Bamboo chip conveying device

A conveying device and a technology of bamboo chips, which are applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve problems such as scratching the hands of the handling personnel, threats to the personal safety of workers, and failure to meet the use requirements, etc., and achieve manual labor intensity Large size, high work efficiency, accurate and fast counting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

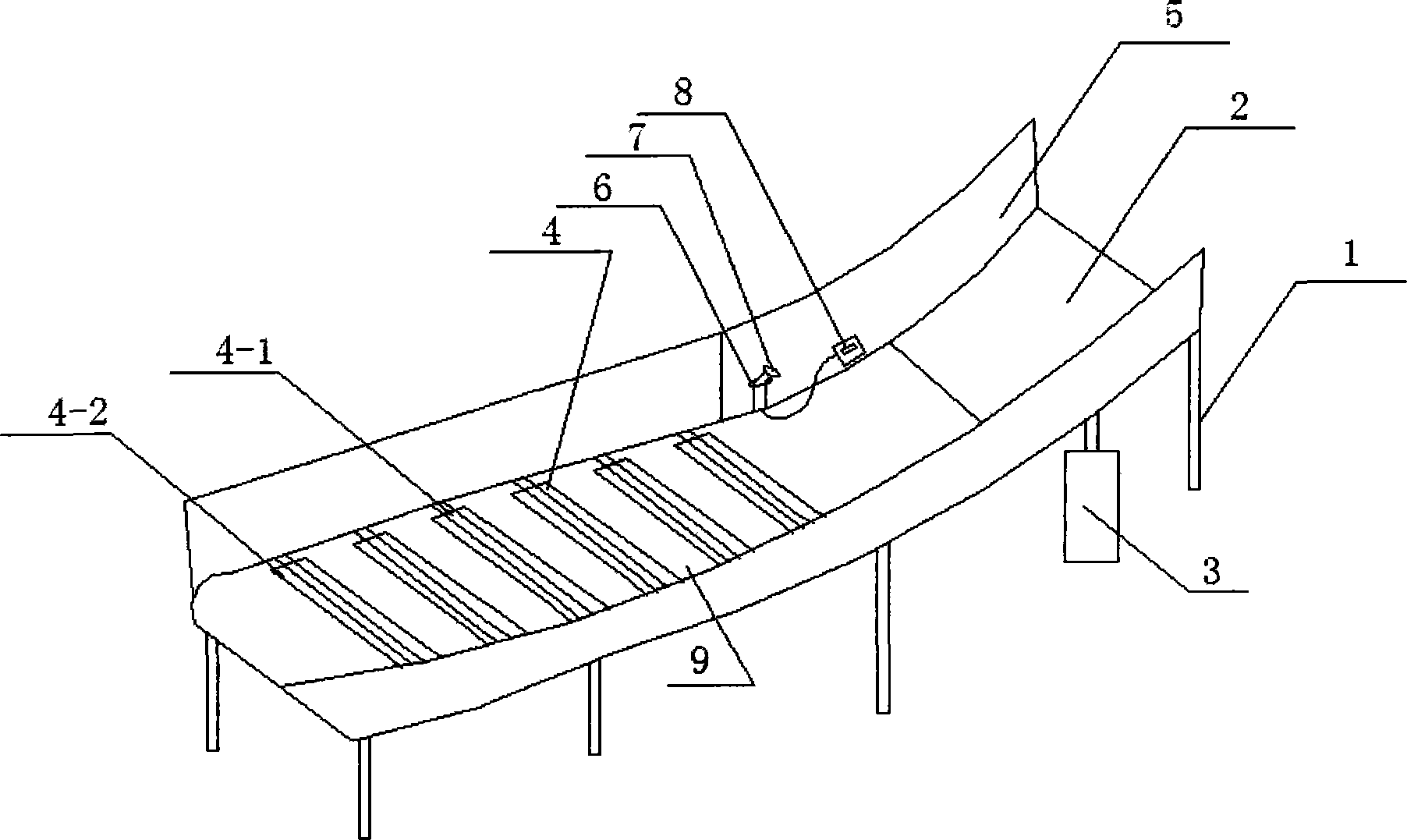

[0014] Embodiment 1: slicer cuts a section of bamboo tube into 6 slices at a time, and 6 slices of bamboo slices come down simultaneously on the vibrating conveyor belt 2, and the vibrating conveyor belt 2 is driven by the vibrating motor 3 to disperse the 6 slices of bamboo slices, and the slicer then The bamboo slices are cut and put on the vibrating conveyor belt 2. At the same time, the previous batch of 6 bamboo slices are transferred to the conveyor belt 9. The quantity of the bamboo slices is displayed one by one on the counter 8, and the second batch of bamboo slices is also transmitted to the conveyor belt 9 at the same time, and the third batch of bamboo slices is cut from the slicer again, and the transmission time of the transmission device once is 5 seconds, 100 bamboo pieces can be sent between 25 seconds and 30 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com