Automatic arc slab rough grinding machine

A circular arc plate, automatic technology, applied in grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of high technical requirements of operators, restrictions on the application of curved stone, harsh grinding sound, etc. Achieve high technical requirements, ensure simple and easy processing size, and the effect of grinding sound is harsh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

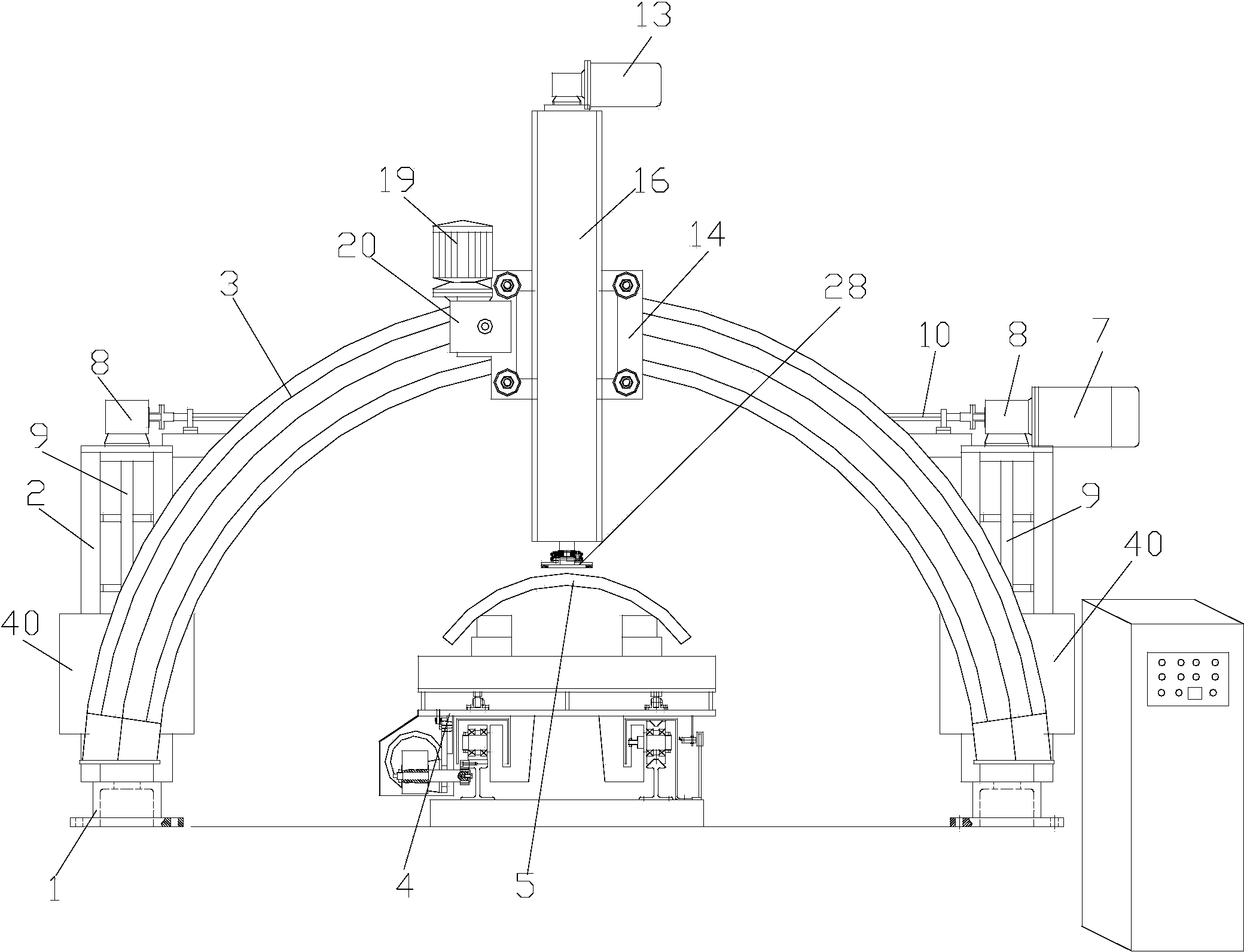

[0022] Attached below figure 1 An embodiment of the present invention is described.

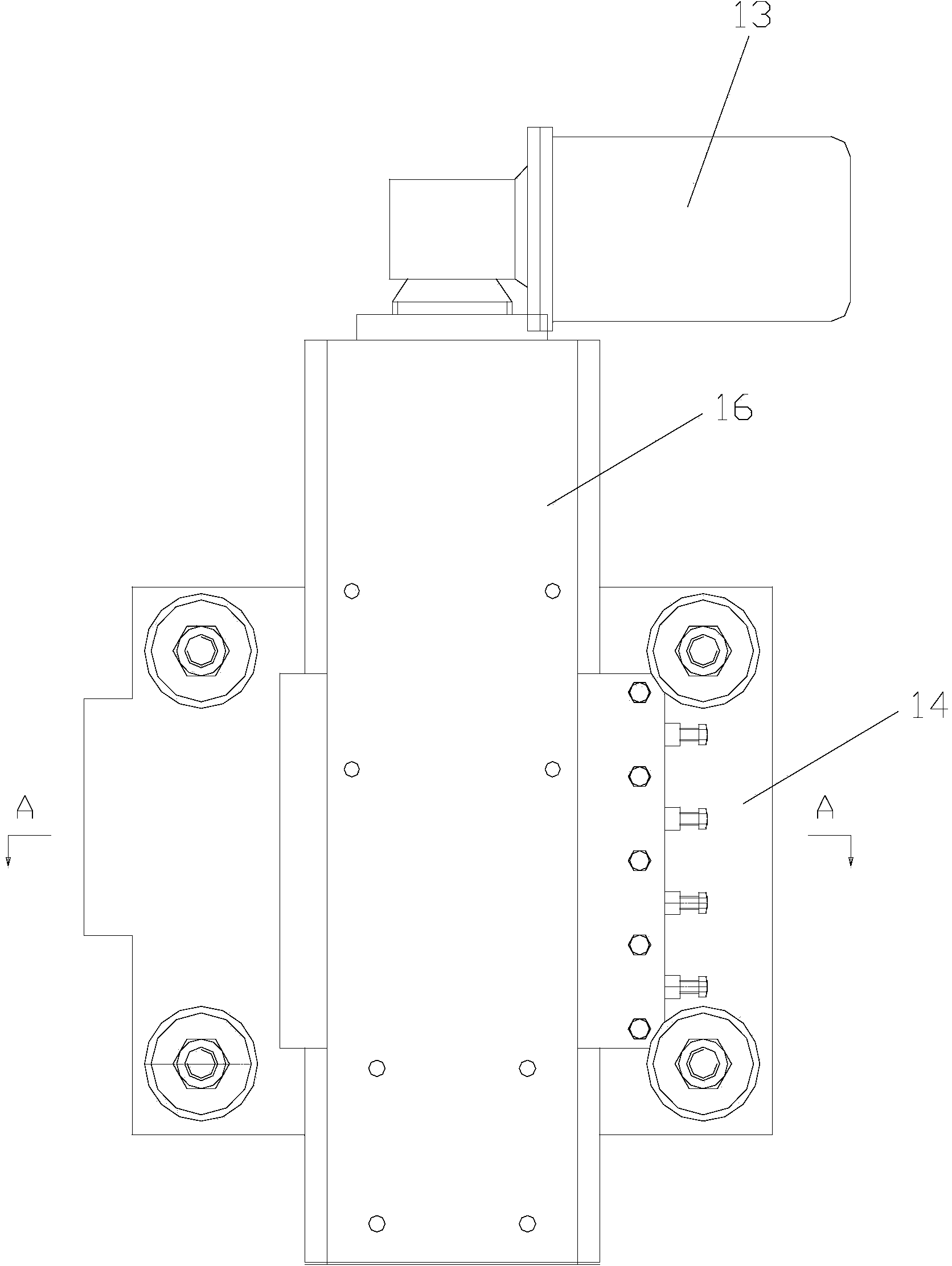

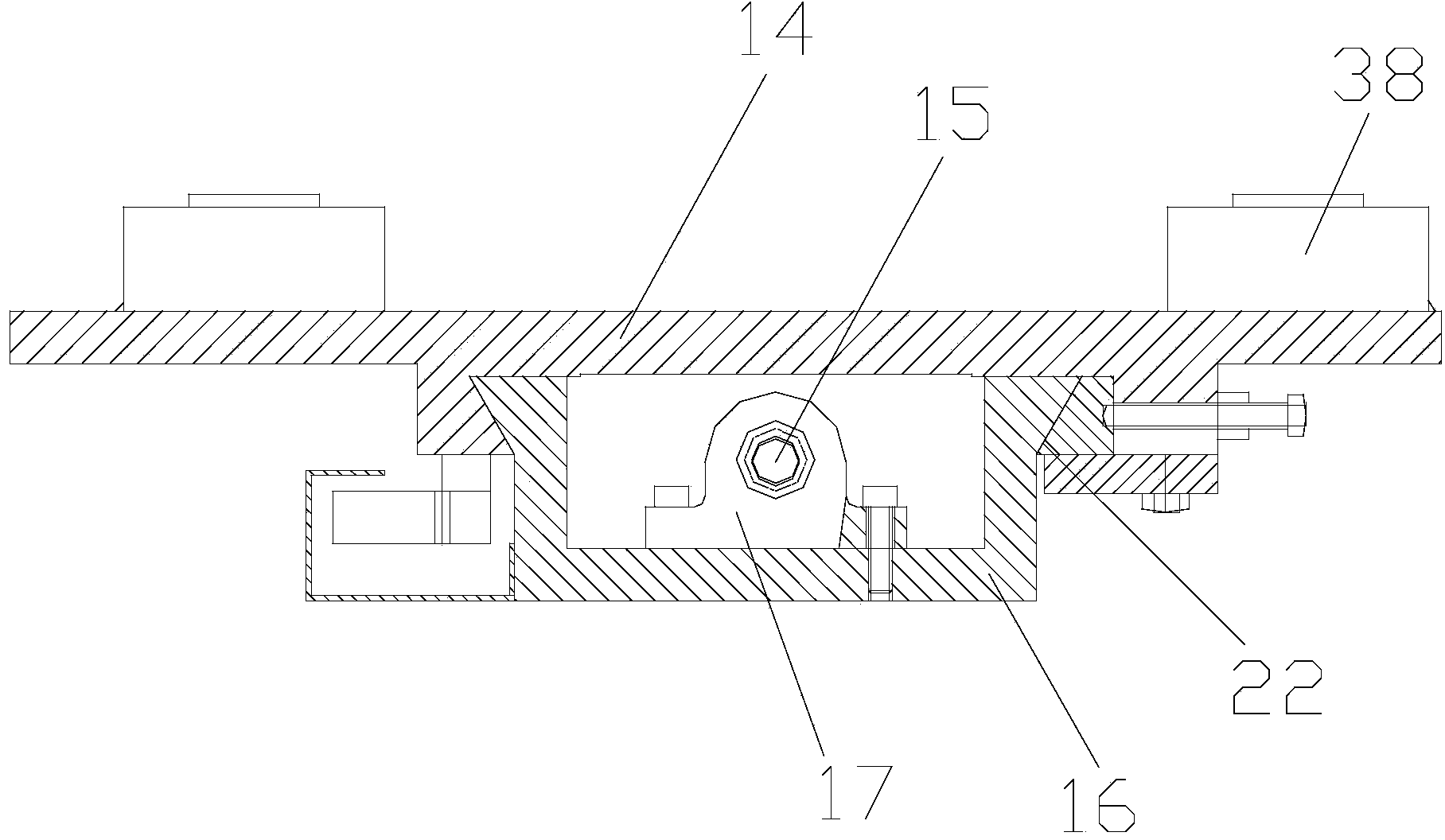

[0023] The arc plate automatic rough grinding machine has a base 1, a column 2, an arch beam 3, and an adjustable workbench 4 located in the middle of the base 1. Specifically, the adjustable workbench 4 includes a base 31, a support frame 32, and a clamp The tight frame 33, the movable seat 34 and the table vertical motor 35, the support frame 32 is fixed on the upper end surface of the base 31, the support frame 32 is made with a track, and the movable seat 34 is arranged on the upper end of the support frame 32 and It slides along the support frame 32 under the drive of the workbench vertical motor 35. The clamping frame 33 is located on both sides of the end surface of the movable seat 34. The clamping screw 37 with opposite screw threads is connected to the two clamps respectively. The shaft sleeve 18 at the lower end of the tightening frame 33 is screwed together, and the middle of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com