Hydraulic intermittent motion mechanism

A motion mechanism, hydraulic technology, applied in the direction of transmission, mechanical equipment, fluid transmission, etc., can solve the problem that the intermittent mechanism cannot adapt to heavy load, and achieve the effect of favorable lubrication, good movement stability and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

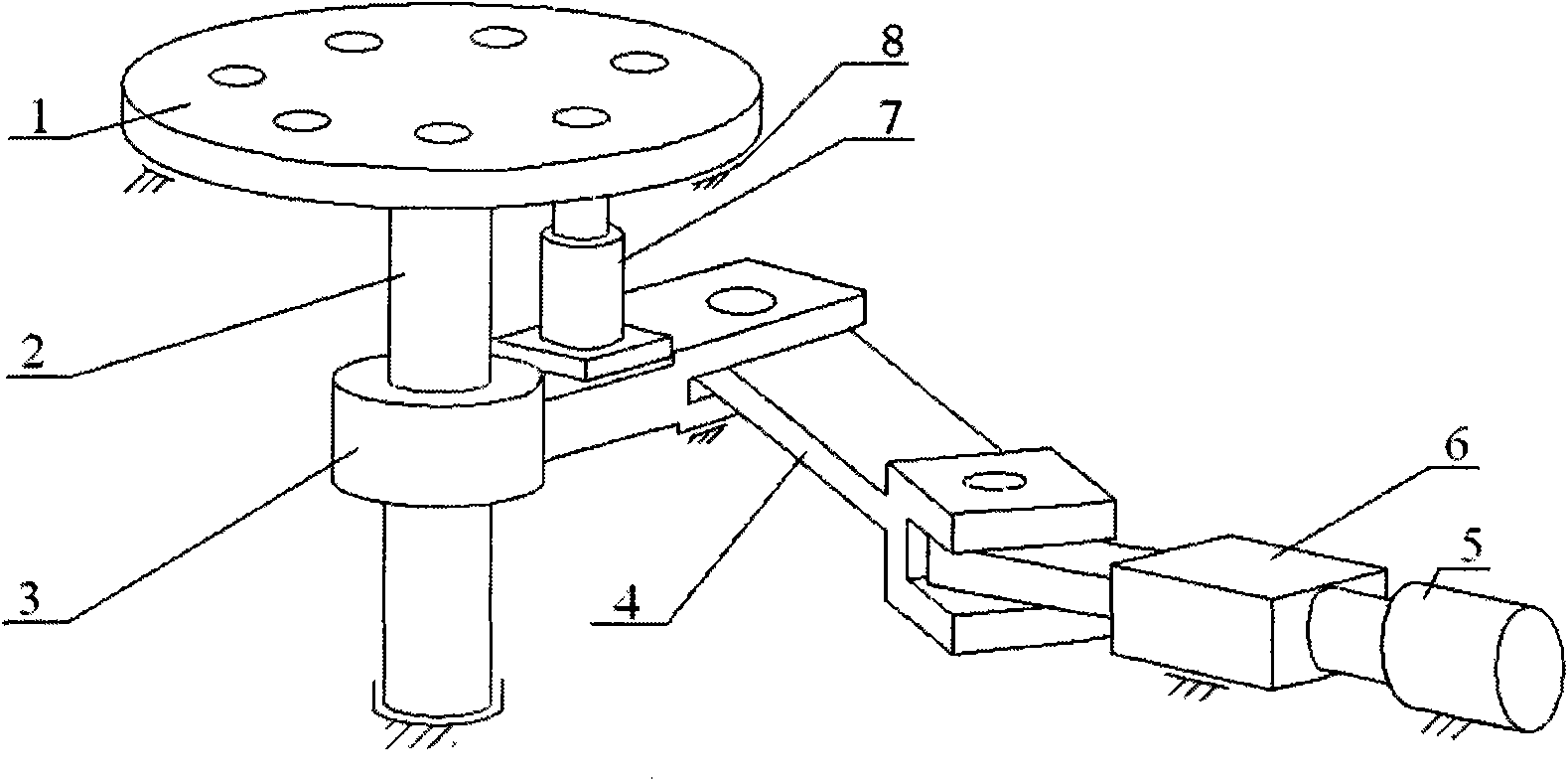

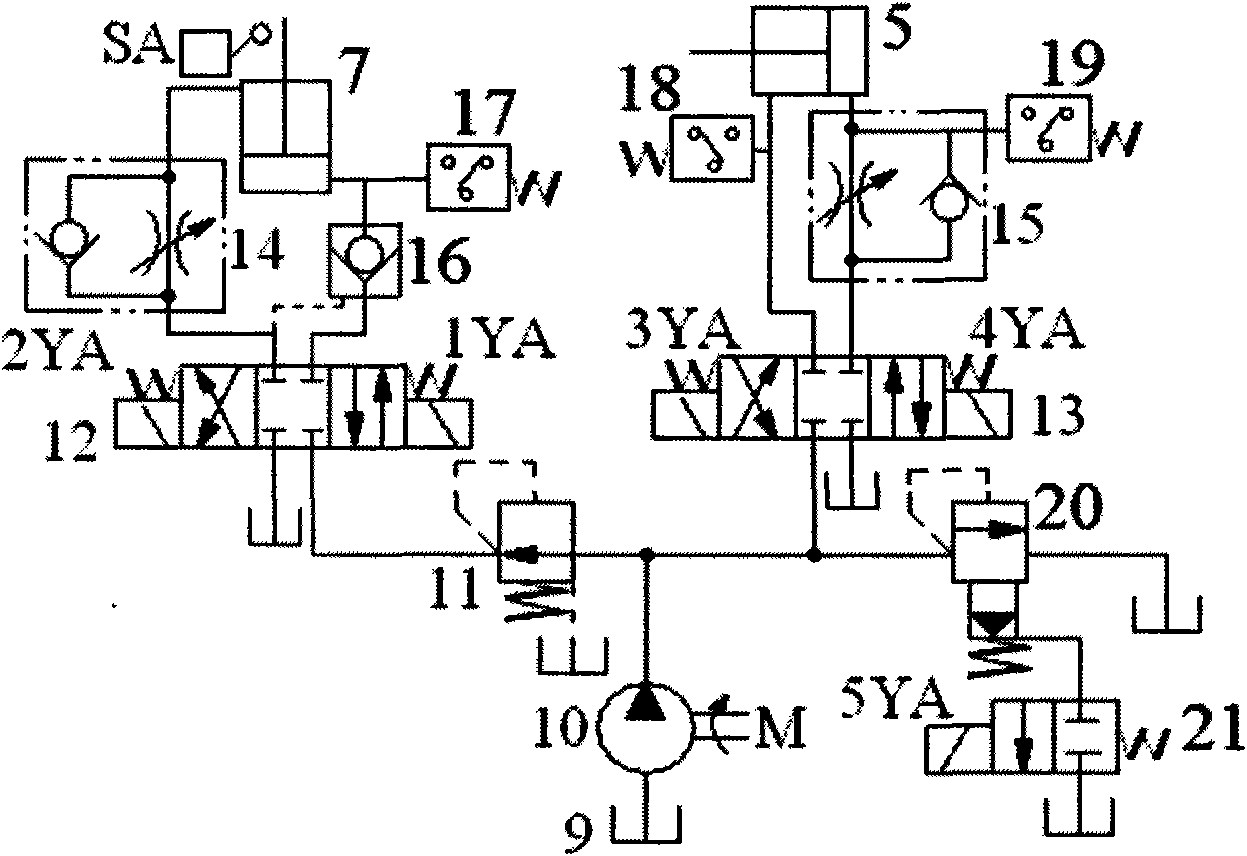

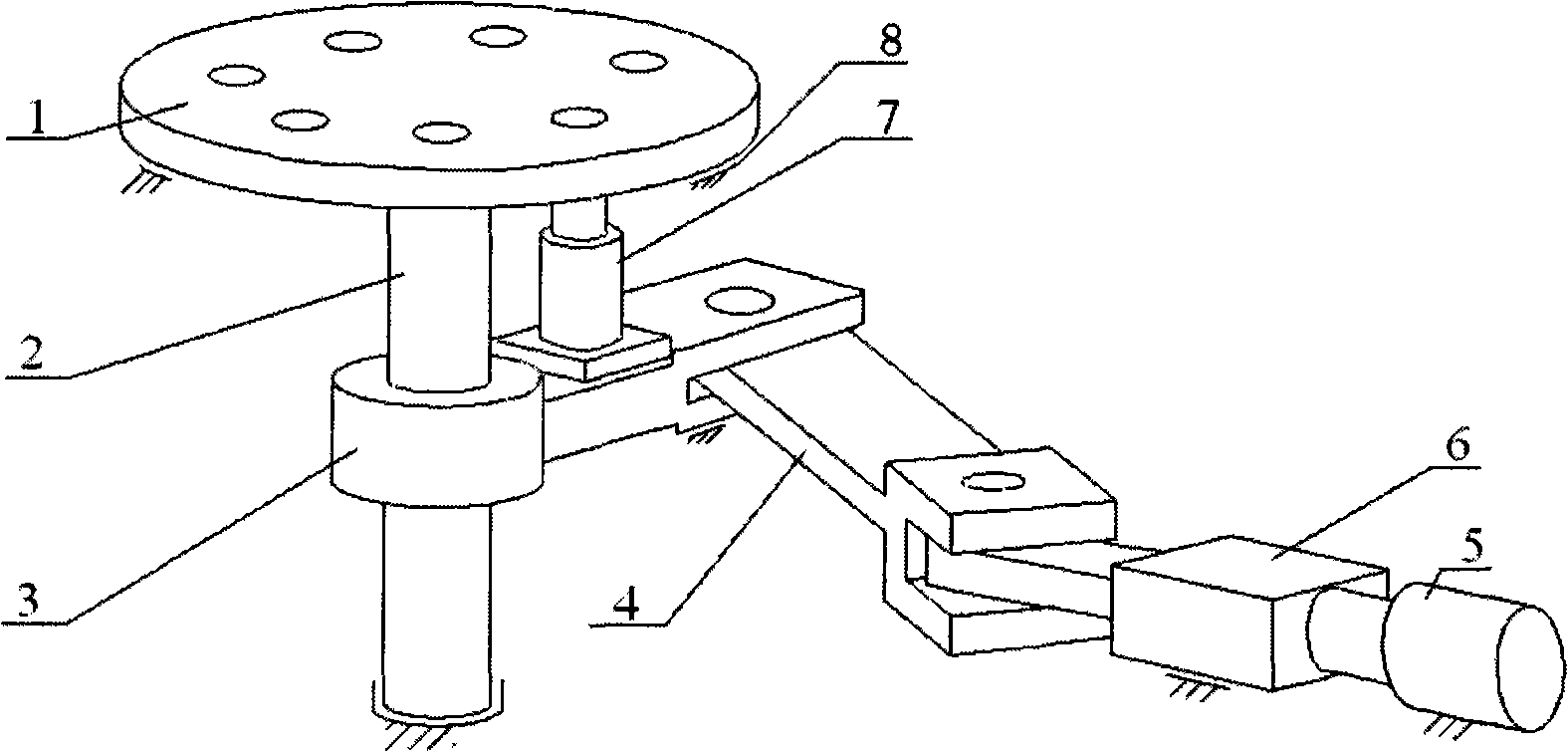

[0023] Such as figure 1 As shown, the intermittent motion mechanism is composed of a mechanical motion device and a hydraulic transmission device. The mechanical motion device includes a rotating platform 1, a rotating column 2, a swing rod 3, a connecting rod 4, an active hydraulic cylinder 5, a slide Block 6, pin hydraulic cylinder 7, and frame 8 are processed on the rotating platform 1 according to the actual situation. Several taper pin holes arranged according to the specific rotation angle are processed, and the rotating platform 1 and the rotating column 2 are fastened and connected and installed on the frame 8. Above, the rotating platform 1 and the rotating column 2 have relative movement with the frame 8, one end of the swing rod 3 is connected with the rotating column 2 to form a rotating pair, the bolt hydraulic cylinder 7 is fixed on the swing rod 3, the other end of the swing rod 3 is connected with the connecting rod 4 is hinged, the swing rod 3 and the frame 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com