Multi-pin-based defect detection device and detection method thereof

A defect detection and detection method technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as low automation and low detection efficiency, improve production efficiency, and reduce production costs. , the effect of meeting the needs of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

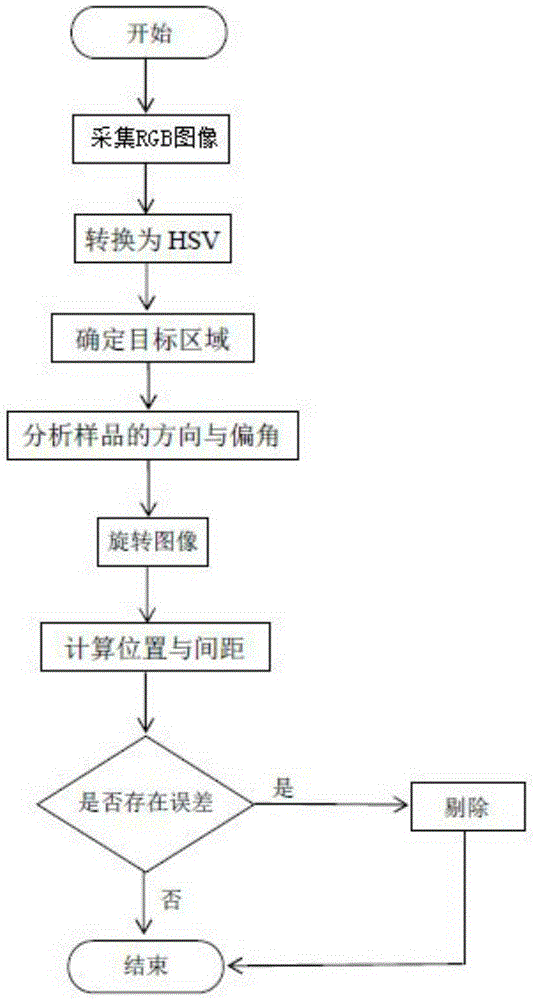

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

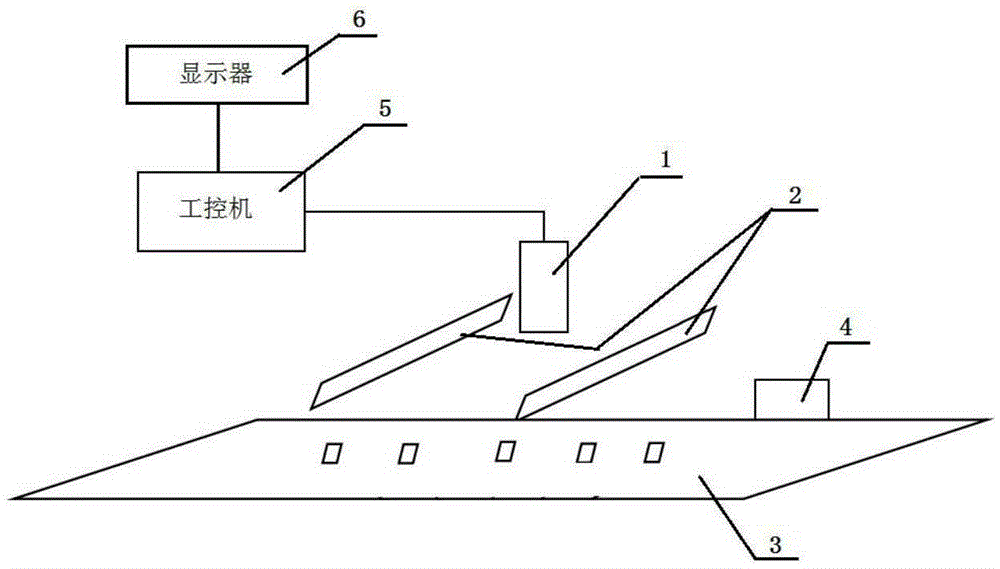

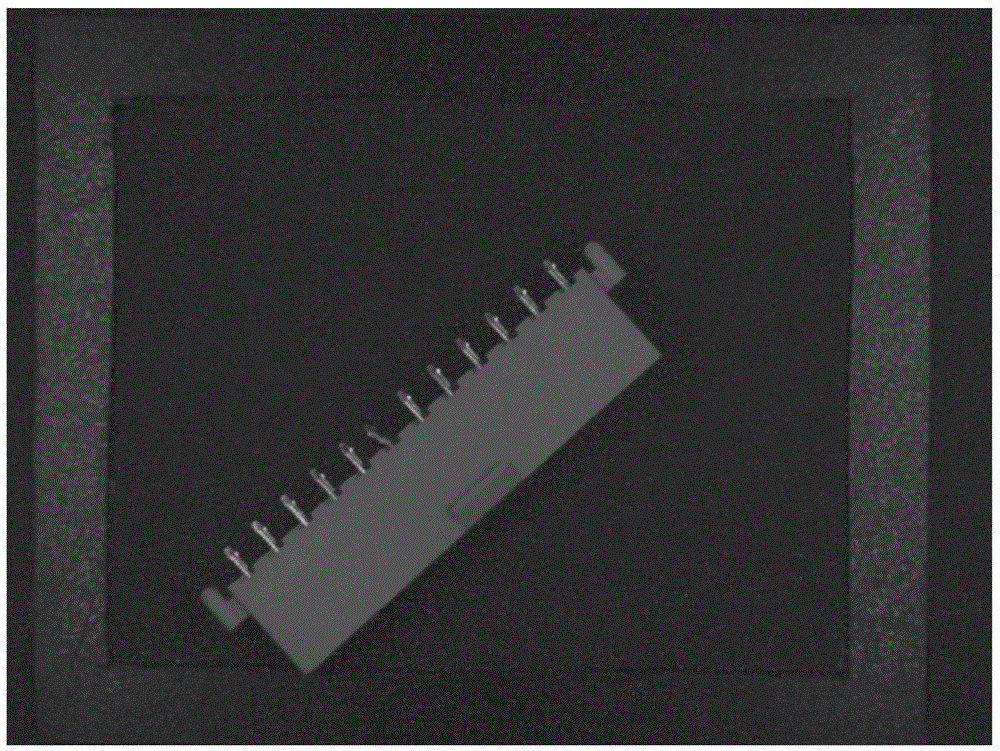

[0037] Such as figure 1 , figure 2 As shown, the present invention discloses a multi-pin-based defect detection device, which includes a camera 1 for collecting sample images, and two LED light sources 2 using high-angle lighting are symmetrically arranged under the camera 1. Below the LED light source 2, there is a transmission platform 3 for placing and transporting samples, and the side of the transmission platform 3 is provided with a rejection mechanism 4 for rejecting unqualified samples; the camera 1 is used to receive and process the collected samples. The industrial computer 5 for the image is connected, and the industrial computer 5 is also connected with a display 6 for displaying the image processing result made by the industrial computer 5 .

[0038] The conveying platform 3 is a belt conveying platform.

[0039] The rejecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com