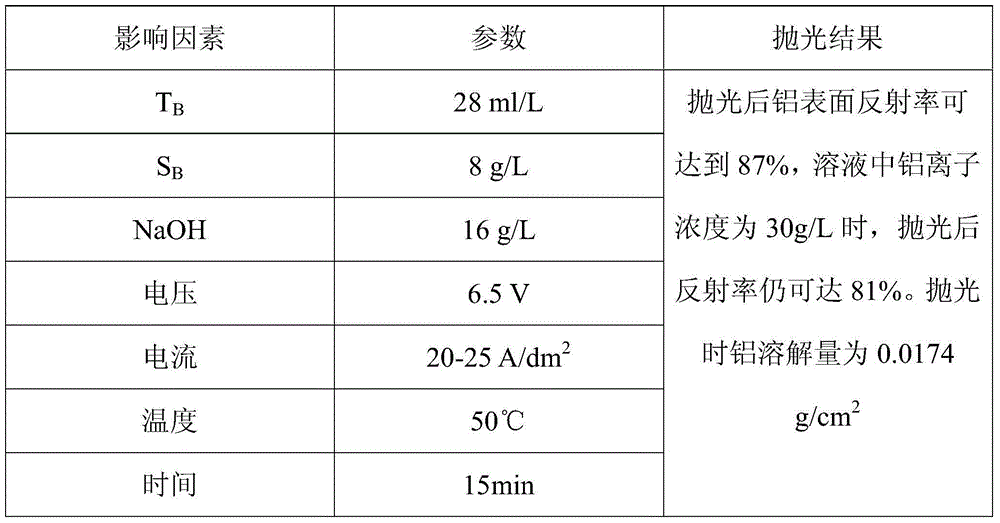

[0032] Example 2 with T B Be the performance detection of the polishing liquid of the present invention of brightener

[0033] The specific detection process is referring to embodiment 1, with T B The composition of the polishing liquid as the main brightener, the parameters of the polishing process used and the polishing effect are shown in Table 2.

[0034] Table 2, with T B Polishing test results of the main brightener

[0035]

[0036] Table 2 for T B Brightener, S B The test results obtained for the stabilizer. where T A with T B The mechanism of action may be similar; while S B It has a strong complexing effect and can inhibit the hydrolysis of aluminum salts, thereby prolonging the service life of the solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com