Integrated device with automatic box sealing and nailing functions

An automatic and functional technology, applied in the direction of transportation and packaging, packaging, transportation packaging, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive manual work, etc., to achieve the effect of improving production efficiency, saving production costs, and satisfying automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

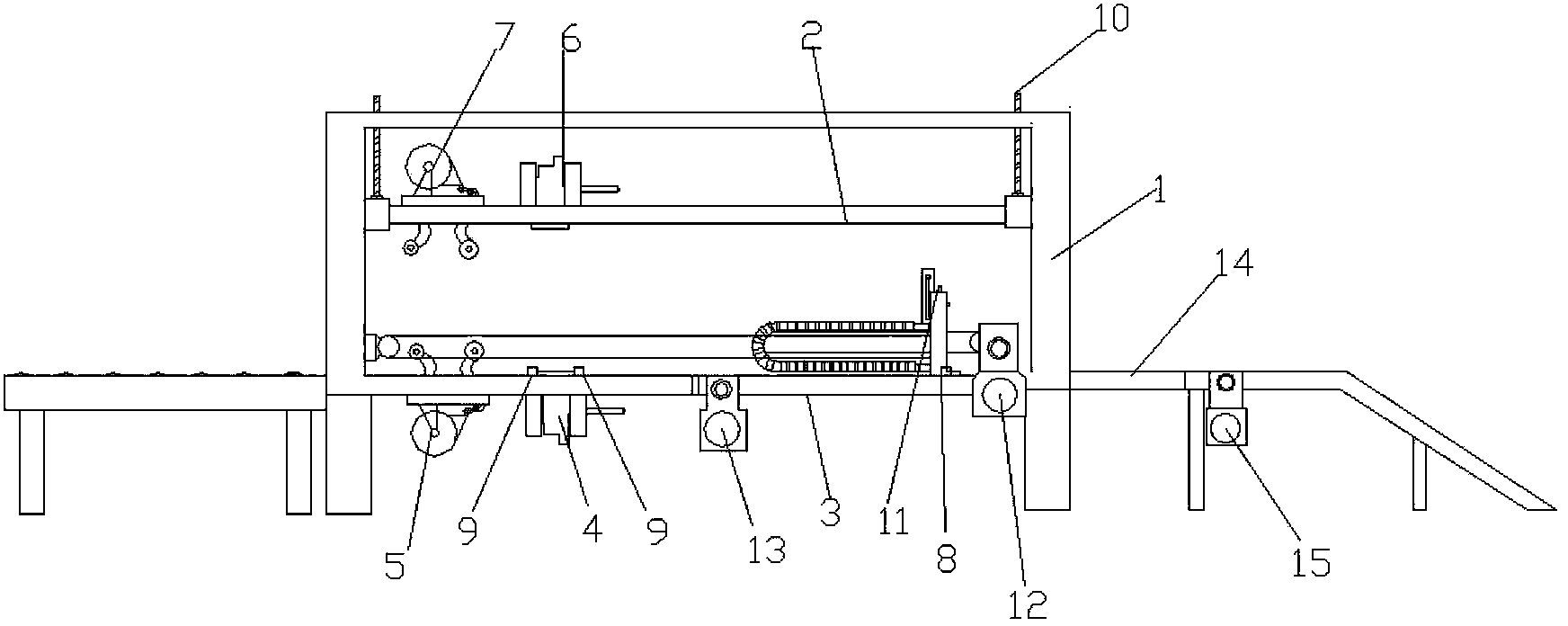

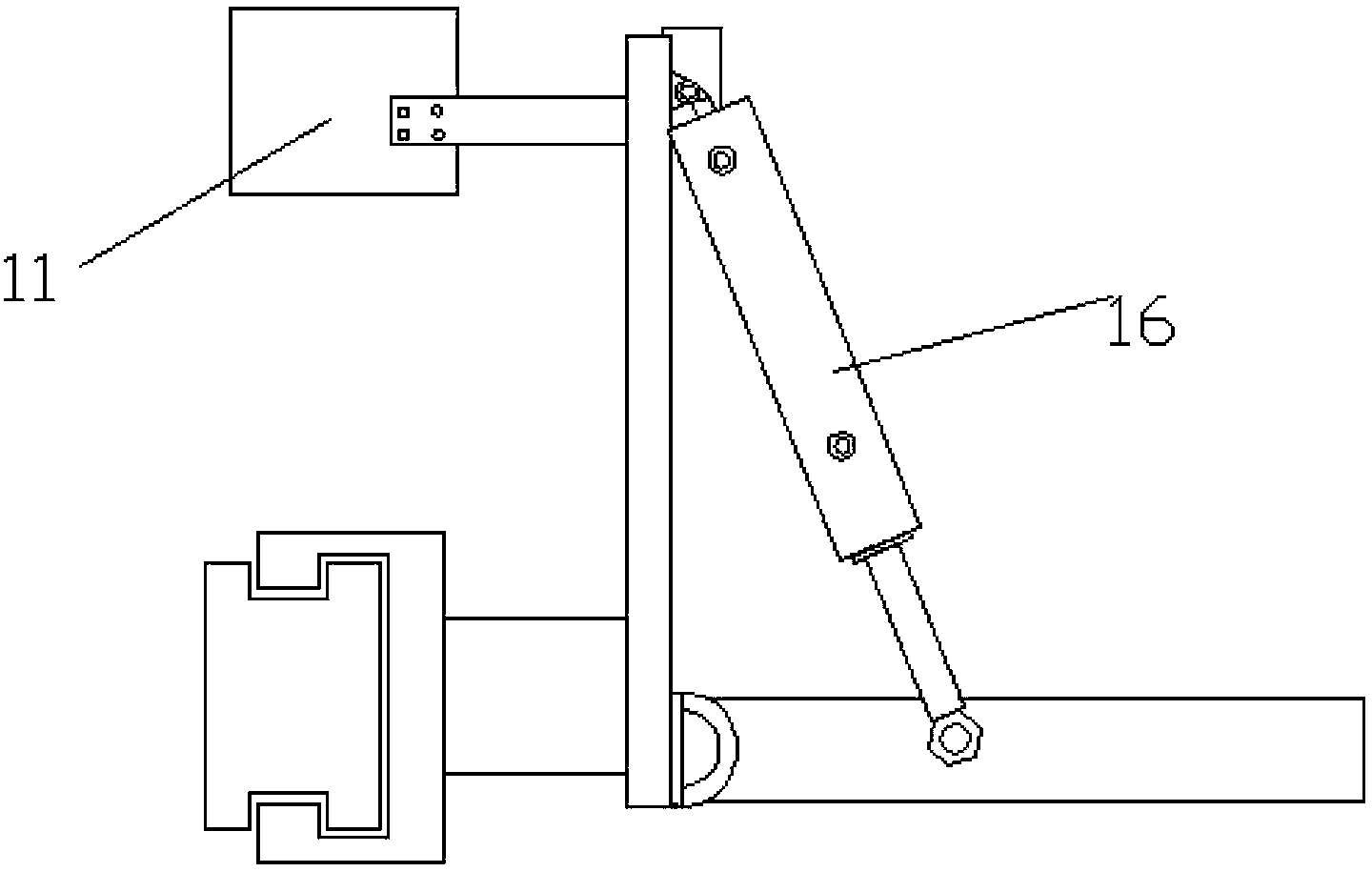

[0023] Such as figure 1 and figure 2 As shown, an integrated device with automatic sealing and nailing functions includes a transmission frame 1, and the transmission frame is fixed with an upper working support 2 and a lower working support 3 opposite up and down. The distance of the support relative to the lower working support is adjustable; the lower working support is provided with a working table, a lower automatic nailing machine 4, a lower automatic sealing tape machine 5 and a push mechanism, which are compatible with the lower automatic nailing machine and the The lower automatic sealing tape machine is opposite, and the upper automatic nailing machine 6 and the upper automatic sealing tape machine 7 are fixed on the upper working support; a main controller, a first photoelectric sensor 8 and several second photoelectric sensors are also provided. 9. The main controller can control the pushing mechanism to push the carton to be packed to move a certain distance thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com